Preparation process of high-corrosion-inhibition cleaning agent used for motor vehicle water circulation system

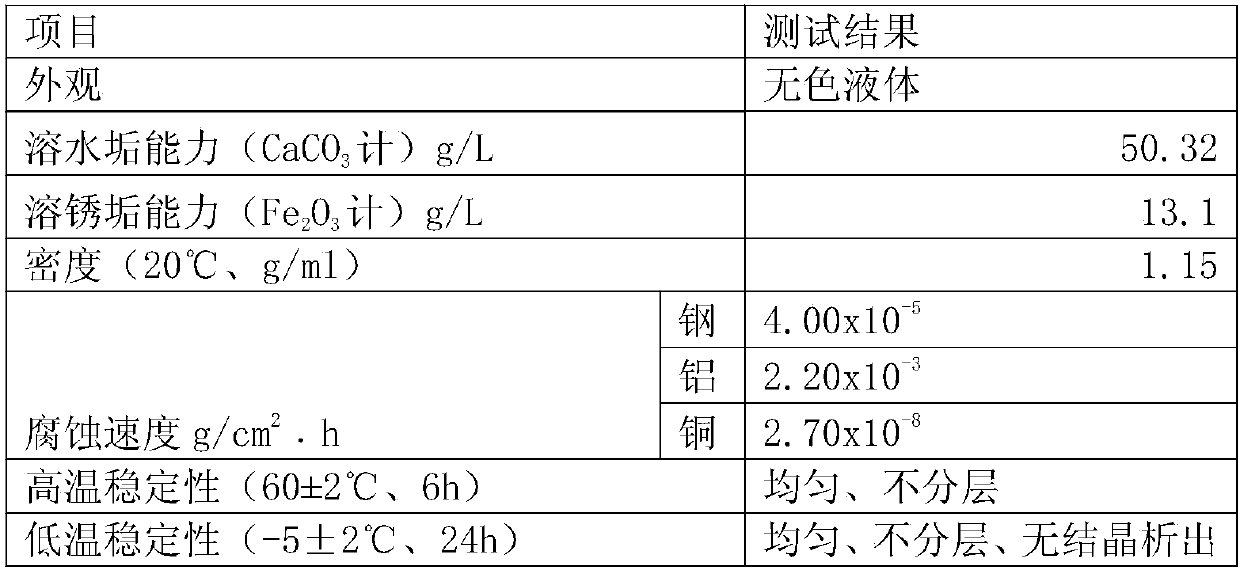

A preparation process and motor vehicle technology, applied in natural water treatment, non-polluted water treatment, complex/solubilizer treatment, etc., can solve problems such as equipment wear, heat exchange efficiency, and aluminum corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

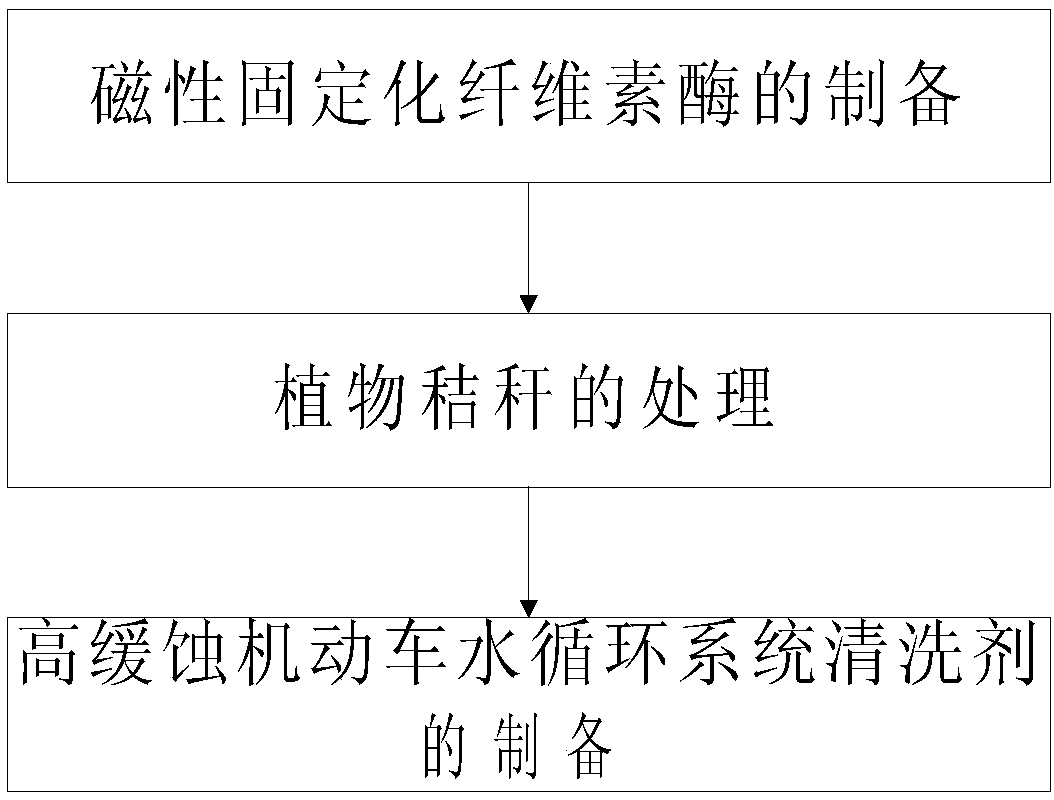

[0023] figure 1 It is a flowchart of a preparation process embodiment of a cleaning agent for a high-corrosion-inhibiting motor vehicle water circulation system of the present invention. As shown in the figure, the present invention provides a preparation process for a cleaning agent for a high-corrosion-inhibiting motor vehicle water circulation system, including the following steps :

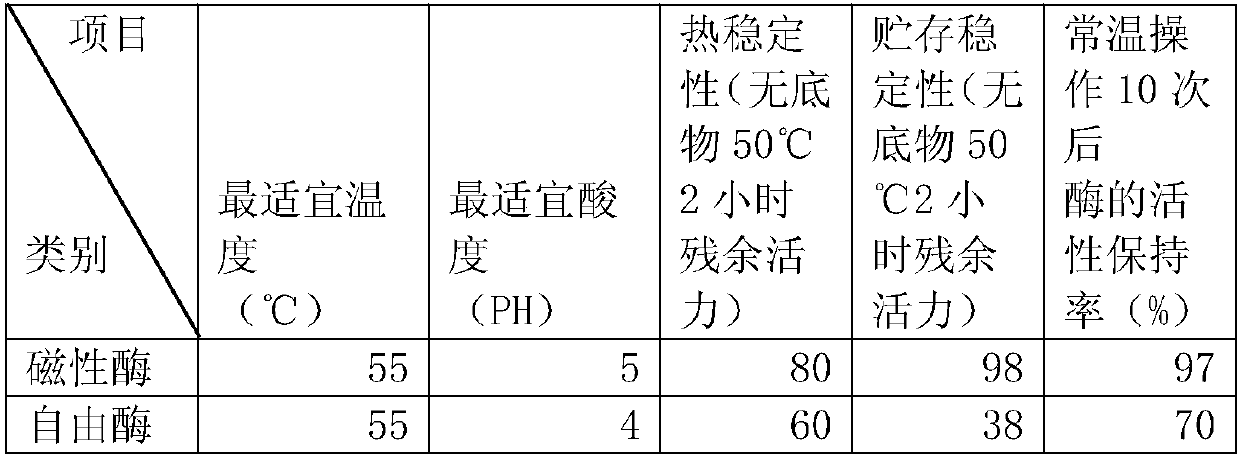

[0024] (1) Preparation of magnetically immobilized cellulase

[0025] Dissolve quantitative gelatin in double distilled water, add appropriate amount of ferrous chloride solution and hydrogen peroxide solution in turn, stir, add dropwise 3mol / L sodium hydroxide solution, protect with nitrogen, and react for several hours in a boiling water bath to obtain nano Grade magnetic gelatin particles;

[0026] Use the dialysis method to separate the nano-scale magnetic gelatin particles, weigh the quantitative nano-scale magnetic gelatin particles and add an appropriate amount of cellulase, shake at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com