Tourmaline inner wall coating and preparation method thereof

A technology of interior wall coatings and raw materials, applied in the field of coatings, can solve problems such as adverse environmental effects, and achieve the effects of enhancing human immunity, regulating breathing, and inhibiting fungal infections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

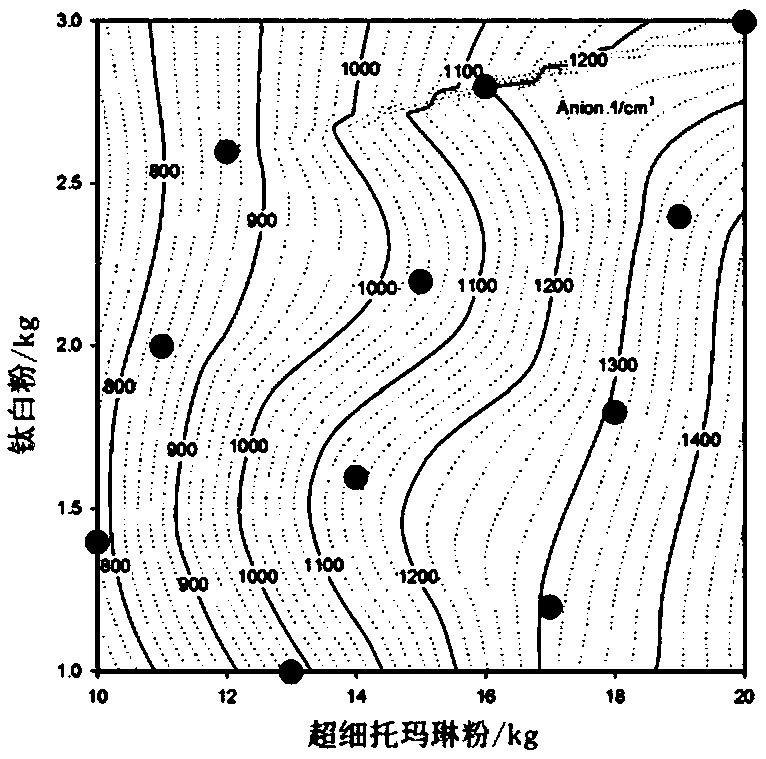

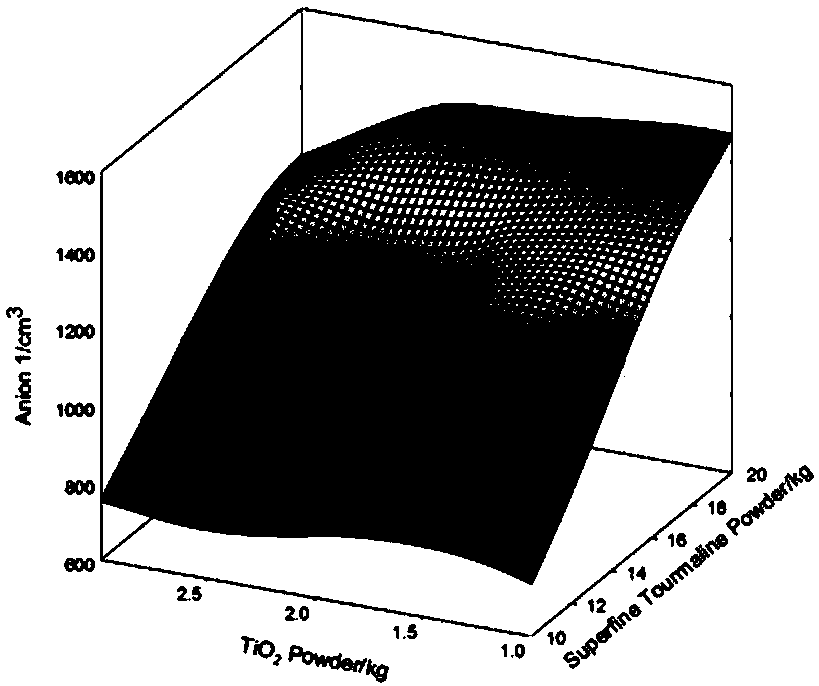

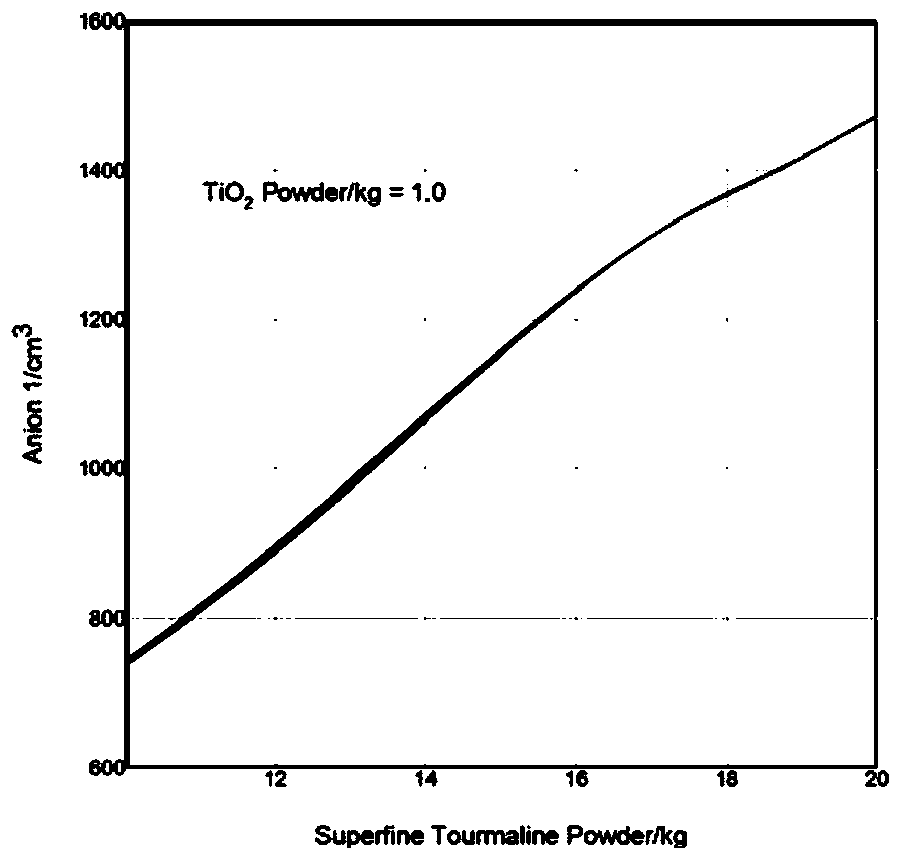

Image

Examples

Embodiment 1

[0057] A tourmaline interior wall paint, including the following materials: 800 mesh superfine tourmaline powder 10.00kg; titanium dioxide 1.40kg; lithopone 5.60kg; light calcium carbonate 16.00kg; bentonite 8.00kg; dispersant 0.22kg; adhesive 41.22kg. The adhesive includes the following raw materials by weight: 6.00 kg of polyvinyl alcohol aqueous solution; 2.10 kg of propylene glycol; 0.50 kg of hydrochloric acid; 1.40 kg of urea; 3.20 kg of sodium water glass and 35.00 kg of water.

[0058] The preparation method of the adhesive is:

[0059] (a) Mix the formula amount of polyvinyl alcohol solution, propylene glycol, hydrochloric acid, and 1 / 2 volume of water, stir at 300r / min for 5-10min;

[0060] (b) Mix the formula amount of urea and sodium water glass, add the remaining volume of water, and use a colloid mill for crushing and grinding for 5-10 minutes;

[0061] (c) Mix the materials obtained in step (a) and step (b), and use a high-speed shearing machine to shear and mix for 5-...

Embodiment 2

[0068] A tourmaline interior wall paint, including the following raw materials: 800 mesh superfine tourmaline powder 11.00kg; titanium dioxide 2.00kg; lithopone 7.60kg; light calcium carbonate 16.00kg; bentonite 6.00kg; dispersant 0.22kg; adhesive 42.82kg. The adhesive includes the following raw materials in weight: 6.00 kg of polyvinyl alcohol aqueous solution; 2.10 kg of propylene glycol; 0.50 kg of hydrochloric acid; 1.40 kg of urea; 3.20 kg of sodium water glass; 35.00 kg of water.

[0069] The preparation method is the same as in Example 1, and the negative ion generation capacity is: 839 pcs / cm 3 .

Embodiment 3

[0071] A tourmaline interior wall paint, including raw materials of the following weights: 800 mesh ultrafine tourmaline powder 2.00kg; titanium dioxide 2.60kg; lithopone 5.20kg; light calcium carbonate 16kg; bentonite 9.50kg; dispersant 0.22 kg; 45.52kg of adhesive. The adhesive includes raw materials of the following weights: 6.00 kg of polyvinyl alcohol aqueous solution; 2.10 kg of propylene glycol; 0.50 kg of hydrochloric acid; 1.40 kg of urea; 3.20 kg of sodium water glass and 35.00 kg of water.

[0072] The preparation method is the same as in Example 1, and the negative ion generation capacity is: 867 pcs / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com