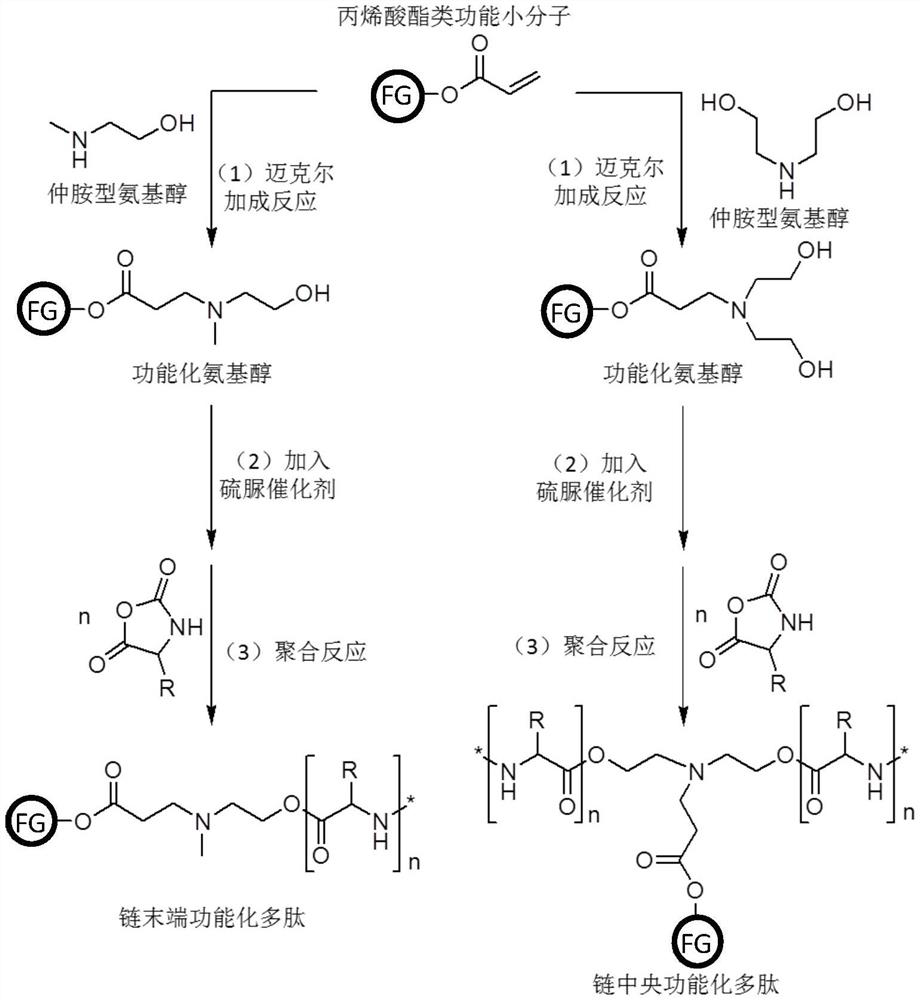

One-pot method for preparing functionalized polypeptides

A functionalized, polypeptide technology, applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of the inability to achieve the molecular weight of the polypeptide, the controllability of the polymerization reaction, and the binding of the polypeptide, etc. Controllable topology, high catalytic activity, and cheap and easy-to-obtain reaction raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

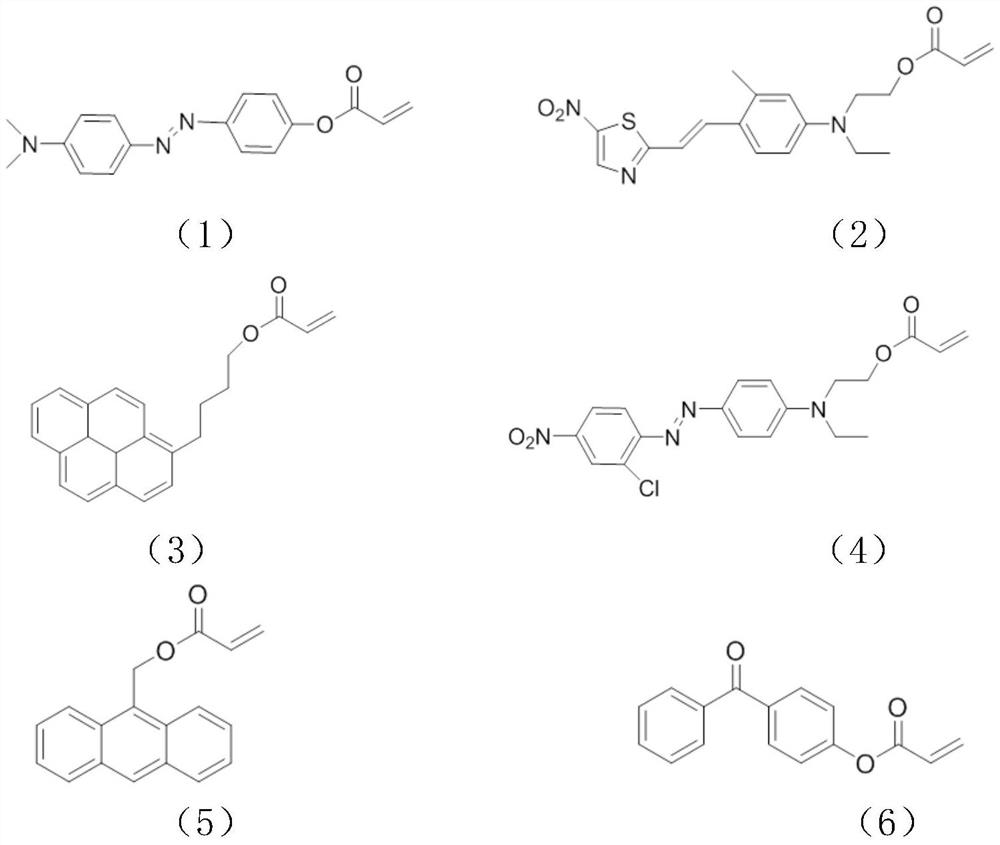

Method used

Image

Examples

Embodiment 1

[0038] At room temperature, add 37.99 μmol of acrylate functional small molecules, 37.99 μmol of secondary amine-type amino alcohol and 10 ml of organic solvent methylene chloride into a 25 ml polymerization bottle that has undergone anhydrous treatment, react at 25°C for 10 minutes, and then add 37.99μmol of thiourea catalyst, after stirring for 5min, add 1.90mmol of amino acid anhydride monomer into the polymerization bottle, and then after 0.2h of polymerization reaction at 25°C, add ethanol with a volume fraction of 10% hydrochloric acid into the polymerization bottle The solution terminated the reaction, the reaction solution was poured into ethanol to settle, filtered to obtain a white solid, the solid was placed in a drying oven, and dried at 40°C for 48 hours to obtain a solid with a net weight of 0.41g. The amino acid ring was detected by infrared testing. The conversion rate of the acid anhydride monomer, the result shows that the conversion rate of the monomer is 99%...

Embodiment 2

[0040] At room temperature, add 37.99 μmol of acrylate functional small molecules, 37.99 μmol of secondary amine-type amino alcohol and 10 ml of organic solvent THF to 25 ml of anhydrous-treated polymerization bottle, react at 25 °C for 10 minutes, and then add 37.99 μmol of Thiourea catalyst, after stirring for 5min, add 1.90mmol amino acid anhydride monomer in the polymerization bottle, then after 0.2h of polymerization at 25°C, add ethanol solution of hydrochloric acid with a volume fraction of 10% to the polymerization bottle to terminate reaction, the reaction solution was poured into ethanol to settle, filtered to obtain a white solid, the solid was placed in a drying oven, and dried at 40°C for 48 hours to obtain a solid with a net weight of 0.41g, and an infrared test was used to detect the acid anhydride monolayer in the amino acid ring. The results showed that the conversion rate of the monomer was 99%; the molecular weight Mn of the functionalized peptide was 10,900 ...

Embodiment 3

[0042]At room temperature, add 37.99 μmol of acrylate functional small molecules, 37.99 μmol of secondary amine-type amino alcohol and 10 ml of organic solvent DMF into a 25 ml polymerization bottle that has undergone anhydrous treatment, and then add 37.99 μmol Thiourea catalyst, after stirring for 5min, add 1.90mmol amino acid anhydride monomer in the polymerization bottle, then after 0.2h of polymerization at 25°C, add ethanol solution of hydrochloric acid with a volume fraction of 10% to the polymerization bottle to terminate reaction, the reaction solution was poured into ethanol to settle, filtered to obtain a white solid, the solid was placed in a drying oven, and dried at 40°C for 48 hours to obtain a solid with a net weight of 0.41g, and an infrared test was used to detect the acid anhydride monolayer in the amino acid ring. The results showed that the monomer conversion rate was 99%; the molecular weight Mn of the functionalized peptide was 10,900 and the molecular we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com