Industrialized production method and device for 2,5-dimethyl-2,5-hexylene glycol

A production method and technology of hexylene glycol are applied in chemical instruments and methods, preparation of hydroxyl compounds, organic chemistry, etc., and can solve the problems of inconvenient disposal of potassium chloride waste, strong corrosiveness, unstable quality of intermediate products, etc., and achieve environmental protection. Effect and economic benefit improvement, cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

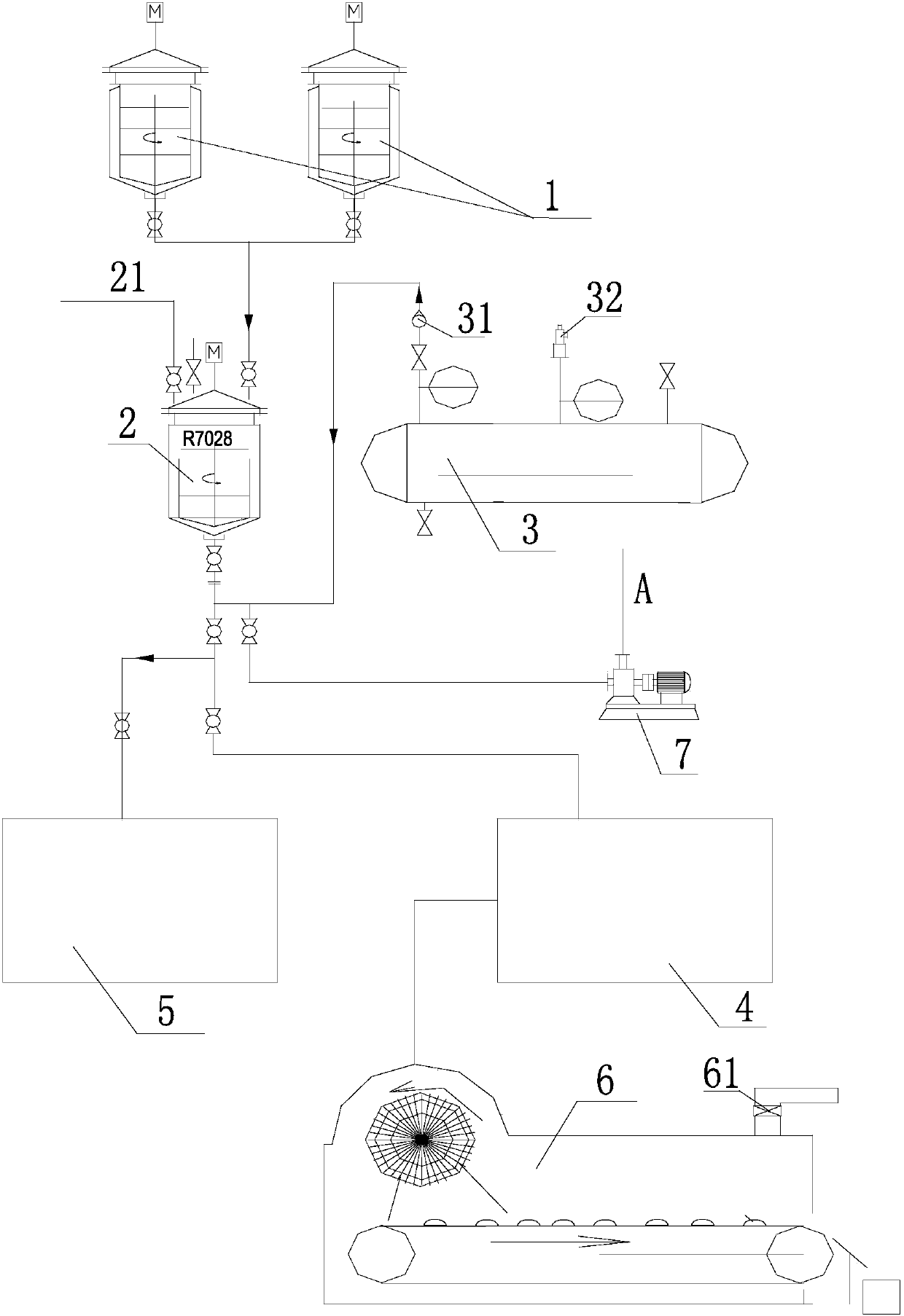

[0022] A kind of industrialized production device of 2,5-dimethyl-2,5-hexanediol, such as figure 1 Shown: including frame-type stirring alkynylation reaction kettle 1, enamel neutralization reaction kettle 2, horizontal carbon dioxide storage tank 3, potassium carbonate salt square receiving tank 4, carbon steel alkaline water square receiving tank 5, potassium carbonate vibration drying Recovery device 6 and benzene solution oil phase pump 7, said enamel neutralization reactor 2 upper end is also provided with vent pipe 21; said carbon dioxide horizontal storage tank 3 is also provided with carbon dioxide spring type decompression device 31 and carbon dioxide pressure Sensing pressure relief device 32, described potassium carbonate rotary drying recovery device 6 is also provided with induced draft fan 61; Wherein, described acetylenization reactor 1 bottom is connected with neutralization reactor 2 top by pipeline, The carbon dioxide storage tank 3 is connected with the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com