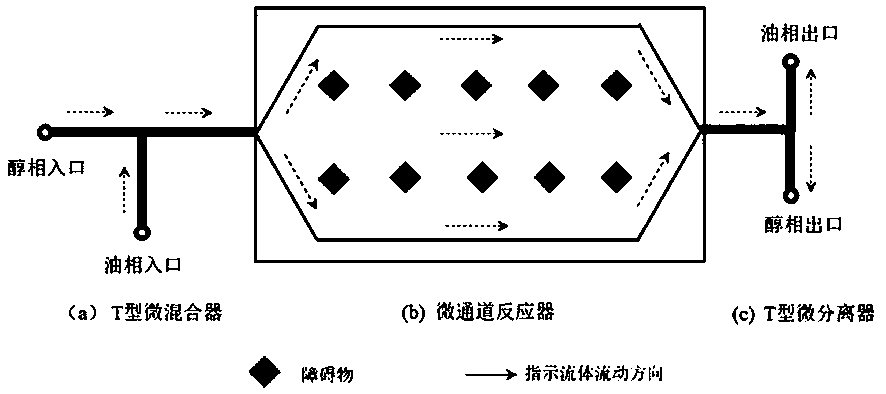

Method for synthesizing and separating biodiesel through catalyst-wall-loaded micro-reactor and micro-separator with interfacial property difference

A micro-separator, biodiesel technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, biofuels, etc., can solve the problems of catalyst environmental pollution, difficult post-processing, low conversion rate, etc., and achieve streamlined Production process, easy direct separation, high conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The plunger pump injected soybean oil and methanol into a micro-mixer with an inner diameter of 1 mm at 876 μl / min and 534 μl / min respectively, and then flowed to a wall-loaded [HSO 3 -pmim]HSO 4 The catalyst is in a microchannel reactor made of stainless steel, and the reaction time is 5 minutes. The reacted product will flow to the T-type micro-separator. The T-type micro-separator is composed of a liquid outlet pipe, an oil outlet pipe and an alcohol outlet pipe. The outlet ends of the liquid outlet pipe are respectively connected with an oil outlet pipe and an alcohol outlet pipe, and the reacted product flows into the outlet of the T-type micro-separator. The pipes flow out through the oil outlet pipe and the alcohol outlet pipe respectively to realize the separation of the product. The inner diameter of the T-type micro-separator is 3mm, the inner wall surface material of the alcohol outlet pipe in the T-type micro-separator is stainless steel, and the inner wal...

Embodiment 2

[0022]The plunger pump injects soybean oil and methanol into the micro-mixer with an inner diameter of 1 mm at 735 μl / min and 675 μl / min respectively, and then flows to the wall-loaded [HSO 3 -pmim]HSO 4 Catalyst In the microchannel reactor made of perfluoroethylene propylene, the reaction temperature is 90°C, the pressure is 0.6MPa, and the reaction time is 8min. The reacted product will flow to the T-type micro-separator. The catalyst wall-loading method and the T-type micro-separator are the same as in Example 1, and the following Examples 3-7 are also applicable. The final chromatographic analysis yield of biodiesel was 95.6%.

Embodiment 3

[0024] The plunger pump injects palm oil and methanol into the micro-mixer with an inner diameter of 1 mm at 876 μl / min and 534 μl / min respectively, and then flows to the wall-loaded [HSO 3 -bmim]HSO 4 In the microchannel reactor made of polyperfluoroethylene propylene, the reaction temperature is controlled at 120°C, the pressure is 0.8MPa, and the reaction time is 5min. The reacted product will flow to the T-shaped micro-separator. The final chromatographic analysis yield of biodiesel was 81.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com