Phosphoric acid modified cerium oxide catalyst and its preparation method and application

A cerium oxide and catalyst technology, applied in the field of phosphoric acid modified cerium oxide catalyst and its preparation, can solve the problems of poor water resistance and sulfur resistance, low catalytic activity, poisoning and the like of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Catalyst preparation:

[0045] (1) Mix cerium oxide powder with phosphoric acid (concentration of phosphoric acid solution: 1 mol / L) at a molar ratio of 1:0.05, react at 30° C. for 0.5 h, cool the resulting mixture, let stand, and wash to obtain yellow cerium oxide precipitate.

[0046] (2) Wash the obtained mixture until it is neutral, dry it, and calcinate it at 200° C. for 1 h in an air atmosphere to obtain a catalyst.

[0047] The phosphorus loading of the prepared catalyst was 0.7%.

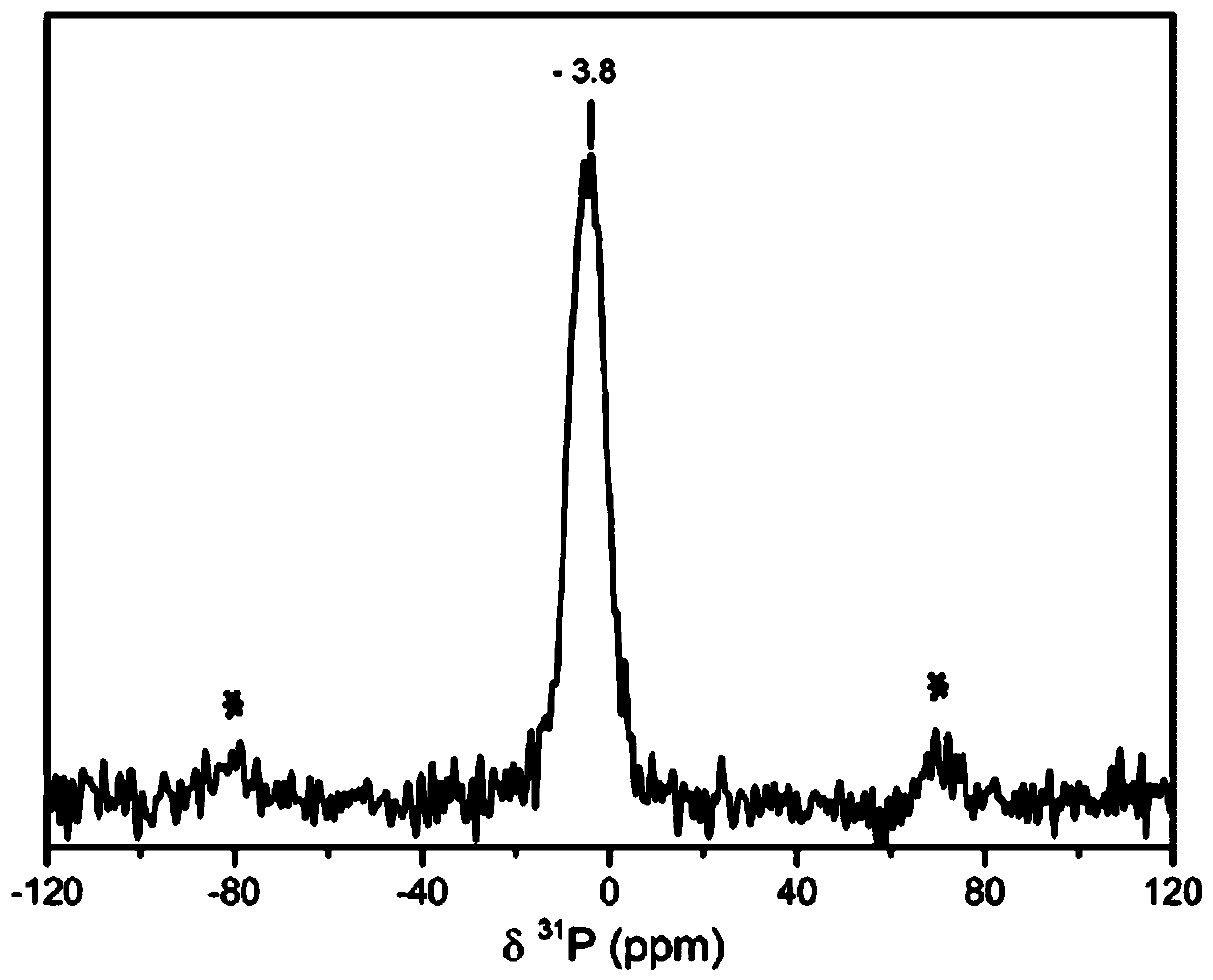

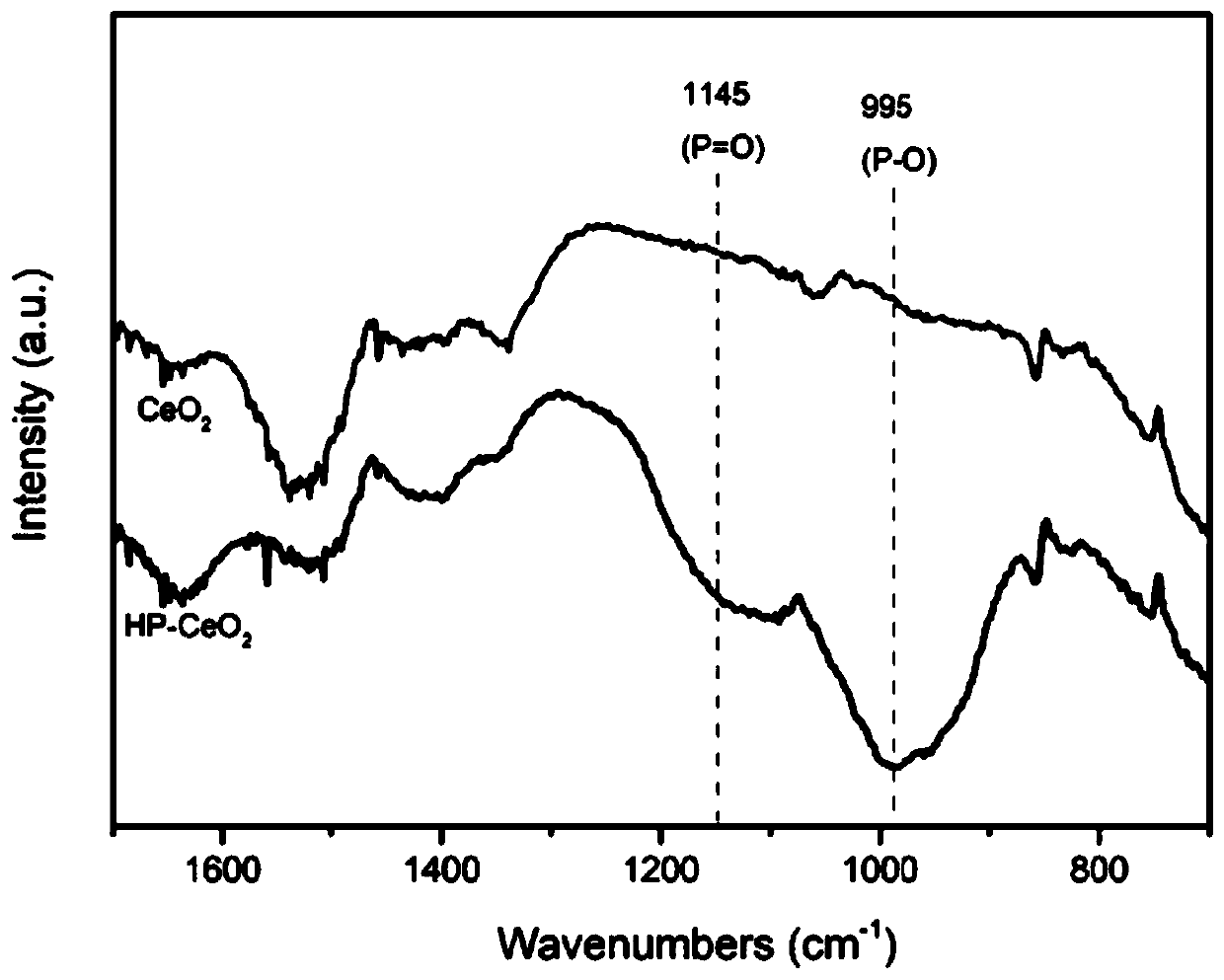

[0048] Such as figure 1 As shown, the presence of phosphate groups on the surface of ceria was proved by SS NMR characterization. Subsequent in situ infrared characterization as figure 2 As shown, it is also proved that P-O and P=O exist on the surface of cerium oxide after phosphoric acid treatment. After testing and characterization, the main form of phosphoric acid on the surface of the catalyst treated with phosphoric acid is dihydroxy phosphate.

Embodiment 2

[0050] Catalyst preparation:

[0051] (1) Mix cerium oxide powder and phosphoric acid at a molar ratio of 1:0.05, react at 80° C. for 0.5 h, cool the resulting mixture, let stand, and wash to obtain yellow cerium oxide precipitate.

[0052] (2) Wash the obtained mixture until it is neutral, dry it, and calcinate it at 200° C. for 1 h in an air atmosphere to obtain a catalyst.

[0053] The phosphorus loading of the prepared catalyst was 0.4%.

Embodiment 3

[0055] Catalyst preparation:

[0056] (1) Mix cerium oxide powder and phosphoric acid at a molar ratio of 1:0.05, react at 30° C. for 0.5 h, cool the resulting mixture, let stand, and wash to obtain yellow cerium oxide precipitate.

[0057] (2) Wash the obtained mixture until it is neutral, dry it, and calcinate it at 300° C. for 2 hours in an air atmosphere to obtain a catalyst.

[0058] The phosphorus loading of the prepared catalyst was 0.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com