Antiflaming impacting resistance automobile coating material

A coating material and impact-resistant technology, applied in coatings, polyether coatings, epoxy resin coatings, etc., can solve the problems of lower profit margins, lower competitiveness, paint performance, and environmental protection requirements, and achieve low cost , Enhanced bending strength, improved heat dissipation and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of coating materials:

[0026] (1) Heat 10kg of polyethylene glycol to 75°C to dissolve it, heat and stir for 5 minutes, then add 5kg of modified graphene, 2kg of accelerator TMTD, 1kg of aluminum alloy powder, and 1kg of anti-aging agent SP to continue heat preservation and stirring for 10 minutes, then add 0.5kg diglycerin dioleate is sent into the colloid mill, and reacted for 1h to obtain the mixed colloid;

[0027] (2) Preheat the internal mixer to 75°C, then add 40kg modified epoxy resin, 35kg melamine formaldehyde resin and stir for 30min at a stirring speed of 220rpm, then heat up to 85°C, add 10kg resin alloy polyphenylene ether, step 1 Continue to stir the mixed colloid for 1 hour, let it stand for 10 minutes, cool down to 65° C. and continue to stir for 0.5 hour, cool down and discharge to obtain the coating material.

[0028] Preparation of modified epoxy resin: Add 30kg EPDM rubber into absolute ethanol, heat to reflux state, keep stirring for ...

Embodiment 2

[0031] Preparation of coating materials:

[0032] (1) Heat 10kg of polyethylene glycol to 75°C to dissolve it, heat and stir for 5 minutes, then add 5kg of modified graphene, 2kg of accelerator TMTD, 1kg of aluminum alloy powder, and 1kg of anti-aging agent SP to continue heat preservation and stirring for 10 minutes, then add 0.5kg diglycerin dioleate is sent into the colloid mill, and reacted for 1h to obtain the mixed colloid;

[0033] (2) Preheat the internal mixer to 75°C, then add 45kg modified epoxy resin, 30kg melamine formaldehyde resin and stir for 30min at a stirring speed of 220rpm, then heat up to 85°C, add 12kg resin alloy polyphenylene ether, step 1 Continue to stir the mixed colloid for 1 hour, let it stand for 10 minutes, cool down to 65° C. and continue to stir for 0.5 hour, cool down and discharge to obtain the coating material.

[0034] Preparation of modified epoxy resin: Add 30kg EPDM rubber into absolute ethanol, heat to reflux state, keep stirring for ...

Embodiment 3

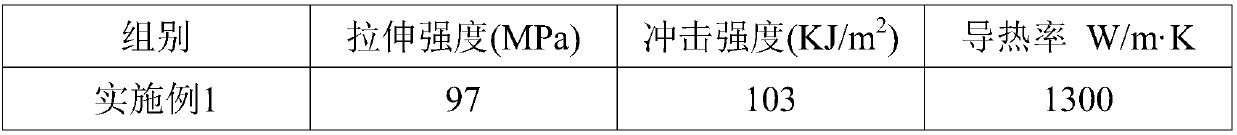

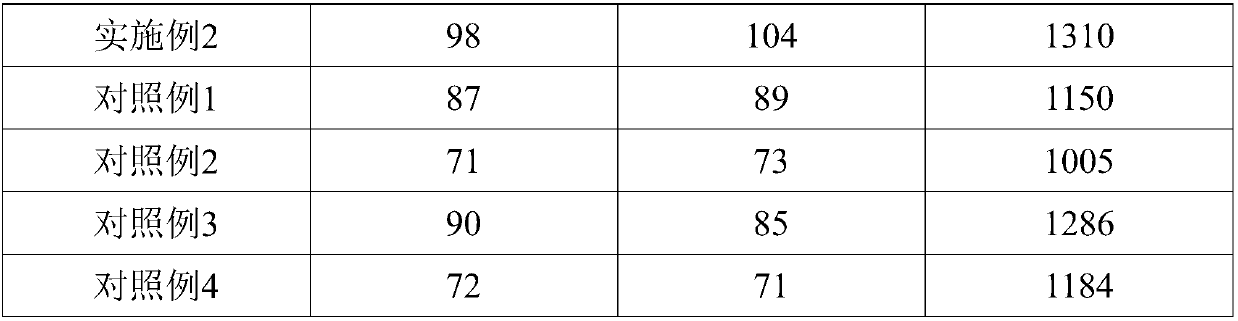

[0059] Based on Example 1, set the comparative example 1 that does not add acrylic acid, the comparative example 2 that does not modify epoxy resin, the comparative example 3 that does not add methyl p-hydroxybenzoate, the comparative example that does not modify graphene 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com