Vinylon and preparation method thereof

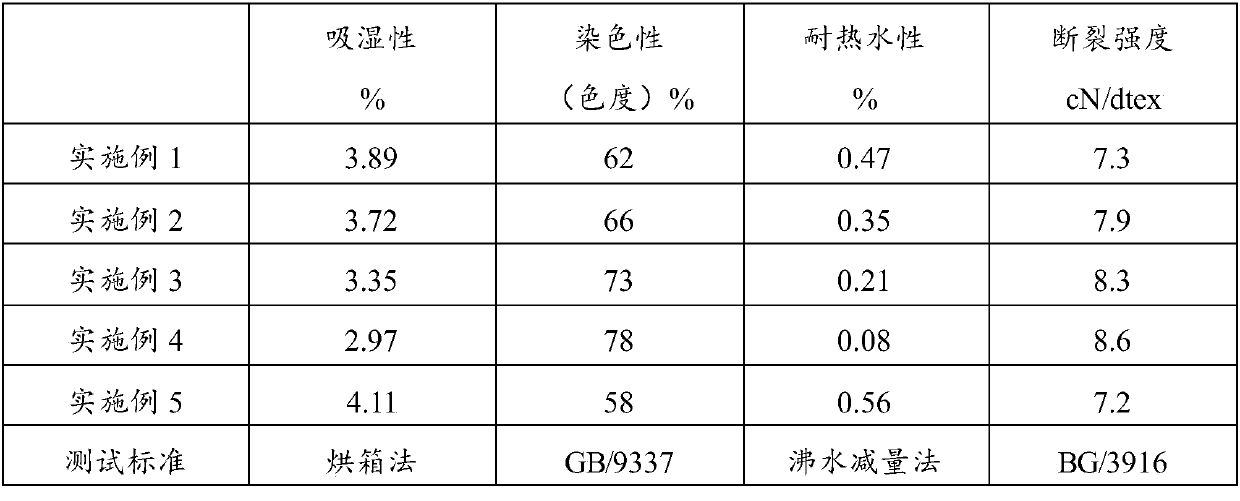

A technology of vinylon and polyvinyl alcohol solution, which is applied in the field of fiber materials, can solve the problems of high hygroscopicity of vinylon, difficulty in dyeing, poor hot water resistance and poor strength, and achieve the effects of low hygroscopicity, less pollution, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of vinylon, comprises the following steps:

[0031] a) mixing the polyvinyl alcohol solution with the modified solution to obtain a mixed emulsion;

[0032] b) irradiating the mixed emulsion obtained in step a) with an electron beam to obtain a composite emulsion;

[0033] c) spinning the composite emulsion obtained in step b) to obtain vinylon.

[0034] In the invention, the polyvinyl alcohol solution and the modified solution are firstly mixed to obtain a mixed emulsion. In the present invention, the polyvinyl alcohol solution is preferably an aqueous solution of polyvinyl alcohol cooked at 55°C to 99°C, more preferably an aqueous solution of polyvinyl alcohol cooked at 90°C. In the present invention, the source of the polyvinyl alcohol is not particularly limited, and commercially available products well known to those skilled in the art can be used. In a preferred embodiment of the present invention, the polyvin...

Embodiment 1

[0086] (1) Cook 1799 type polyvinyl alcohol at 90°C to obtain 100 kg of polyvinyl alcohol solution with a mass concentration of 15%, and cool to room temperature for subsequent use;

[0087] (2) mixing 1kg ethyl acrylate, 1kg n-butyl acrylate and 15kg mass concentration of 35% aqueous polyurethane emulsion to obtain a modified solution;

[0088] (3) Mix and stir the polyvinyl alcohol solution obtained in step (1) and the modified solution obtained in step (2) to obtain a mixed emulsion.

[0089] (4) controlling the thickness of the mixed emulsion obtained in step (3) at 2cm to 3cm, and carrying out electron beam irradiation 10kGy to obtain a composite emulsion;

[0090] (5) Heating the composite emulsion obtained in step (4) to 75° C., followed by spinning, coagulation and post-treatment in sequence to obtain vinylon.

Embodiment 2

[0092] (1) Cook 1799 type polyvinyl alcohol at 90°C to obtain 100 kg of polyvinyl alcohol solution with a mass concentration of 15%, and cool to room temperature for subsequent use;

[0093] (2) 1kg mass concentration is 35% silicone acrylic emulsion, 1kg n-butyl acrylate and 13kg mass concentration is 35% aqueous polyurethane emulsion mixing, obtains modified solution;

[0094] (3) Mix and stir the polyvinyl alcohol solution obtained in step (1) and the modified solution obtained in step (2) to obtain a mixed emulsion.

[0095] (4) Control the thickness of the mixed emulsion obtained in step (3) at 2cm to 3cm, and carry out electron beam irradiation 12kGy to obtain a composite emulsion;

[0096] (5) Heating the composite emulsion obtained in step (4) to 75° C., and then sequentially undergoing spinning, coagulation and subsequent treatment to obtain vinylon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com