Preparation of arachin-carboxymethyl chitosan glycosylation nanoparticles and application thereof

A technology of carboxymethyl chitosan and globulin, which is applied in the field of functional health food nanocapsules, can solve the problems of low bioavailability and unstable EGCG properties, and achieves improved grafting effect, excellent performance and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation of peanut globulin among the present invention adopts following method:

[0043]Take 15.0g peanut defatted powder, dissolve in 100mL, pH 8.0, 0.2mol / L phosphate buffer solution, stir with a magnetic stirrer for 2h, centrifuge at 4°C, 8000rpm for 30min, take the supernatant and add a certain amount of ammonium sulfate Make it reach 40% saturation, dissolve and stir for 2 hours, centrifuge for 30 minutes, discard the supernatant, redissolve the precipitate in 20 mL of deionized water, stir and dissolve evenly, dialyze for 24 hours, and freeze-dry to obtain peanut globulin powder. The protein content is about 72% as measured by elemental analyzer EA3000.

Embodiment 1

[0045] (1) Preparation of peanut globulin-carboxymethyl chitosan glycosylation product by wet method:

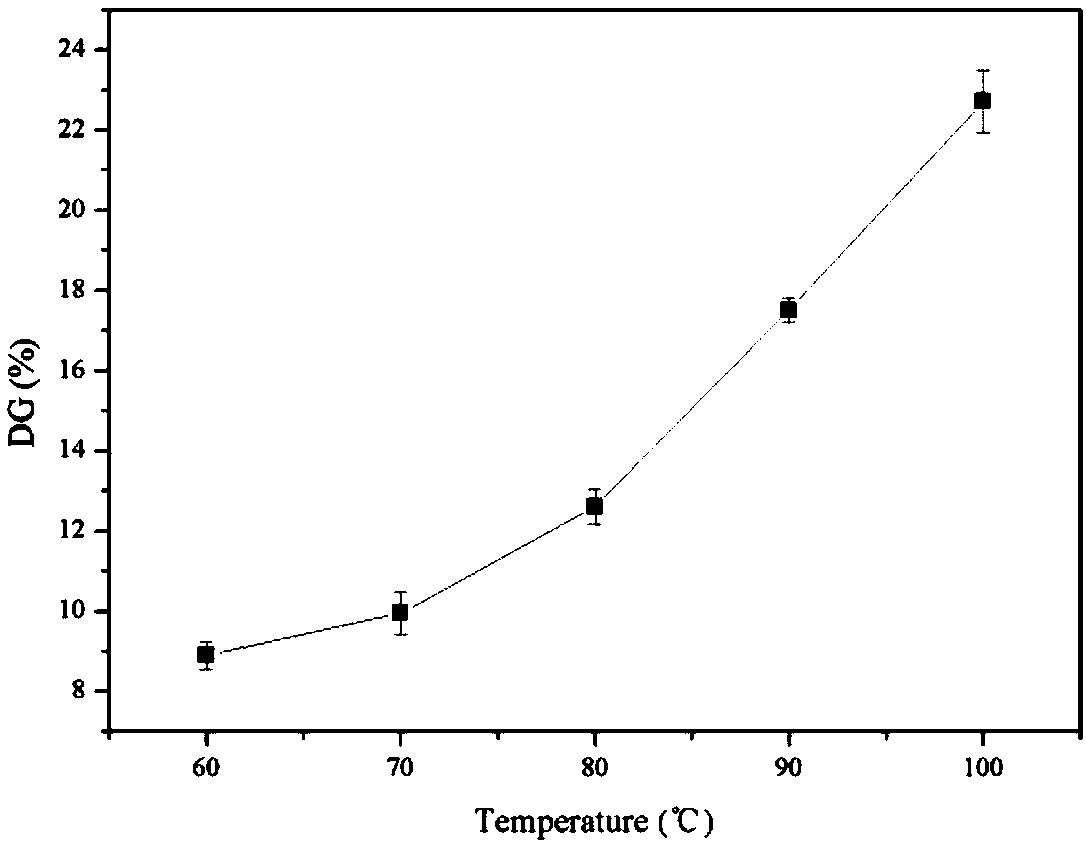

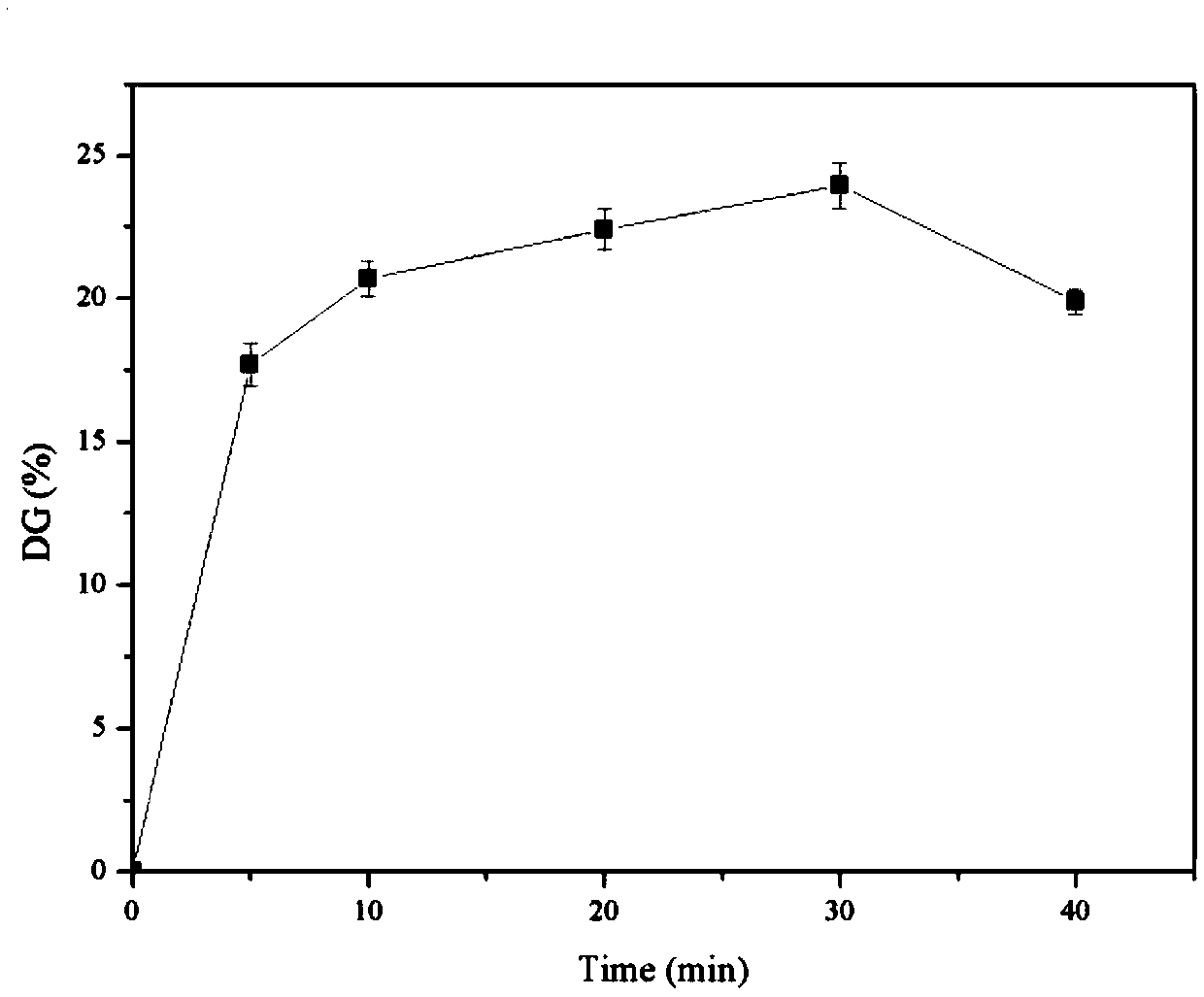

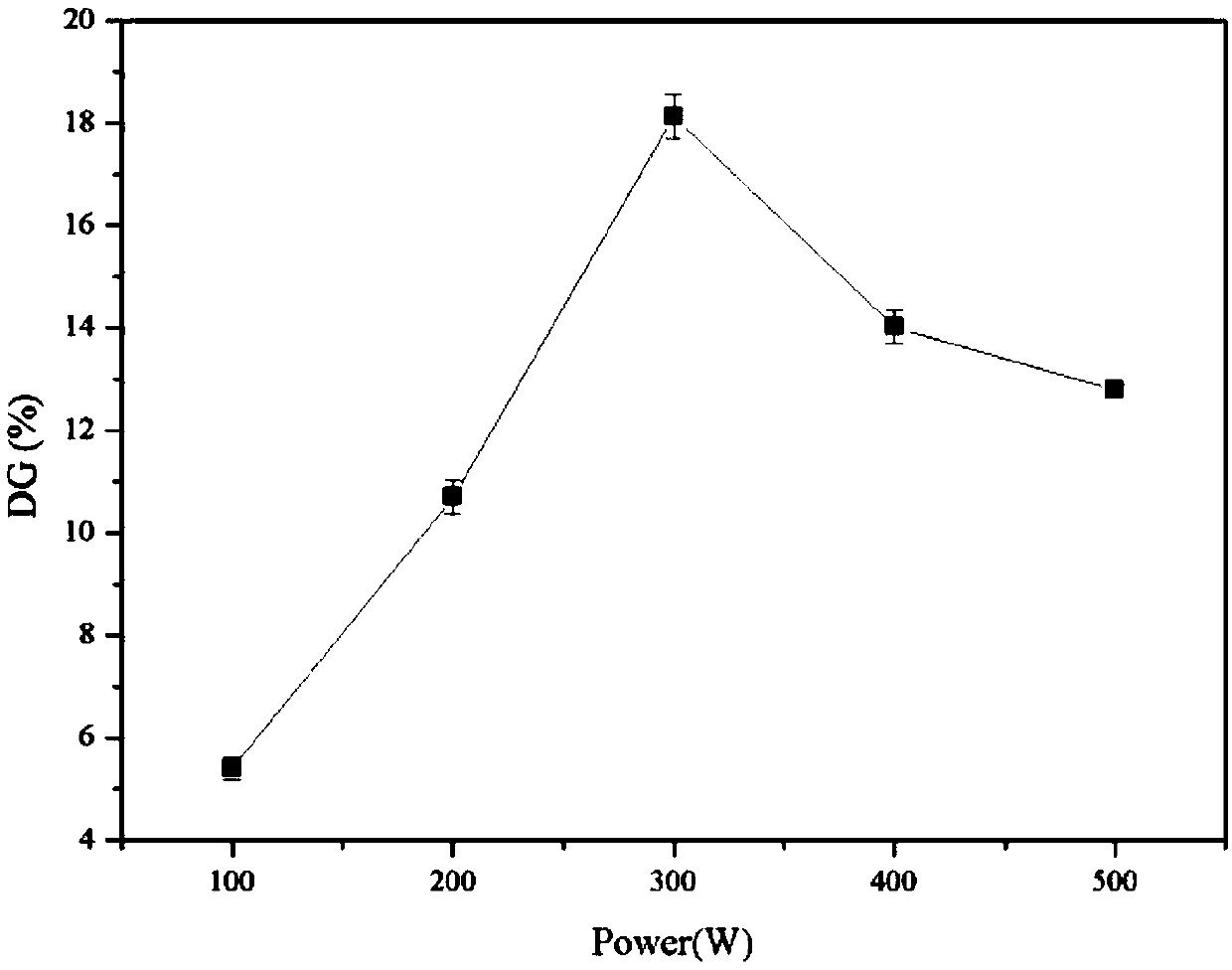

[0046] Dissolve carboxymethyl chitosan and protein with a mass ratio of 0.5:1 in a certain amount of phosphate buffer solution (0.2mol / L, pH 8.0), control the protein concentration to 1mg / mL, and put it into Microwave catalytic synthesizer, set the reaction power to 300W, the reaction temperature to 70°C, the reaction time to 10min, set the constant temperature mode to carry out microwave synthesis, and obtain the primary wet glycosylation product.

[0047] (2) dry method prepares peanut globulin-carboxymethyl chitosan copolymer:

[0048] The primary glycosylation product prepared in step (1) was freeze-dried for 48 hours, then ground into powder, placed in a reaction vessel containing saturated potassium bromide, and the reaction humidity was controlled at 79%, and the reaction temperature was 50°C; Reaction 7 After 2 days, the reaction was cooled to terminate the reaction...

Embodiment 2

[0050] (1) Preparation of peanut globulin-carboxymethyl chitosan glycosylation product by wet method:

[0051] Dissolve carboxymethyl chitosan and protein with a mass ratio of 1:1 in a certain amount of phosphate buffer solution (0.2mol / L, pH 8.0), control the protein concentration to 2mg / mL, and mix thoroughly with magnetic stirring Put it into a microwave catalytic synthesizer, set the reaction power to 400W, the reaction temperature to 80°C, and the reaction time to 20min, and set the temperature constant mode to carry out microwave synthesis to obtain the primary wet glycosylation product.

[0052] (2) dry method prepares peanut globulin-carboxymethyl chitosan copolymer:

[0053] The primary glycosylation product prepared in step (1) was freeze-dried for 45 hours, then ground into powder, placed in a reaction vessel containing saturated potassium bromide, and the reaction humidity was controlled at 70%, and the reaction temperature was 70°C; Reaction 4 After 2 days, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com