Method for preparing functional protein polypeptide by using bionic method

A technology of functional protein and bionic method, which is applied in the direction of fermentation, etc., can solve the problems of insufficient degradation of antigenic protein content, insufficient digestion and absorption rate, and unstable quality of fermented soybean meal, so as to enhance the immunity of piglets and disease resistance, good social and economic benefits, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

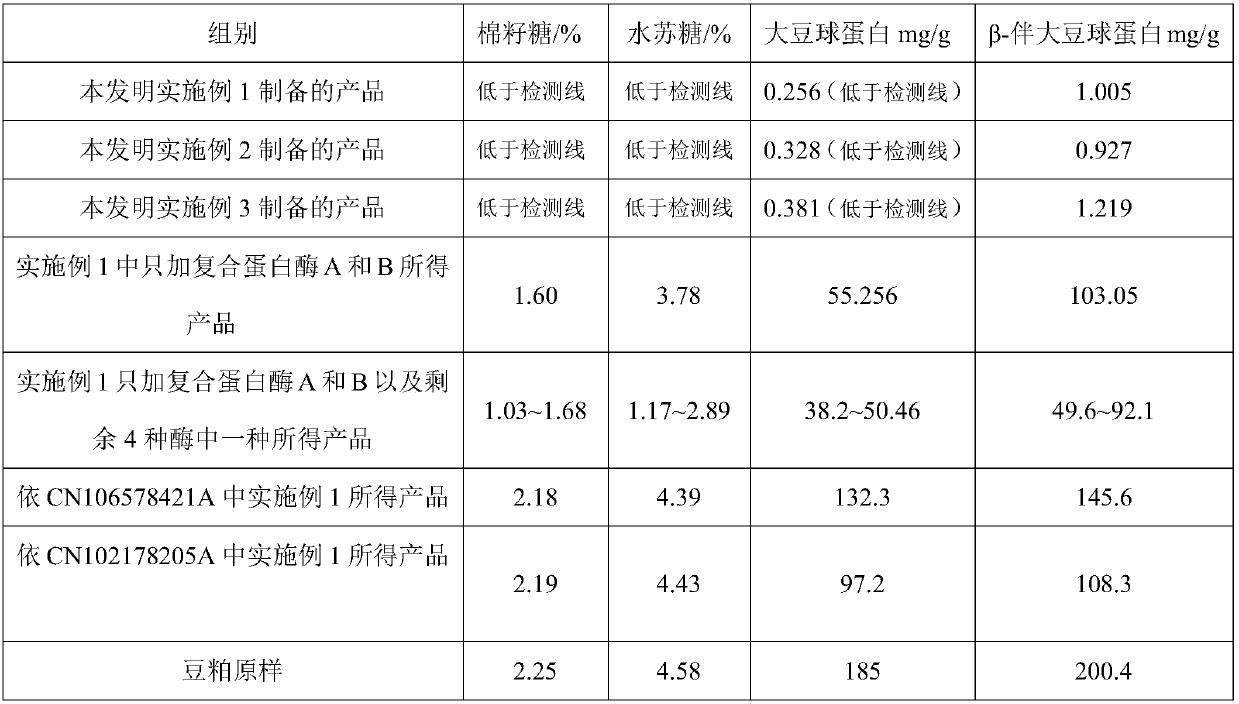

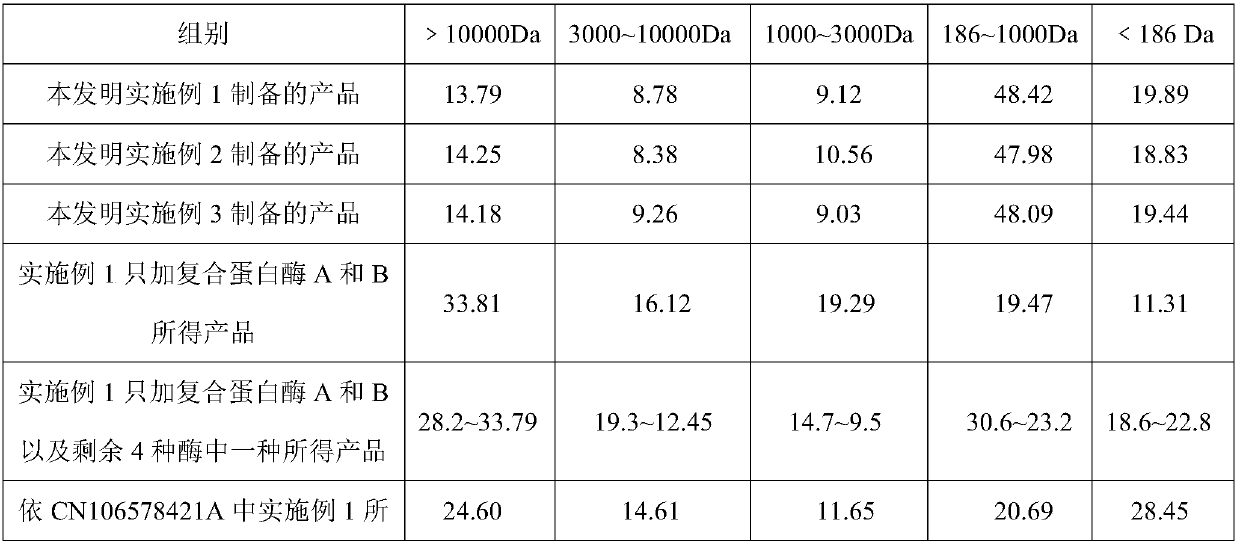

Embodiment 1

[0035] Get 500kg of defatted and dehulled soybean meal raw materials, pre-crumble it through a 60-mesh sieve, add water (the ratio of soybean meal raw material to water is 1:5) and stir evenly, and prepare a soybean meal mixture with a solid content of 15%; Value is adjusted to 3.5, add compound protease A (addition is 3% of plant protein solid matter amount, papain (addition is 1% of plant protein solid matter amount) and bromelain (addition amount is plant protein solid matter amount 1%) 1.5%), at 50°C, enzymatically hydrolyze for 6 hours, raise the temperature of the enzymatic hydrolyzate to 85°C, and inactivate the enzyme for 20 minutes to obtain a primary soybean meal enzymatic hydrolyzate; adjust the pH value of the primary soybean meal enzymatically hydrolyzate to 7, add compound protease B (addition is 3.5% of vegetable protein solid matter quality), lysine aminopeptidase (addition is 3% of vegetable protein solid matter quality) and carboxypeptidase (addition is 5% of ...

Embodiment 2

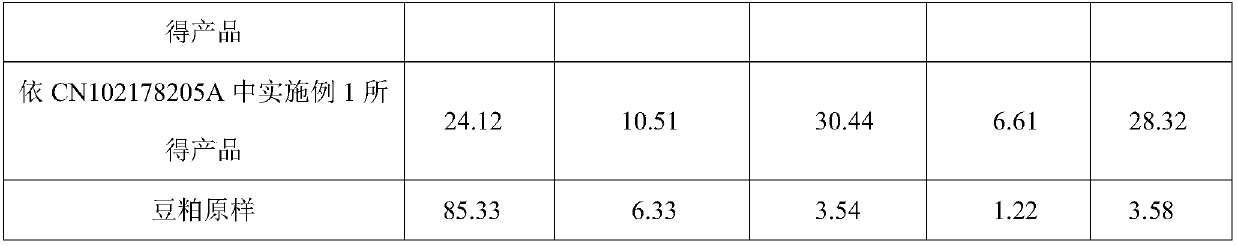

[0038] The difference between this embodiment and above-mentioned Example 1 is: 1) get 300kg rice protein raw material, rice protein and water weight ratio are 1:6, the amount of the compound protease A added is 2%, 0.05% papain and 0.5% % bromelain, at a pH of 4.5 and a temperature of 40°C, hydrolyze for 5 hours; 2) Enzyme inactivation at high temperature: after one enzymolysis, heat up to 70°C and maintain for 30 minutes; 3) The added complex protease B The amount is 5%, 0.6% lysine aminopeptidase and 2% carboxypeptidase, and the pH is 8, and the temperature is 45°C, and the enzymolysis is carried out for 6h; 4) the obtained secondary protein hydrolyzate is After homogenizing for 60 minutes, carry out high-speed centrifugal spray drying under the condition that the air inlet temperature is 200°C and the air outlet temperature is 70°C.

[0039] In this embodiment, the product quality is stable, and the content of active small molecule peptides (19% for those with a relative m...

Embodiment 3

[0041] The difference between this embodiment and above-mentioned embodiment 1 is: 1) get peeled soybean meal, cottonseed meal and rapeseed meal (1:1:1) raw material 150kg, raw material and water weight ratio are 1:7, the compound protease added The amount of A is 4%, 0.7% papain and 1% bromelain, and the pH is 5.5, and the temperature is 45°C, and the enzymolysis is carried out for 4 hours; ℃, maintained for 10 minutes; 3) the amount of compound protease B added was 7%, 1% lysine aminopeptidase and 4% carboxypeptidase, and the pH was 8 and the temperature was 60 ℃. Decompose for 3 hours; 4) After homogenizing the obtained secondary protein enzymatic hydrolyzate for 50 minutes, perform high-speed centrifugal spray drying under the condition that the air inlet temperature is 220°C and the air outlet temperature is 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com