Preparation method of doped nano-zinc germanate and its catalytic reduction of carbon dioxide

A technology of nano-germanium and zinc acid, applied in the direction of carbon monoxide, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of reducing the band gap width, and achieve the effects of reducing recombination, reducing energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

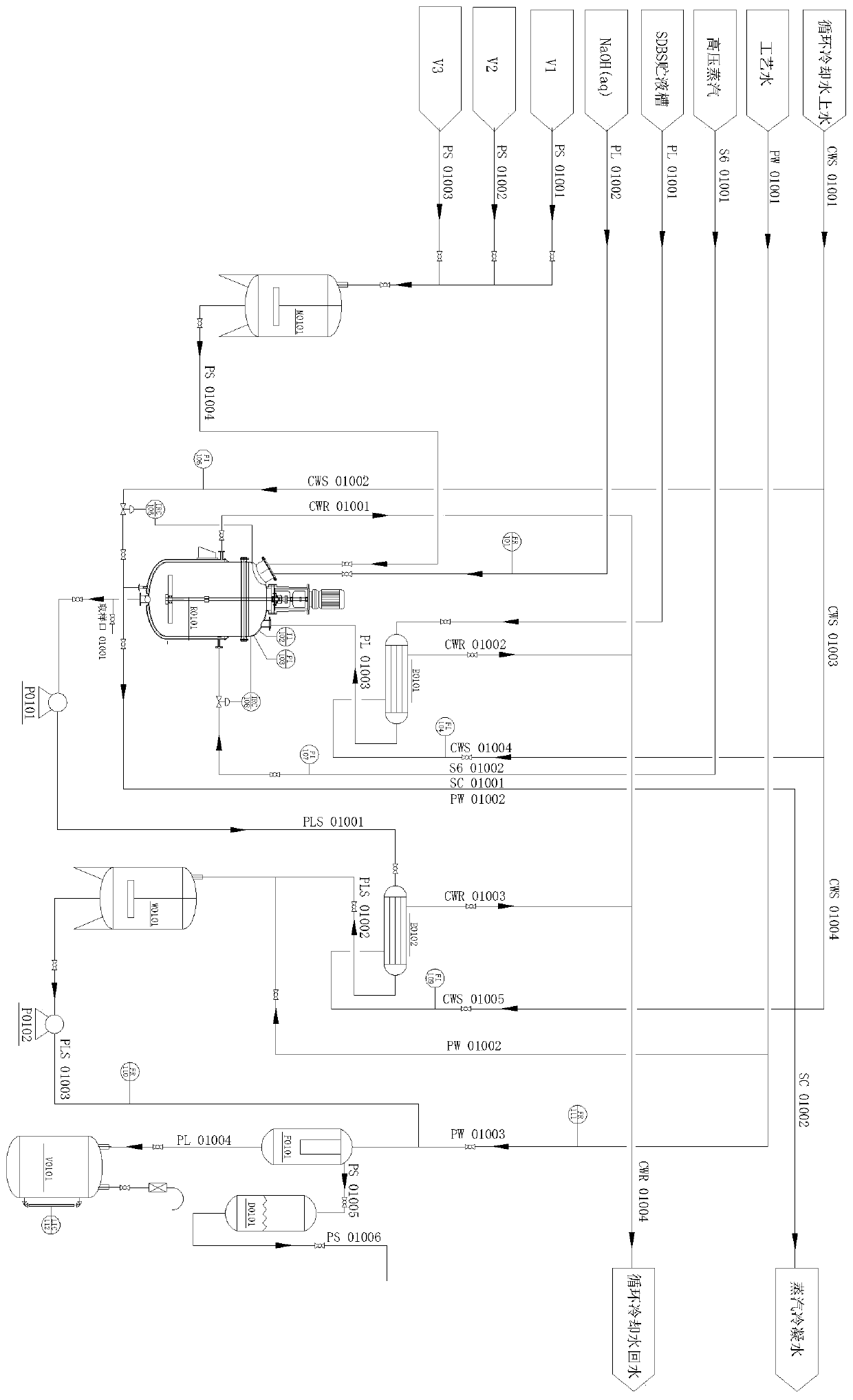

Embodiment 1

[0036] Zinc acetate, copper acetate and germanium oxide are mixed in a molar ratio of 1:0.03:0.97, placed in a raw material storage tank and mixed evenly. Dissolve sodium dodecylbenzenesulfonate with a molar ratio of 1:1 to zinc acetate in a certain amount of water, stir and mix evenly in the storage tank. Transport the water dissolved in sodium dodecylbenzene sulfonate to the reactor by the material pump, and then transport the uniformly mixed zinc acetate, copper acetate and germanium oxide to the reactor, stir for 30 minutes, and then add sodium hydroxide The pH of the solution was adjusted to 11.0. The reaction was carried out at 100°C for 10 hours, and the product was washed with water until neutral. Perform vacuum drying.

Embodiment 2

[0038]Zinc acetate, copper acetate and germanium oxide are mixed in a molar ratio of 1:0.06:0.93, placed in a raw material storage tank and mixed evenly. Dissolve sodium dodecylbenzenesulfonate with a molar ratio of 1:1.2 to zinc acetate in a certain amount of water, stir and mix evenly in the storage tank. The water dissolved in sodium dodecylbenzenesulfonate is transported to the reactor by the material pump, and then the uniformly mixed zinc acetate, copper acetate and germanium oxide are transported to the reactor, and after stirring for 30 minutes, add sodium hydroxide The pH of the solution was adjusted to 9.0. The reaction was carried out at 180°C for 4 hours, and the product was washed with water until neutral. Perform vacuum drying.

Embodiment 3

[0040] Zinc acetate, copper acetate and germanium oxide are mixed in a molar ratio of 1:0.06:0.93, placed in a raw material storage tank and mixed evenly. Dissolve sodium dodecylbenzenesulfonate with a molar ratio of 1:1.4 to zinc acetate in a certain amount of water, stir and mix evenly in the storage tank. Pump the water dissolved in sodium dodecylbenzene sulfonate to the reaction kettle, and then transfer the uniformly mixed zinc acetate, copper acetate and germanium oxide to the reaction kettle, stir for 30 minutes, and then add sodium hydroxide solution Adjust the pH value to 10.5. The reaction was carried out at 120°C for 3.5 hours, and the product was washed with water until neutral. Perform vacuum drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com