Preparation method for upconversionnanoparticles wrapped by mesoporous silica loading indocyanine green

A technology of mesoporous silica and nanoparticles, which is applied in the fields of biotechnology and medicine, can solve the problems of unstable photodegradation, limit the application of PDT tumor treatment, etc., and achieve obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

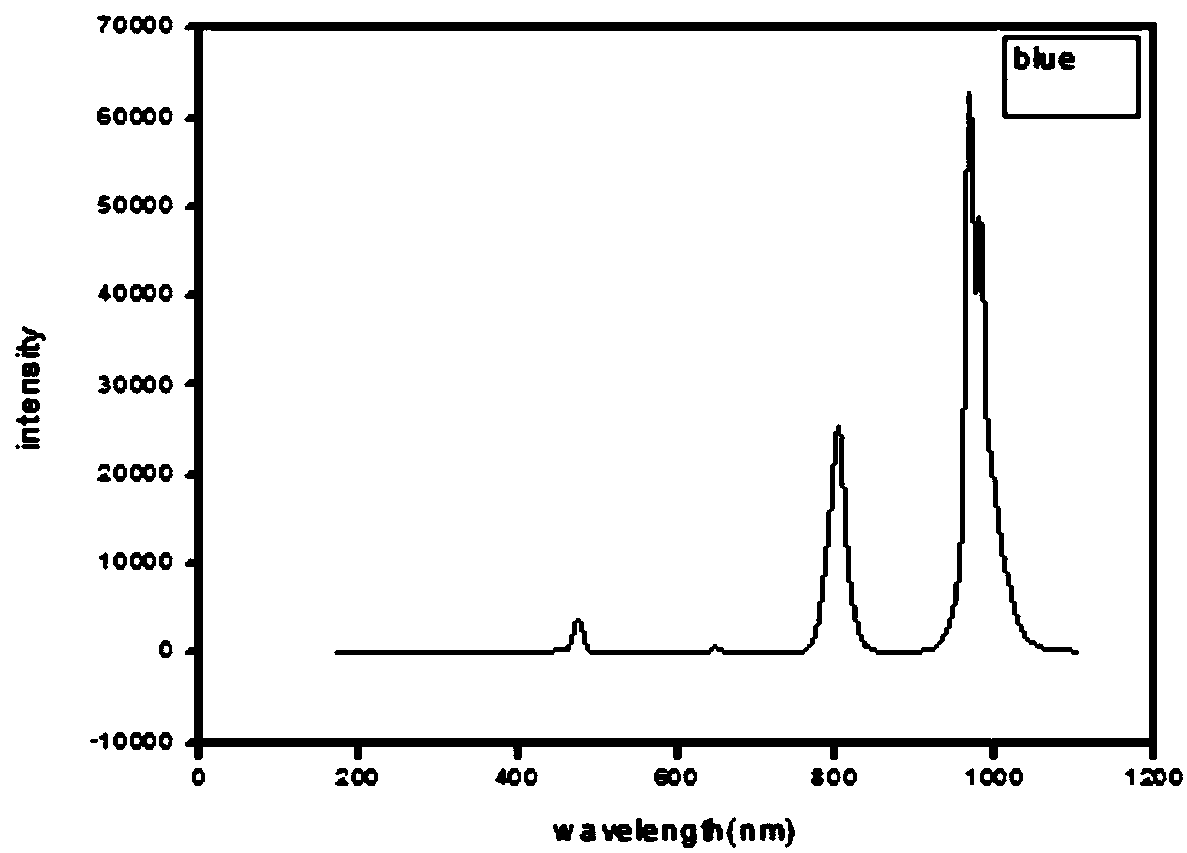

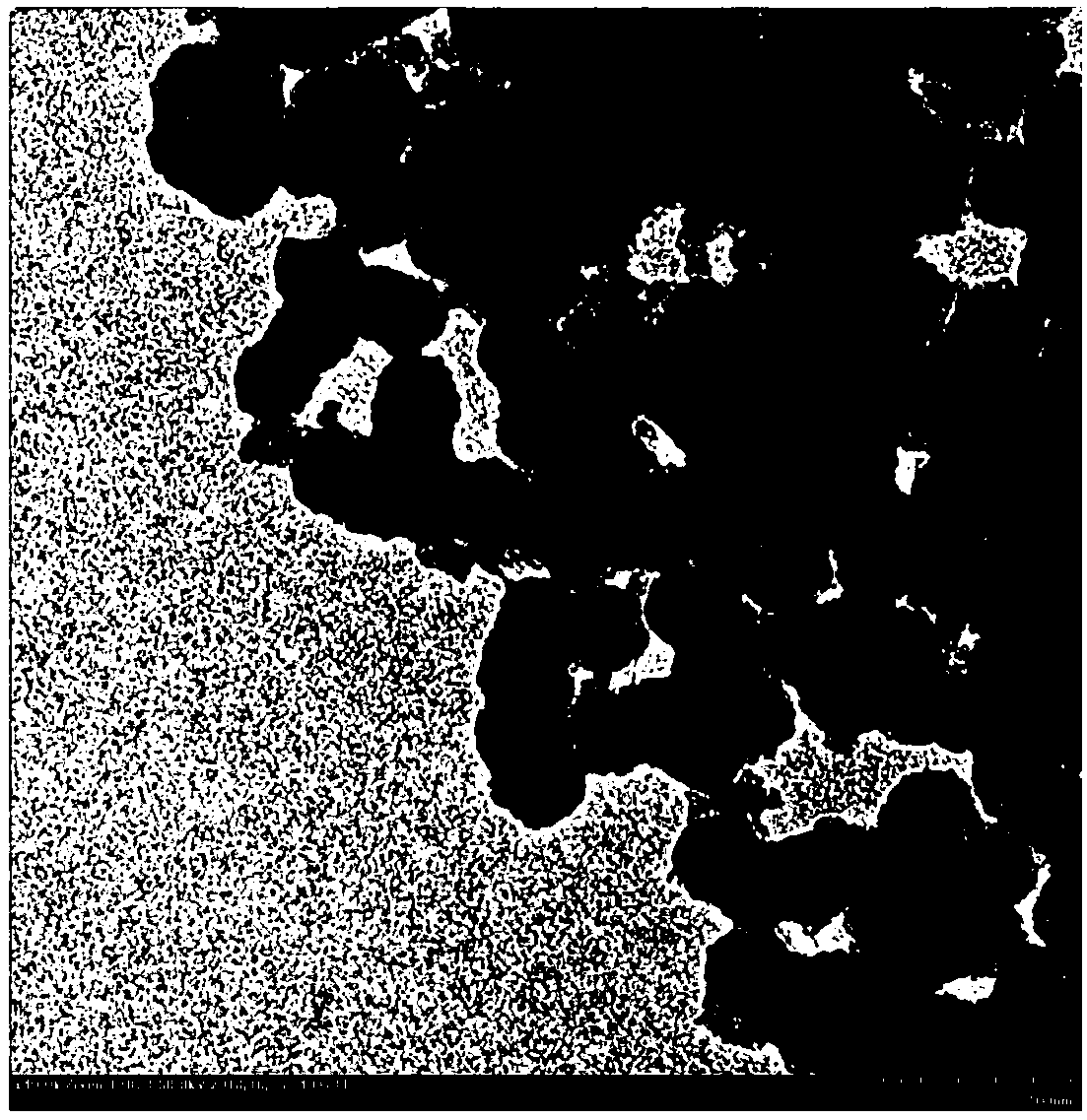

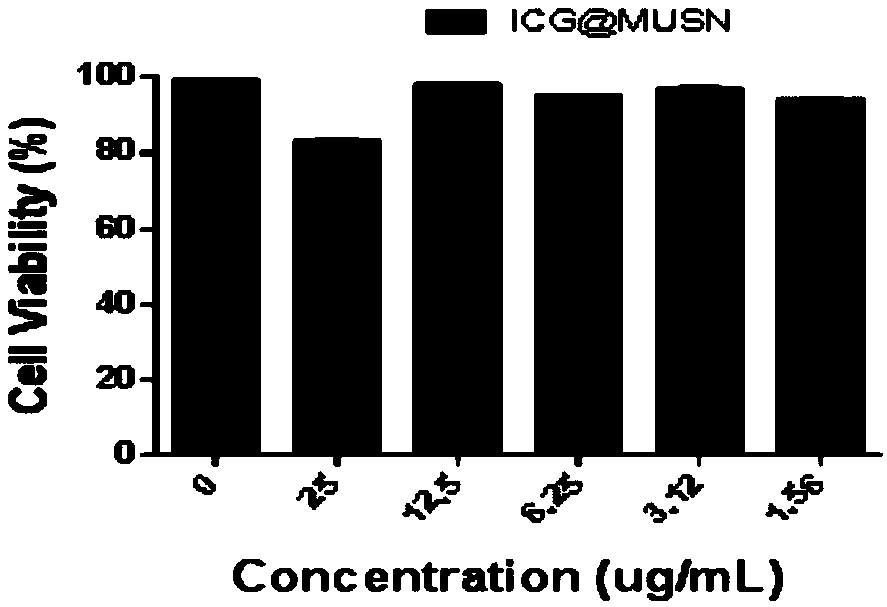

Embodiment 1

[0027] Mix the yttrium chloride hexahydrate, ytterbium chloride hexahydrate, and thulium chloride hexahydrate solutions in a volume ratio of 700:100:10, heat at 110°C for 15 minutes until it turns into a white powder, stop heating and rotate continuously, and lift Cool the flask to 50°C, add 2mL oleic acid and 10mL octadecene, heat up to 140°C, the color changes from milky white to yellow (about one hour), and cool down to the boiling point of methanol (64.7°C). Weigh 0.5M methanol solution of sodium fluoride, add it dropwise into a three-neck flask, raise the temperature to 110°C, and connect the gas circuit when there are no bubbles on the liquid surface. After evacuating for half an hour, pass nitrogen gas, raise the temperature to 260° C., and finish the reaction after one hour. Centrifuge with equal volume of ethanol, 8000 rpm for 10 min to collect the precipitate, add 20 mL of cyclohexane, centrifuge at 2000 rpm for 5 min, collect the supernatant, repeat the above steps ...

Embodiment 2

[0031]Mix the solutions of yttrium chloride hexahydrate, ytterbium chloride hexahydrate, and thulium chloride hexahydrate in a volume ratio of 800:200:40, mix well and heat at 120°C for 15 minutes until it turns into white powder, stop heating and keep rotating, lift the flask, Cool down to 50°C, add 10mL oleic acid and 40mL octadecene, raise the temperature to 180°C, the color changes from milky white to yellow (about one hour), cool down to the boiling point of methanol (64.7°C). Weigh 2.5mM sodium fluoride in methanol, add it dropwise into a three-neck flask, raise the temperature to 110°C, and connect the gas circuit when there are no bubbles on the liquid surface. After evacuating for half an hour, pass nitrogen gas, raise the temperature to 400°C, and finish the reaction after one hour. Centrifuge with equal volume of ethanol, 8000 rpm for 10 min to collect the precipitate, add 20 mL of cyclohexane, centrifuge at 2000 rpm for 5 min, collect the supernatant, repeat the ab...

Embodiment 3

[0035] Mix the solutions of yttrium chloride hexahydrate, ytterbium chloride hexahydrate, and thulium chloride hexahydrate evenly in a volume ratio of 780:200:20, heat at 110°C for 20 minutes until it turns into white powder, stop heating and keep rotating, lift the flask, Cool down to 50°C, add 6mL oleic acid and 15mL octadecene, raise the temperature to 150°C, the color changes from milky white to yellow (about one hour), cool down to the boiling point of methanol (64.7°C). Weigh 0.168g of sodium fluoride, dissolve it in 4mL of methanol, add it dropwise into a three-neck flask, raise the temperature to 110°C, and connect the gas line when there are no bubbles on the liquid surface. After evacuating for half an hour, pass nitrogen gas, raise the temperature to 300°C, and finish the reaction after one hour. Centrifuge with equal volume of ethanol, 8000 rpm for 10 min to collect the precipitate, add 20 mL of cyclohexane, centrifuge at 2000 rpm for 5 min, collect the supernatant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com