Preparation method of bismuth oxychloride@bismuth oxybromide composite ultrathin nanosheet of three-dimensional structure

A bismuth oxychloride, three-dimensional structure technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of cumbersome operation process, limited improvement space, cumbersome preparation process, etc. Simple, avoid performance degradation, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

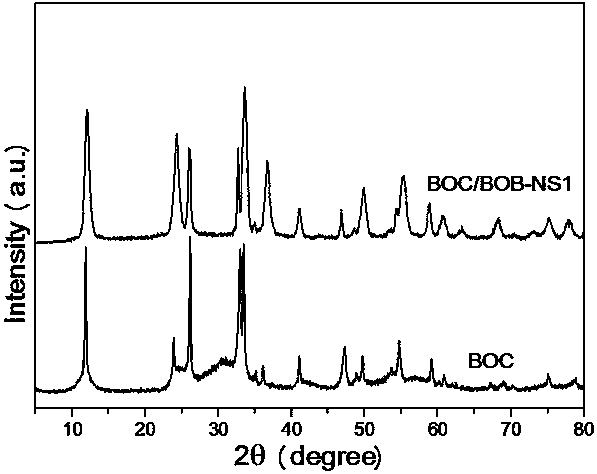

[0013] Dissolve 1mmol of bismuth nitrate pentahydrate and 1.2mmol of sodium dodecylbenzenesulfonate in 25mL of mannitol solution with a molar concentration of 0.1M, stir at room temperature until completely dissolved, and slowly add 5mL of saturated sodium chloride solution into the above solution, Continue to stir to obtain a white turbid solution. Transfer the obtained solution to a hydrothermal reaction kettle for hydrothermal reaction at 160°C for 3 hours. After cooling to room temperature, centrifuge and wash the white precipitate formed by the reaction with deionized water and ethanol respectively, and then vacuum at 60°C. Dry the product ultra-thin bismuth oxychloride nanosheets; then disperse 3g of the obtained ultra-thin bismuth oxychloride nanosheets into 200mL saturated potassium bromide solution, stir at 90°C for 24h and vacuum dry to obtain the three-dimensional structure of bismuth oxychloride@bromine Bismuth Oxide Composite Superbo Nanosheet BOC / BOB-NS1.

Embodiment 2

[0015] Dissolve 1mmol of bismuth nitrate pentahydrate and 1.2mmol of sodium dodecylbenzenesulfonate in 25mL of mannitol solution with a molar concentration of 0.1M, stir at room temperature until completely dissolved, and slowly add 5mL of saturated sodium chloride solution into the above solution, Continue to stir to obtain a white turbid solution. Transfer the obtained solution to a hydrothermal reaction kettle for hydrothermal reaction at 160°C for 3 hours. After cooling to room temperature, centrifuge and wash the white precipitate formed by the reaction with deionized water and ethanol respectively, and then vacuum at 60°C. Dry the product ultra-thin bismuth oxychloride nanosheets; then disperse 3g of the obtained ultra-thin bismuth oxychloride nanosheets into 300mL saturated potassium bromide solution, stir at 90°C for 24h and vacuum dry to obtain the three-dimensional structure of bismuth oxychloride@bromine Bismuth Oxide Composite Superbo Nanosheet BOC / BOB-NS2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com