Double-component water-based polyurethane coating for woodware

A water-based polyurethane, two-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor water resistance and achieve excellent alcohol resistance, high hardness, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

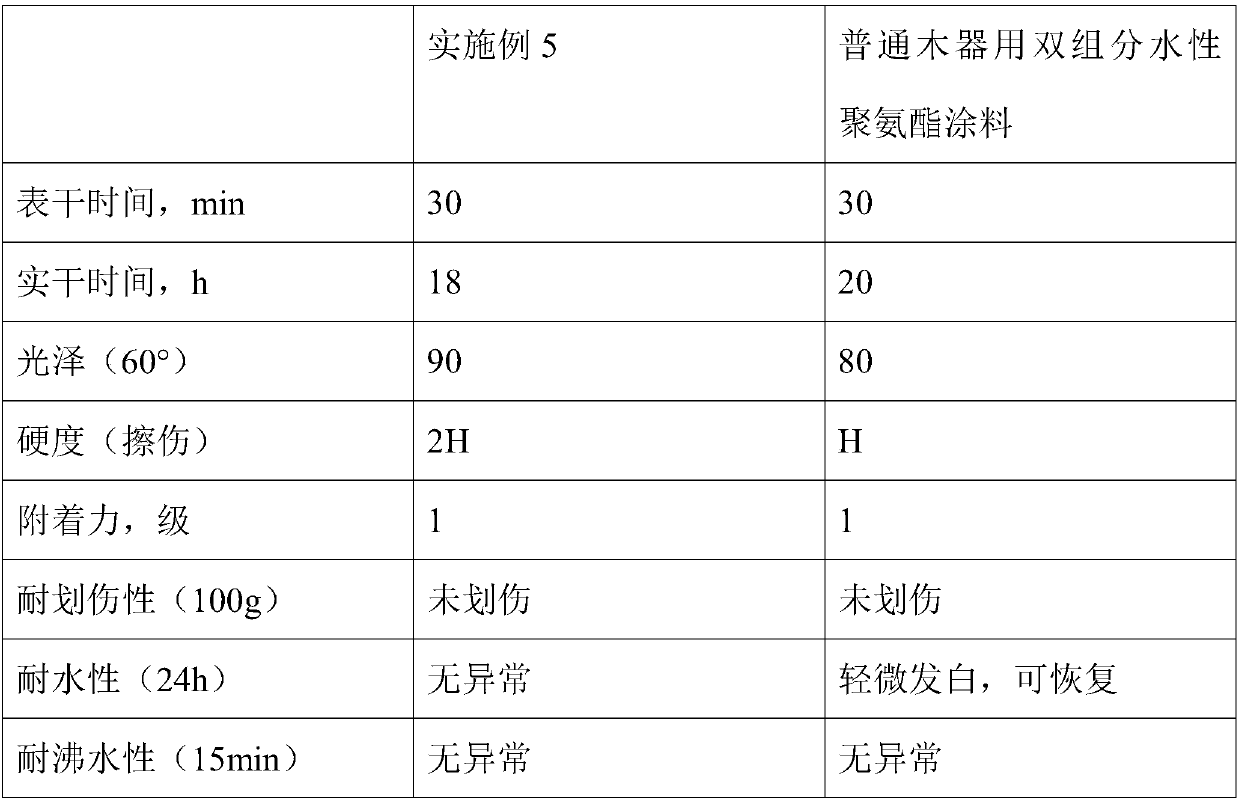

Examples

Embodiment 1

[0017] A two-component water-based polyurethane coating for wood, comprising: component a and component b, the weight ratio of component a and component b is 7:3;

[0018] The raw materials of component a include: 100kg of water-based polyurethane dispersion, 120kg of water-based alkyd resin, 30kg of low hydroxyl value acrylic emulsion, 10kg of degraded polyethylene glycol microspheres, 1kg of white carbon black, 1kg of zinc phosphate, 2kg of epoxy soybean oil, Disproportionated rosin 4kg, wetting agent 1kg, defoamer 2kg, leveling agent 1kg, thickener 2kg, deionized water 50kg.

[0019] The degraded polyethylene glycol microspheres are prepared by the following process: 80kg of polyethylene glycol 6000 is irradiated and degraded, the irradiation dose is 0.43MGy, exhausted and degassed, crushed to a particle size of 23-46μm, and 12kg of oxidized polyethylene wax is added Stir for 4 minutes at a stirring speed of 900r / min, then add 4kg of aluminum nitrate, 8kg of boric acid, and...

Embodiment 2

[0022] A two-component water-based polyurethane coating for wood, comprising: component a and component b, the weight ratio of component a and component b is 9:1;

[0023] The raw materials of component a include: water-based polyurethane dispersion 140kg, water-based alkyd resin 80kg, low hydroxyl value acrylic emulsion 60kg, degraded polyethylene glycol microspheres 4kg, white carbon black 3kg, zinc phosphate 0.2kg, epoxy soybean oil 8kg , Disproportionated rosin 1kg, wetting agent 2kg, defoamer 1kg, leveling agent 2kg, thickener 1kg, deionized water 100kg.

[0024] The degraded polyethylene glycol microspheres are prepared by the following process: 40kg of polyethylene glycol 6000 is irradiated and degraded, the irradiation dose is 0.47MGy, exhausted and degassed, crushed to a particle size of 23-46μm, and 2kg of oxidized polyethylene wax is added Stir for 8 minutes at a stirring speed of 500r / min, then add 10kg of aluminum nitrate, 3kg of boric acid, and 200kg of water and...

Embodiment 3

[0027] A two-component water-based polyurethane coating for wood, comprising: component a and component b, the weight ratio of component a and component b is 7.5:2.5;

[0028] The raw materials of component a include: water-based polyurethane dispersion 110kg, water-based alkyd resin 110kg, low hydroxyl value acrylic emulsion 40kg, degraded polyethylene glycol microspheres 8kg, white carbon black 1.5kg, zinc phosphate 0.8kg, epoxy soybean oil 4kg, disproportionated rosin 3kg, wetting agent 1.3kg, defoamer 1.7kg, leveling agent 1.4kg, thickener 1.6kg, deionized water 60kg.

[0029] The degraded polyethylene glycol microspheres are prepared by the following process: 70kg of polyethylene glycol 6000 is irradiated and degraded, the irradiation dose is 0.44MGy, exhausted and degassed, crushed to a particle size of 23-46μm, and 10kg of oxidized polyethylene wax is added Stir for 5 minutes at a stirring speed of 800r / min, then add 6kg of aluminum nitrate, 6kg of boric acid, and 160kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com