Inner wall paint for temperature-resistant corrosion-resistant chemical pump

A corrosion-resistant, chemical pump technology, applied in the field of coatings, can solve problems such as difficult and difficult paint films, and achieve the effects of not easy to fall off, not easy to form layers, and slow down penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

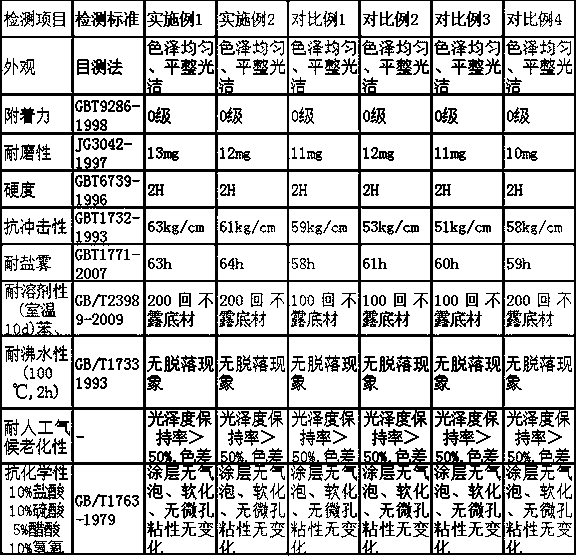

Examples

Embodiment 1

[0022] A heat-resistant and corrosion-resistant inner wall paint for chemical pumps is made of the following raw materials in parts by weight:

[0023] 12.6 parts of N-ethylperfluorooctanesulfonamidoethyl methacrylate, 63.5 parts of polyurethane acrylate macromer, 0.9 parts of N-hydroxyacrylamide, 1.5 parts of sodium dodecylbenzenesulfonate, methyl 33.5 parts of acrylate / perfluorooctyl ethyl acrylate copolymer, 0.8 parts of potassium persulfate, 65 parts of alkyd resin, 14.5 parts of strontium chromate, 6.6 parts of nano silicon dioxide, 13.5 parts of talc powder, 12.1 parts of andesite powder, 8.5 parts of diabase powder, 5.6 parts of carboxymethyl cellulose, 3.2 parts of vinyl alcohol monobutyl ether, 0.1 parts of sodium hexametaphosphate, 0.2 parts of ammonium phosphate, 0.3 parts of sodium pentachlorophenate, 27 parts of ethylene glycol, and 15 parts of water share. A heat-resistant and corrosion-resistant chemical pump inner wall coating, the preparation method of which ...

Embodiment 2

[0032] A heat-resistant and corrosion-resistant inner wall paint for chemical pumps is made of the following raw materials in parts by weight:

[0033]12.1 parts of N-ethylperfluorooctanesulfonamidoethyl methacrylate, 5.36 parts of polyurethane acrylate macromer, 1.1 parts of N-hydroxyacrylamide, 1.2 parts of sodium dodecylbenzenesulfonate, methyl 26.9 parts of acrylate / perfluorooctyl ethyl acrylate copolymer, 0.7 parts of potassium persulfate, 70 parts of alkyd resin, 13.5 parts of strontium chromate, 6.3 parts of nano silicon dioxide, 13.5 parts of talc powder, 12.1 parts of andesite powder, 8.9 parts of diabase powder, 4.9 parts of carboxymethyl cellulose, 2.8 parts of vinyl alcohol monobutyl ether, 0.2 parts of sodium hexametaphosphate, 0.2 parts of ammonium phosphate, 0.2 parts of sodium pentachlorophenate, 28 parts of ethylene glycol, and 125 parts of water share.

[0034] The preparation method of present embodiment coating is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com