A method for separately utilizing sulfur and calcium resources in gypsum

A gypsum and resource technology, applied in chemical instruments and methods, sulfur compounds, calcium/strontium/barium oxides/hydroxides, etc., can solve the problems of high heat consumption, high production cost, waste of resources, etc., and achieve separation efficiency High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific examples.

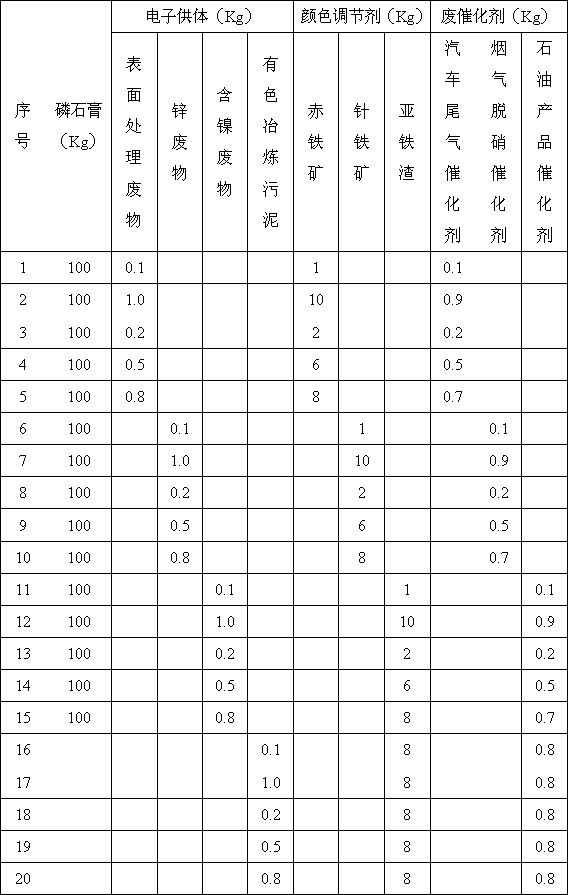

[0027] (1) Add electron donor (0.1-1.0% of gypsum mass), color regulator (1-10% of gypsum mass), spent catalyst (0.1-0.9% of The total number is about 107), and after being stirred and aged for 30 days, it is dried in a rotary dryer at 300°C to obtain a dry material.

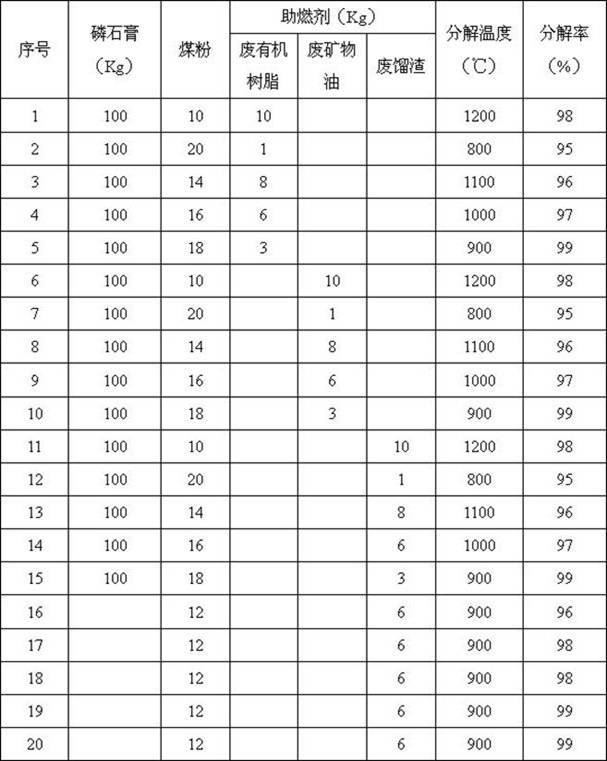

[0028] (2) Add the dry material to the cyclone preheater equipped with the fluidized decomposition furnace, and put coal powder (10-20% of the mass of gypsum) and combustion aid (1-10% of the mass of gypsum) into the fluidized furnace, and dry the material in the Fully decompose in a boiling decomposition furnace at 800-1200°C to obtain sulfur oxide gas and colored calcium oxide.

[0029] The following table is 20 embodiments numbered 1-20.

[0030]

[0031]

[0032] From Example 1-Example 20, it can be concluded that the decomposition rate of phosphogypsum is greater than or equal to 95%. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com