Sea urchin-type Prussian blue-palladium core-shell structure loaded nitrogen-doped graphene nanocomposites and its prepared electrodes and applications

A technology of nitrogen-doped graphene and nanocomposite materials is applied in the fields of material preparation and electrochemical analysis, which can solve the problems of low sensitivity and high detection limit, and achieve the effects of high sensitivity, low detection limit and strong anti-interference performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

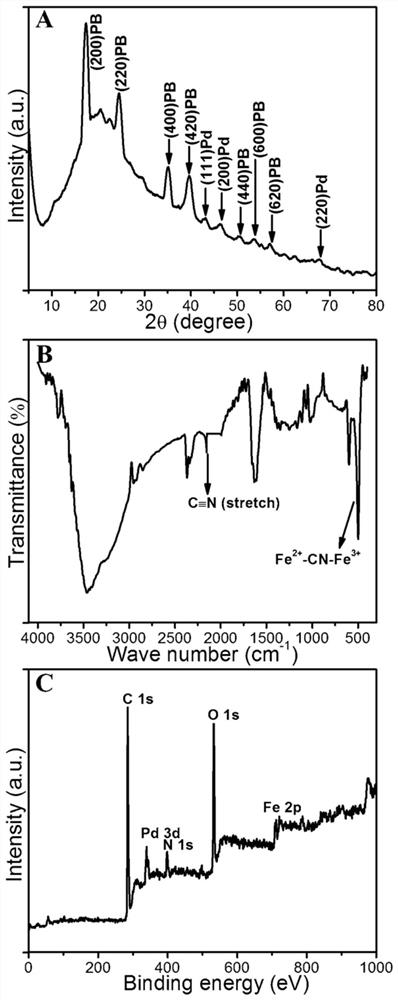

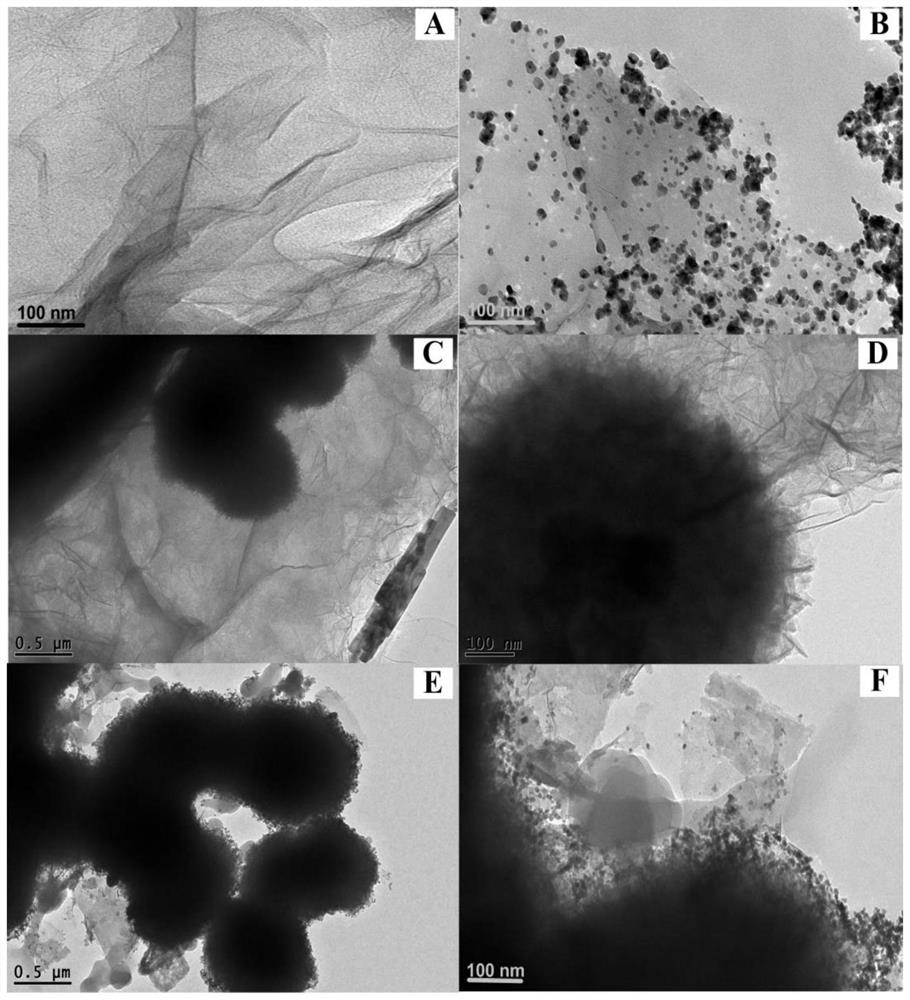

[0044] Example 1 Preparation of sea urchin type Prussian blue-palladium core-shell structure loaded nitrogen-doped graphene nanocomposite

[0045] S11. Add 0.016g K 3 Fe(CN) 6 Add it to a mixed solution consisting of 2.5mL concentrated hydrochloric acid, 2.5mL deionized water and 12.5 mL DMF, and magnetically stir to dissolve;

[0046] S12. Put the above solution into a hydrothermal reaction kettle and place it in an oven at 80°C for 24 hours, then let it stand for 12 hours and centrifuge, wash and dry to obtain Prussian blue;

[0047] S13. Take 2 mg of Prussian blue and add it to 2 mg of water, after ultrasonic dispersion, add 2 mL of PdCl dropwise within 30 min under magnetic stirring 2 solution (1mg / mL) and NaBH 4 solution (1mg / mL); then stand still for 1h and then centrifuge and wash to obtain the sea urchin-type Prussian blue-palladium core-shell structure material;

[0048] S14. Take the prepared Prussian blue-palladium core-shell structure material and disperse it i...

Embodiment 2

[0051] Example 2 Preparation of sea urchin-type Prussian blue-palladium core-shell structure loaded nitrogen-doped graphene nanocomposite modified electrode

[0052] S21. Take a glassy carbon electrode with a diameter of 3 mm, firstly grind it on the aluminum powder with a particle size of 0.3 μm for 8 minutes, then grind it on the aluminum powder of 0.05 μm for 8 minutes, and then wash it ultrasonically with dilute nitric acid, acetone and deionized water respectively , to obtain a pretreated glassy carbon electrode after drying;

[0053] S22. The sea urchin-type Prussian blue-palladium core-shell structure-loaded nitrogen-doped graphene nanocomposite material described in embodiment 1 was dispersed with DMF ultrasonically for 10min to obtain a 1mg / mL dispersion;

[0054] S23. Take 6.0 μL of the dispersion liquid and add it dropwise on the surface of the pretreated glassy carbon electrode, and after drying, the sea urchin-type Prussian blue-palladium core-shell structure-supp...

Embodiment 3

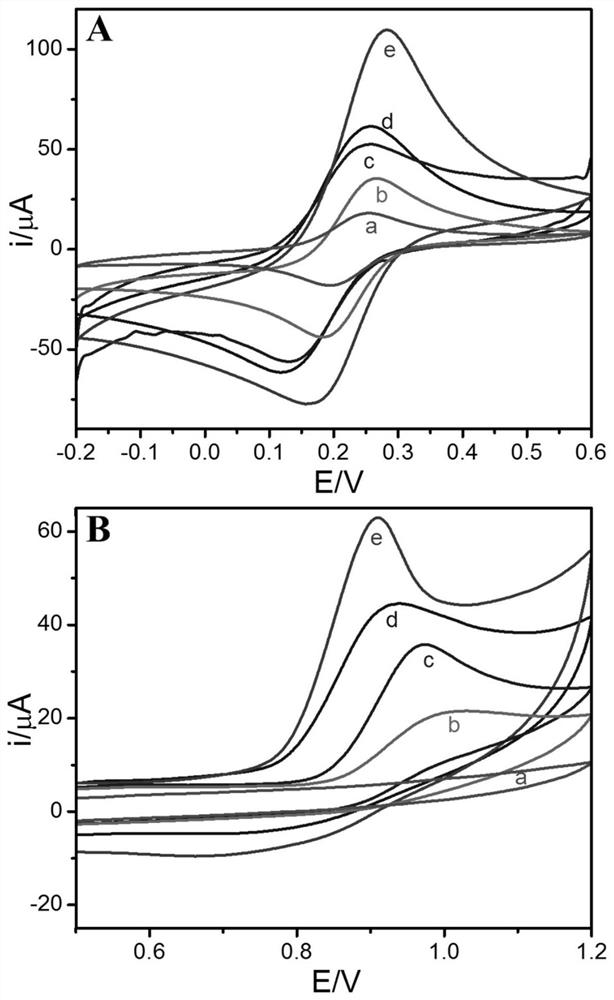

[0055] Example 3 Detection performance of sea urchin-type Prussian blue-palladium core-shell structure-loaded nitrogen-doped graphene composite membrane modified electrode

[0056] In this example, the sea urchin-type Prussian blue-palladium core-shell structure-supported nitrogen-doped graphene composite film modified electrode prepared in Example 2 was used as the experimental object, and it was combined with a platinum auxiliary electrode and an SCE reference electrode to form a three-electrode system. Connected to CHI660 electrochemical workstation (Shanghai Chenhua Instrument Co., Ltd.) for electrochemical performance testing.

[0057] (1) Characterization of electrochemical performance of different electrodes

[0058] with K 3 [Fe(CN) 6] as a probe to investigate the electrochemical performance of different modified electrodes by cyclic voltammetry. Fig. 3A shows that the probe ions on glassy carbon electrode (a), nitrogen-doped graphene modified glassy carbon electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com