Organic and inorganic hybridized lead iodide visible light catalysis material and preparation method thereof

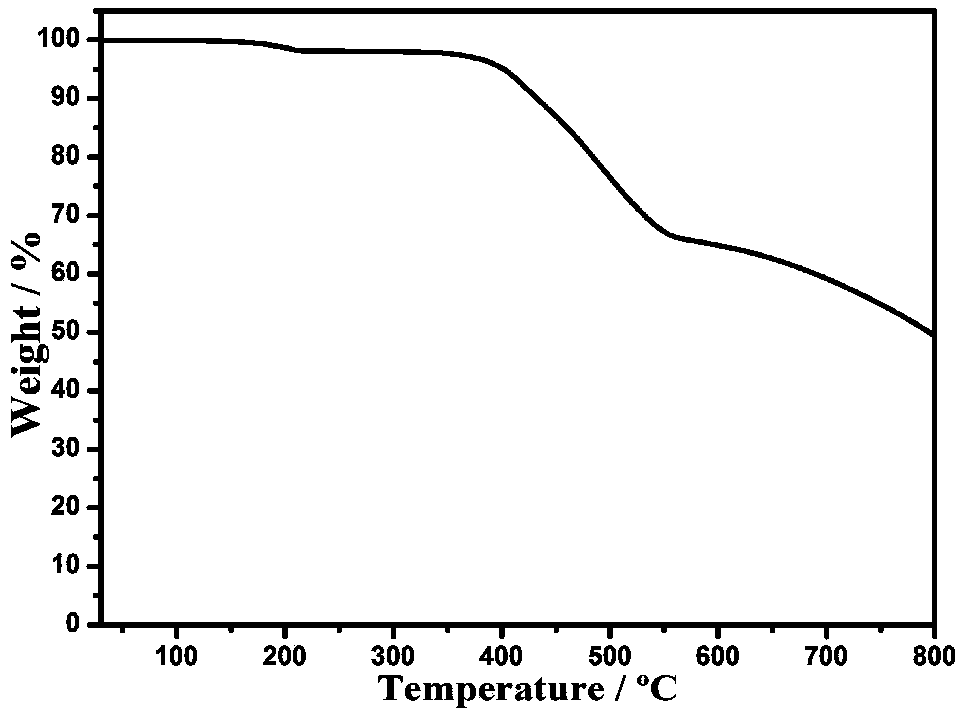

A catalytic material, visible light technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low photocatalytic efficiency and poor photochemical stability of lead iodide, etc. problem, to achieve the effect of stable visible light catalytic performance, good thermal stability, and good photochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the organic-inorganic hybrid lead iodide visible light catalytic material of the present invention comprises the following steps:

[0027] i) Weigh the raw material Fe(SO 4 )·7H 2 O, 2,2-bipyridine, PbI 2 and KI, add 0.5mLHI, 4mLN.N-dimethylformamide and 1mLH according to the molar ratio of 2:6:8:2 2 O in the mixed solution, then put the mixture into the reaction kettle and seal;

[0028] ii) Put the sealed hydrothermal kettle into an electric blast drying oven with programmed temperature control, heat it to 140°C for 5 hours, then react at a constant temperature of 140°C for 6 days, drop to room temperature, and the synthesis reaction ends;

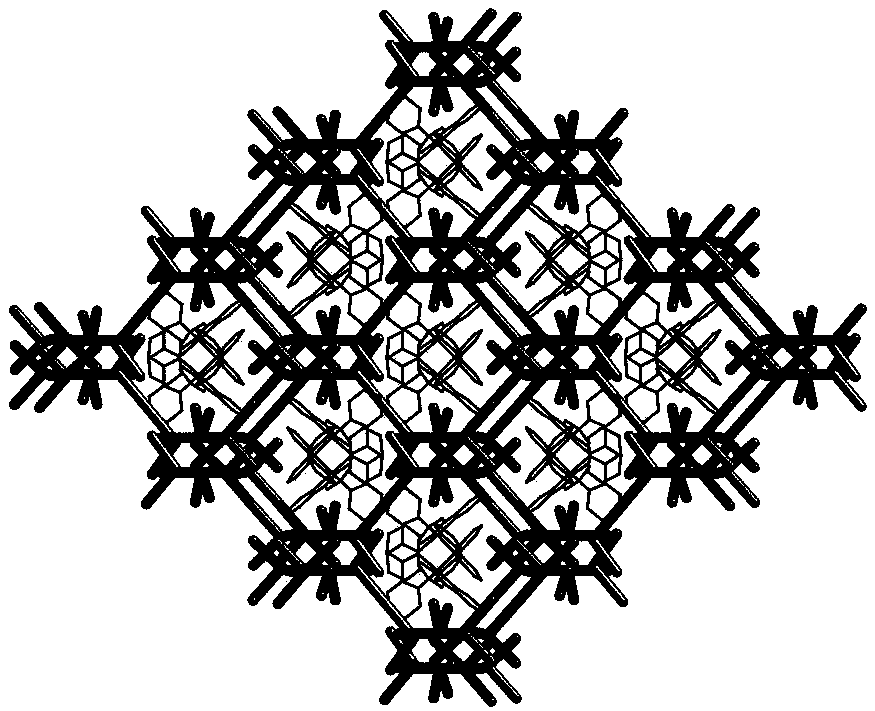

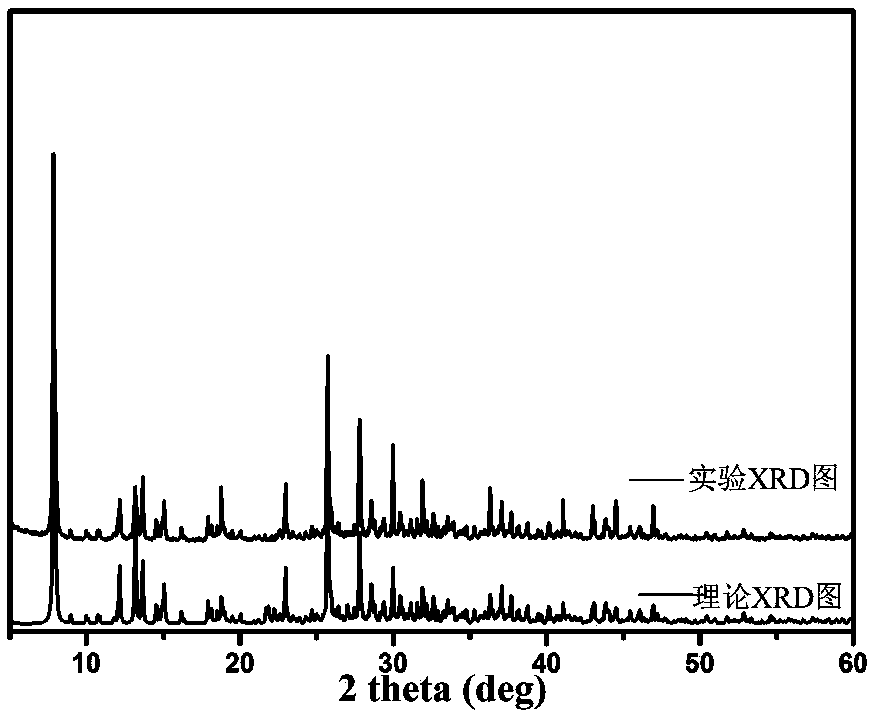

[0029] iii) Open the reaction kettle, carry out suction filtration to the solid-liquid mixture, and dry the material obtained by suction filtration to obtain a black-red block crystal material, which is the target compound [Fe(2.2-bipy) 3 ] 2 Pb 8 I21 . After washing with distilled water and ethano...

Embodiment 2

[0031] The preparation method of the organic-inorganic hybrid lead iodide visible light catalytic material of the present invention comprises the following steps:

[0032] i) Weigh the raw material Fe(SO 4 )·7H 2 O, 2,2-bipyridine, PbI 2 and KI, add 0.5mLHI, 4mLN.N-dimethylformamide and 1mLH according to the molar ratio of 2.5:6.5:8.5:2.5 2 O in the mixed solution, then put the mixture into the reaction kettle and seal;

[0033] ii) Put the sealed hydrothermal kettle into an electric blast drying oven with programmed temperature control, heat it to 140°C for 5 hours, then react at a constant temperature of 160°C for 8 days, drop to room temperature, and the synthesis reaction ends;

[0034] iii) Open the reaction kettle, carry out suction filtration to the solid-liquid mixture, and dry the material obtained by suction filtration to obtain a black-red block crystal material, which is the target compound [Fe(2.2-bipy) 3 ] 2 Pb 8 I 21 . After washing with distilled water ...

Embodiment 3

[0039] Figure 4 Shown is the compound [Fe(2.2-bipy) 3 ] 2 Pb 8 I 21 Absorbance curve of RhB under catalysis. 30mg [Fe(2.2-bipy) 3 ] 2 Pb 8 I 21 The sample is dispersed in a 30ml container with a concentration of 1×10 -5 mol / L Rhodamine B (RhB) solution in the quartz reactor, after dispersing in the ultrasonic cleaner for 30 minutes, put it into the dark room, and stir for 10 hours under the condition of no light, to ensure that RhB and the prepared photocatalytic material powder reach Adsorption-desorption equilibrium. After the adsorption-desorption equilibrium was reached, the photodegradation ability of the photocatalytic material on RhB was measured using a 500W xenon lamp as a visible light source. Take out 4mL test solution every 10min for analysis, stop after 60min of reaction. The concentration change of RhB was obtained by measuring the absorbance of the solution with an ultraviolet-visible spectrophotometer. Compound [Fe(2.2-bipy) 3 ] 2 Pb 8 I 21 Bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com