Method for one-step controllable preparation of porous nitrogen-doped carbon material

A nitrogen-doped carbon material technology is applied in the field of one-step preparation of porous nitrogen-doped carbon materials, which can solve the problems of complex synthesis procedures, cumbersome steps, and unenvironmentally friendly processes, and achieves wide raw material sources, large product yield, and good repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of porous nitrogen-doped carbon material, its preparation method comprises the steps:

[0032] 1) Weigh 1g of glucose and 1g of urea respectively, place them in a small beaker, and keep them warm at 90°C for 30 minutes to slowly melt the mixed solids to form a jelly;

[0033] 2) Continue to heat up the obtained jelly to 120°C, and magnetically stir for about 2 hours to form a transparent and clear brown colloidal solution;

[0034] 3) The obtained colloidal solution was placed in a microwave oven and microwaved at a power of 900W for 5 minutes to form a black fluffy foamy solid, which was ground to obtain a yellow-brown solid;

[0035] 4) The obtained yellow-brown solid was pretreated at 350° C. for 4 hours under a nitrogen atmosphere, then heated to 900° C. for 10 hours, and cooled to room temperature to obtain a porous nitrogen-doped carbon material.

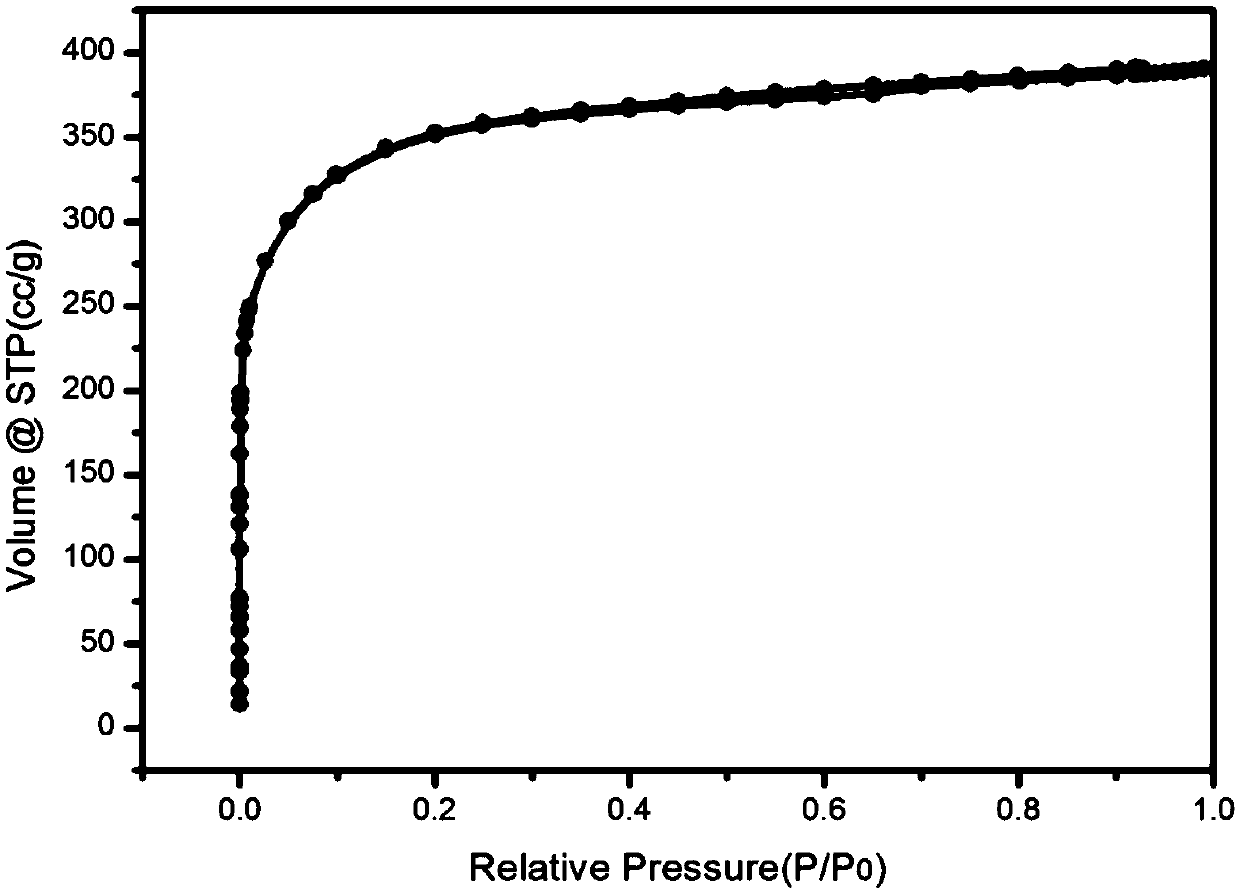

[0036] figure 1 For the nitrogen adsorption / desorption curve of the product obtained in the present inventio...

Embodiment 2

[0038] A kind of porous nitrogen-doped carbon material, its preparation method comprises the steps:

[0039] 1) Weigh 1g of glucose and 2g of urea respectively, place them in a small beaker, and keep them warm at 100°C for 30 minutes to slowly melt the mixed solids and form a jelly;

[0040] 2) Continue to heat up the obtained jelly to 120°C, and magnetically stir for about 2 hours to form a transparent and clear brown colloidal solution;

[0041] 3) The obtained colloidal solution was placed in a microwave oven and microwaved at a power of 900W for 5 minutes to form a black fluffy foamy solid, which was ground to obtain a yellow-brown solid;

[0042] 4) The obtained yellow-brown solid was pretreated at 350° C. for 4 hours under a nitrogen atmosphere, then heated to 700° C. for 10 hours, and cooled to room temperature to obtain a porous nitrogen-doped carbon material.

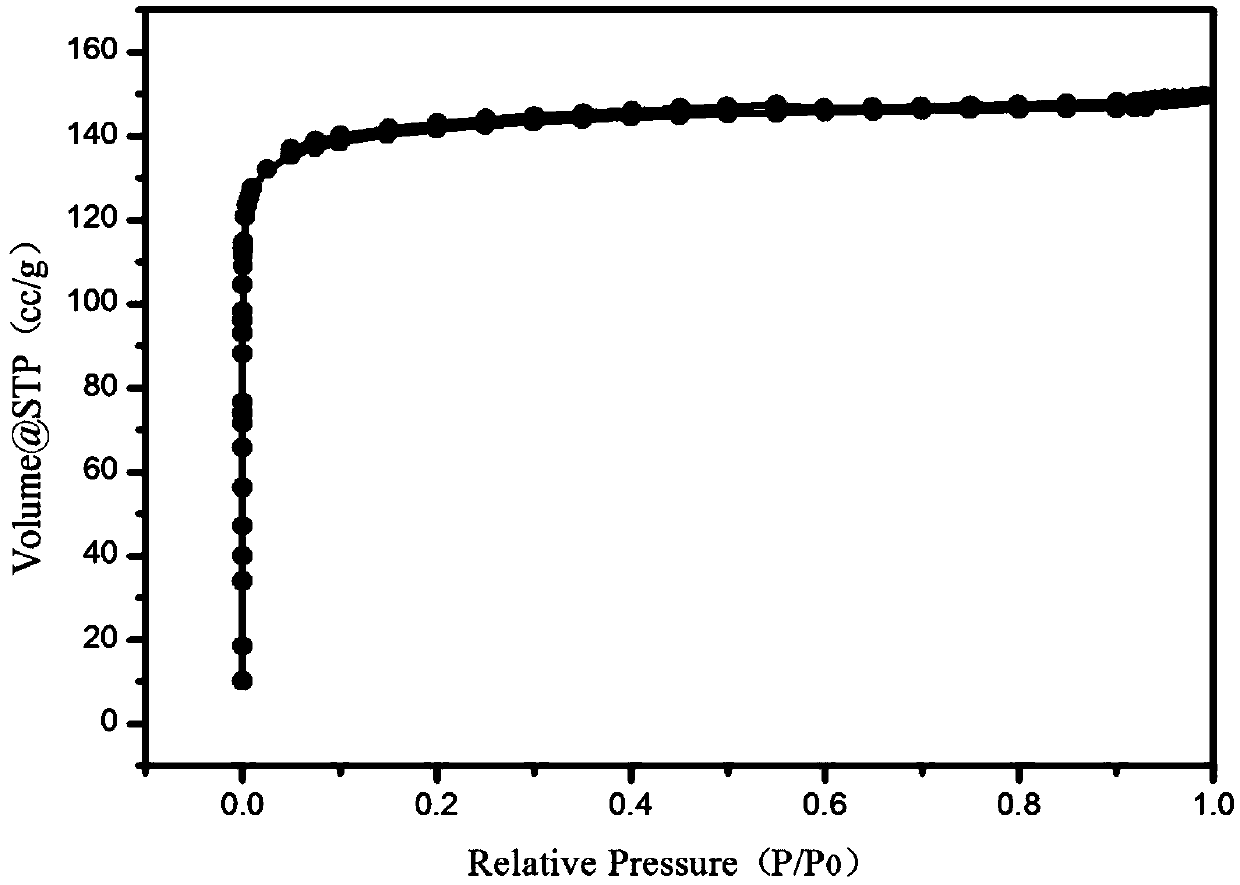

[0043] figure 2 It is the nitrogen adsorption / desorption curve of the product obtained in the present inv...

Embodiment 3

[0046] A kind of porous nitrogen-doped carbon material, its preparation method comprises the steps:

[0047] 1) Weigh 2g of sucrose and 1g of urea respectively, place them in a small beaker, and keep them warm at 90°C for 30 minutes to slowly melt the mixed solids to form a jelly;

[0048] 2) Continue to heat up the obtained jelly to 120°C, and magnetically stir for about 2 hours to form a transparent and clear brown colloidal solution;

[0049] 3) The obtained colloidal solution was placed in a microwave oven and microwaved at a power of 900W for 5 minutes to form a black fluffy foamy solid, which was ground to obtain a yellow-brown solid;

[0050]4) The obtained yellow-brown solid was pretreated at 350° C. for 4 hours under a nitrogen atmosphere, then heated to 800° C. for 10 hours, and cooled to room temperature to obtain a porous nitrogen-doped carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com