A kind of fibrous mesh lithium-sulfur battery modified diaphragm and its preparation method and application

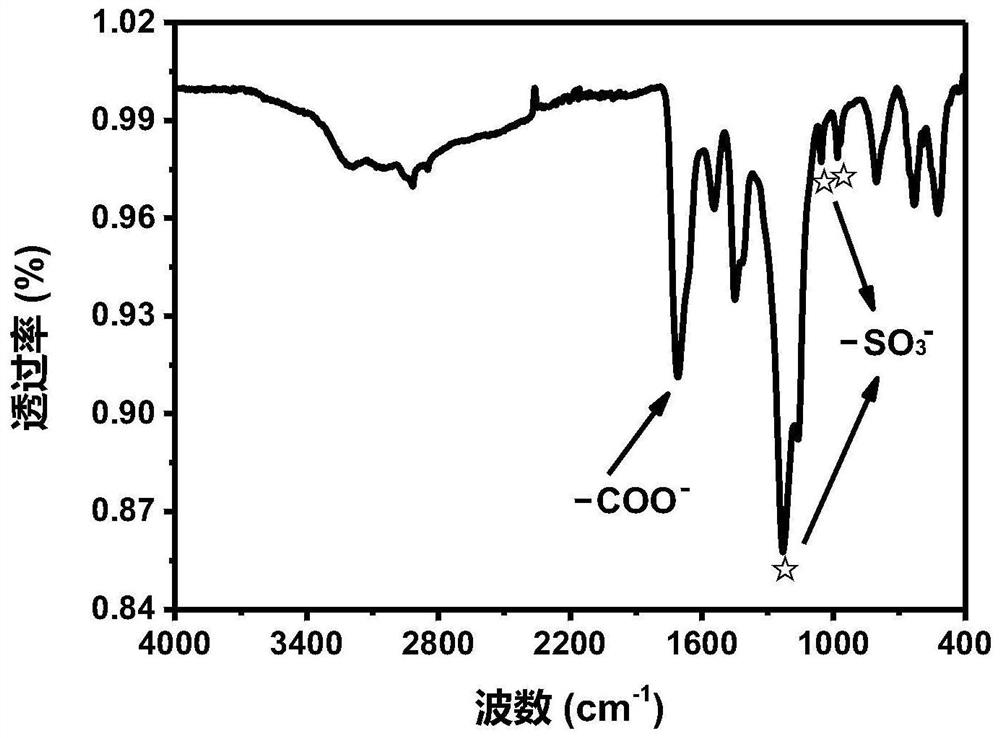

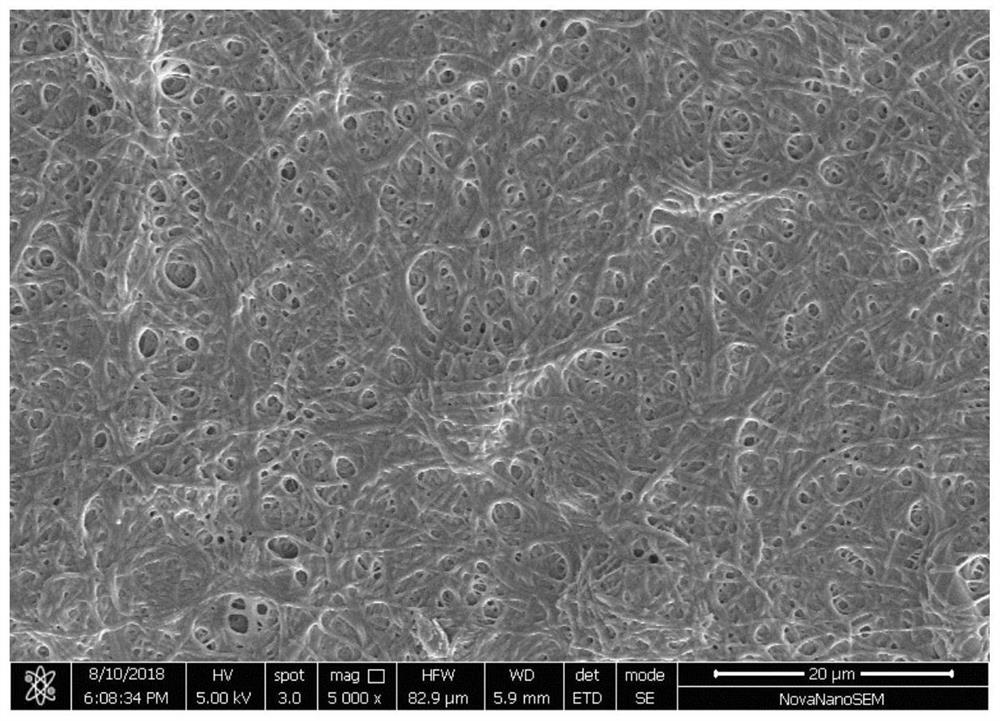

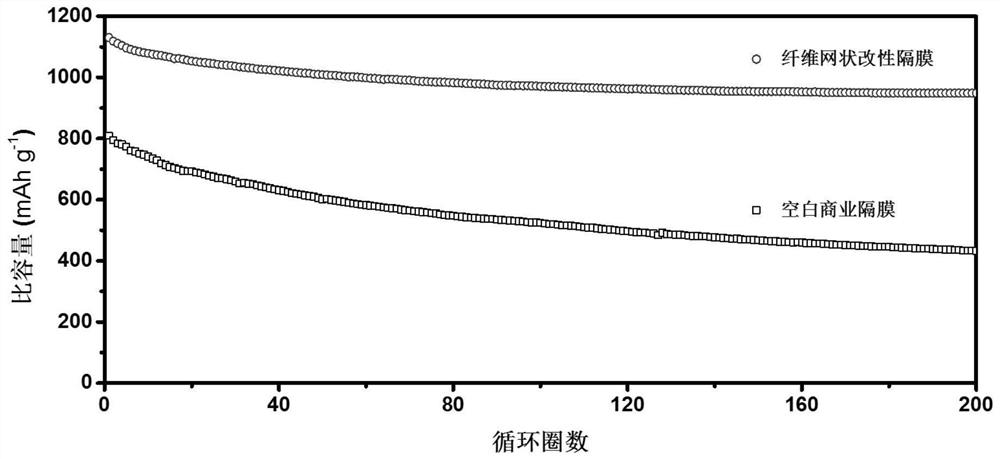

A lithium-sulfur battery, fiber mesh technology, applied in the field of lithium-sulfur battery modified separator and its preparation, can solve the problems of poor electrolyte wettability, rapid battery capacity decay, loss of active material, etc., and achieve excellent electrochemical performance, The effect of suppressing capacity fading and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of the modified diaphragm of the fiber mesh lithium-sulfur battery, the specific steps are as follows:

[0035] 1) Dissolve 0.5 g of polyacrylic acid powder in a mixed solvent of 9.5 g of water and n-propanol, the mass ratio of solvent water and n-propanol is 5:1, stir magnetically for 2 h, mix well, and the solution is transparent and colorless;

[0036] 2) Add 10 g of the commercial Nafion solution with a mass fraction of 5% to the polyacrylic acid solution in 1), stir magnetically for 2 hours and mix evenly, and the solution is transparent and colorless. After stopping the stirring, let it stand for 10 h to remove the air bubbles in the solution.

[0037] 3) The Nafion / polyacrylic acid mixed solution obtained in 2) was injected into a 5 ml medical syringe, placed in an electrospinning device, and spun at an injection speed of 0.3 ml / h and a voltage of 7 kV. A layer of commercial polyethylene diaphragm was wound on the roller receiver, the roller spee...

Embodiment 2

[0045] The preparation of the modified diaphragm of the fiber mesh lithium-sulfur battery, the steps are as follows:

[0046] 1) Dissolve 0.6 g of polyacrylic acid powder in a mixed solvent of 6.9 g of water and n-propanol, the ratio of solvent water and n-propanol is 4:1, stir magnetically for 3 h, mix well, and the solution is transparent and colorless;

[0047] 2) Add 8 g of the commercial Nafion solution with a mass fraction of 10% to the polyacrylic acid solution in 1), stir magnetically for 3 h and mix evenly, the solution is transparent and colorless; after stopping the stirring, let stand for 12 h to remove the bubbles in the solution;

[0048] 3) The Nafion / polyacrylic acid mixed solution obtained in 2) was injected into a 5 ml medical syringe, placed in an electrospinning device, and spun at an injection speed of 0.5 ml / h and a voltage of 8 kV. A layer of commercial polyethylene diaphragm was wound on the roller receiver, the roller speed was 50 r / min, and the distan...

Embodiment 3

[0053] The preparation of the modified diaphragm of the fiber mesh lithium-sulfur battery, the steps are as follows:

[0054] 1) Dissolve 0.6 g of polyacrylic acid powder in a mixed solvent of 4.4 g of water and n-propanol, the ratio of solvent water and n-propanol is 1:1, stir for 4 h under magnetic force, mix well, and the solution is transparent and colorless;

[0055] 2) Add 5 g of the commercial Nafion solution with a mass fraction of 5% to the polyacrylic acid solution in 1), stir magnetically for 6 h and mix evenly, the solution is transparent and colorless; after stopping the stirring, let stand for 15 h to remove the bubbles in the solution;

[0056] 3) The Nafion / polyacrylic acid mixed solution obtained in 2) was injected into a 5 ml medical syringe, placed in an electrospinning device, and spun at an injection speed of 0.5 ml / h and a voltage of 10 kV. A layer of commercial polypropylene diaphragm was wound on the roller receiver, the roller speed was 50 r / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com