Silicon nickel alloy-graphene electrode material and preparation method and application thereof

A graphene electrode and graphene technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of Si-based anode materials that cannot maintain structural integrity, electrode material pulverization, and cycle performance degradation. Excellent stability, low preparation cost, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of a silicon-nickel alloy-graphene electrode material

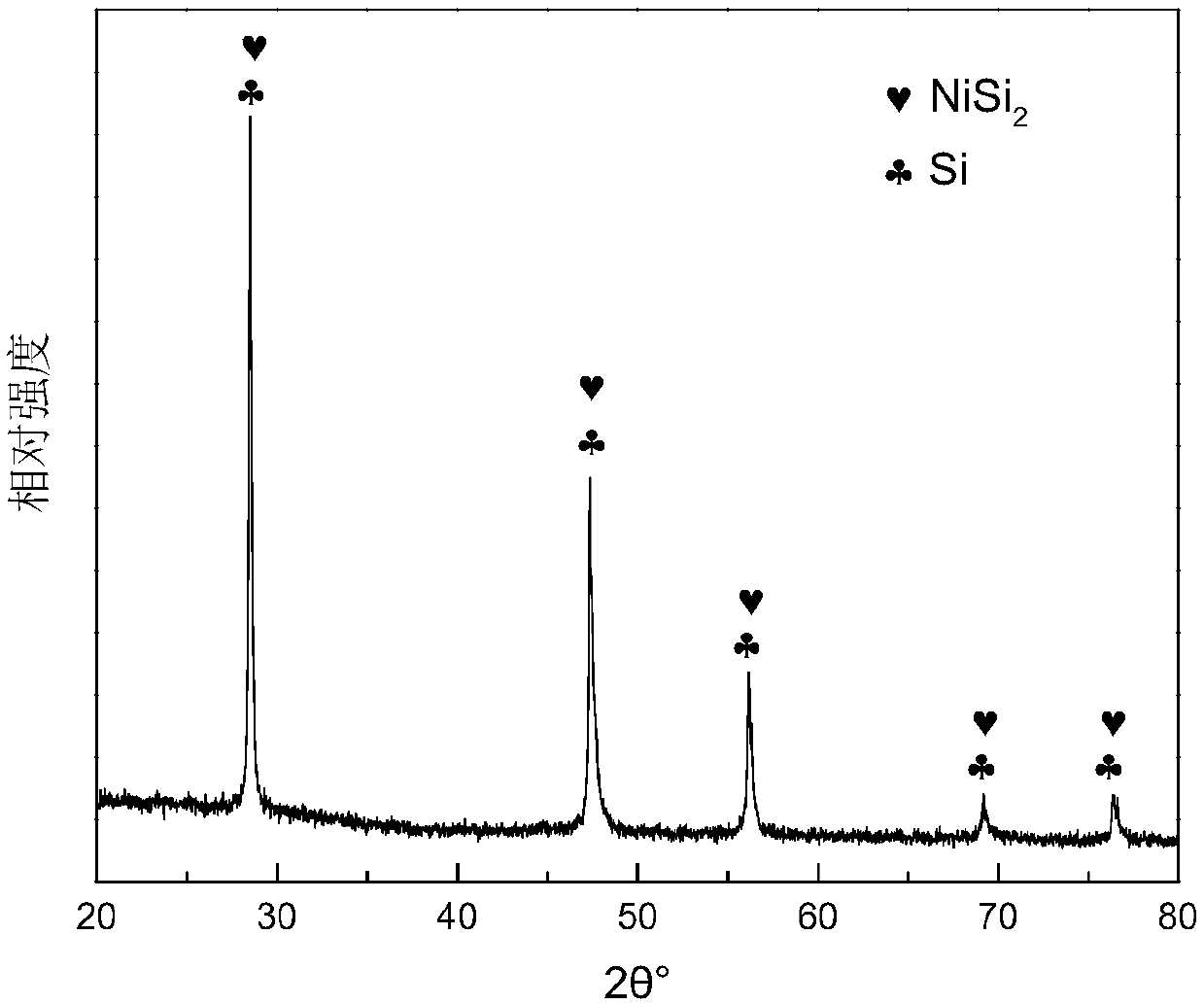

[0030] The commercial silicon powder and nickel powder are ball milled at a mass ratio of 6:1. The ball mill model is QM-3SP2, the ball milling time is 8 hours, the ball material ratio is 10:1, and the speed is 450r / min. Put the silicon-nickel mixture obtained by ball milling into a φ20mm mold and put it into a spark plasma sintering furnace, apply a pressure of 3MPa to both ends of the grinding tool, and vacuumize the furnace body, and then raise the temperature to 1000°C at a rate of 100°C / min. and keep it warm for 10 minutes, then cool to room temperature to obtain a silicon-nickel alloy block.

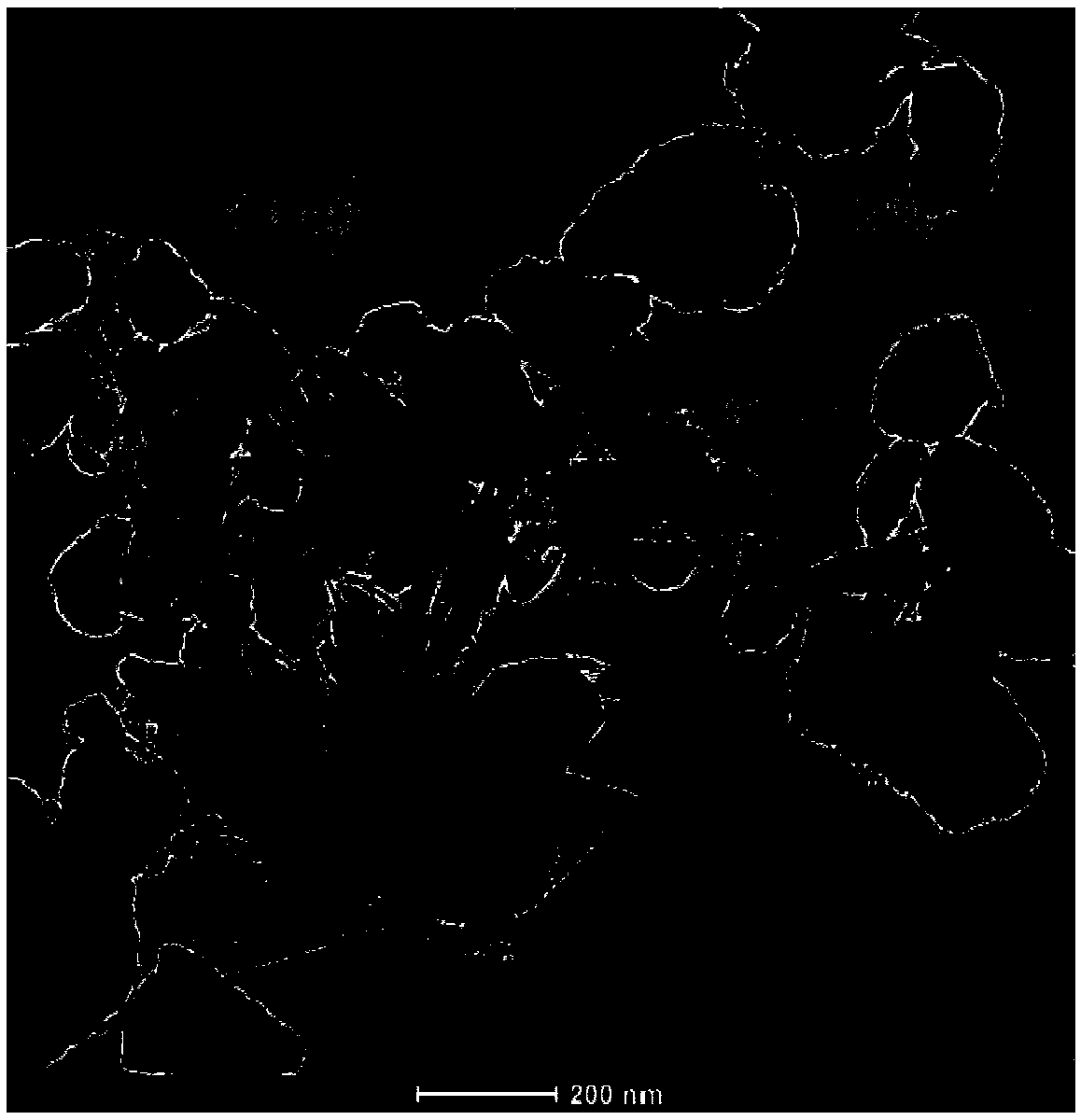

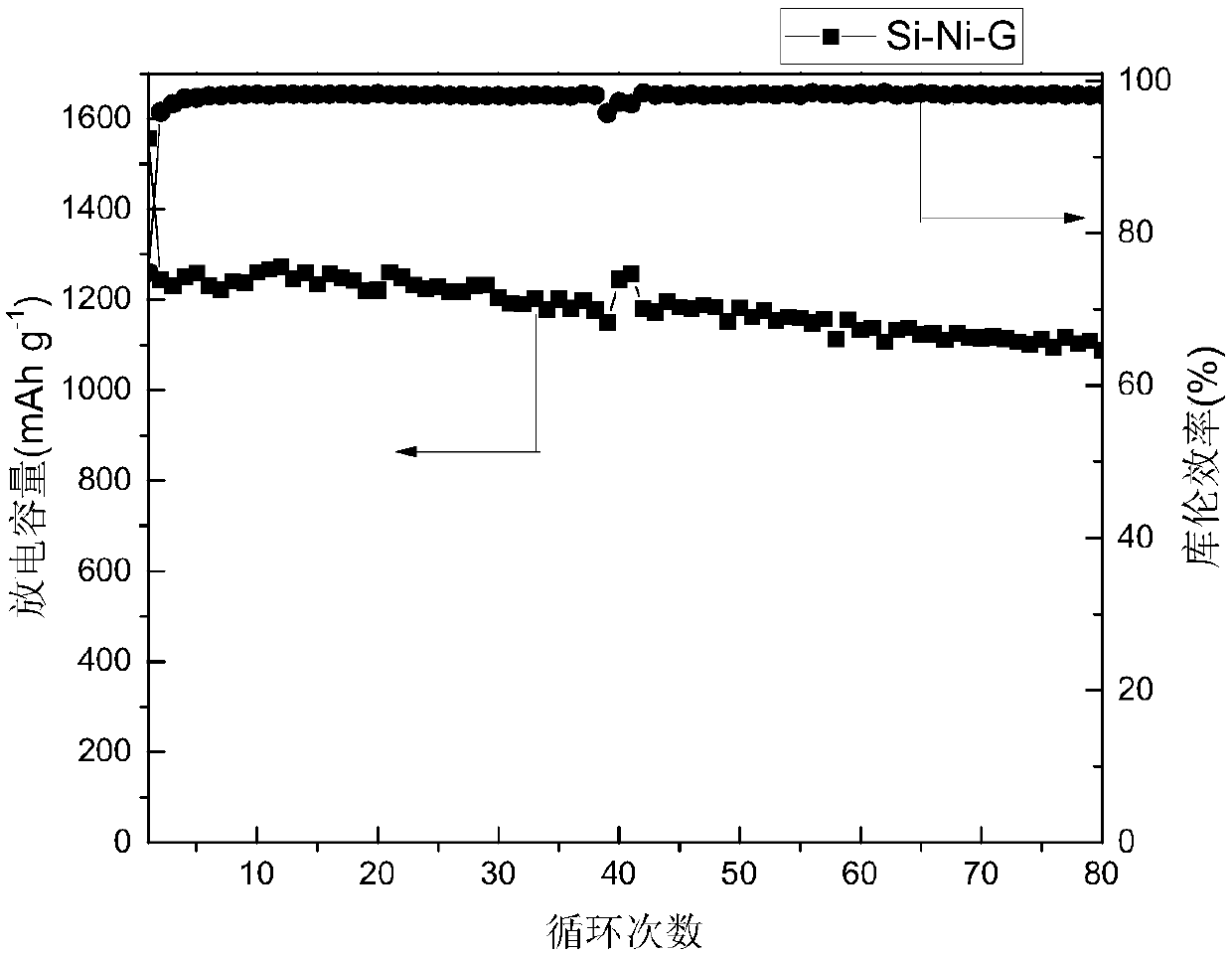

[0031] The obtained silicon-nickel block was ball-milled with a ball-to-material ratio of 40:1, a rotational speed of 450 r / min, and a ball-milling time of 3 hours to obtain silicon-nickel alloy powder. Then the silicon-nickel alloy powder and graphene powder were ball-milled and compounded, the mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com