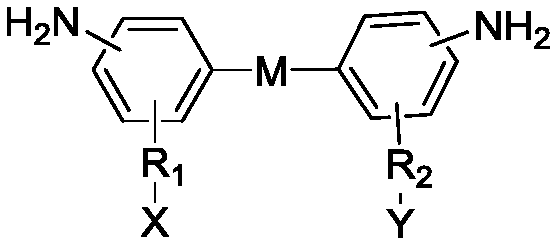

Liquid crystal aligning agent, liquid crystal alignment film and liquid crystal display element

A liquid crystal aligning agent and solvent technology, used in liquid crystal materials, optics, instruments, etc., can solve the problems of poor liquid crystal orientation, aggravated rubbing stripes, and narrow rubbing process window, and achieve uniform and stable liquid crystal orientation, excellent anti-rubbing performance, and increased The effect of anchoring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

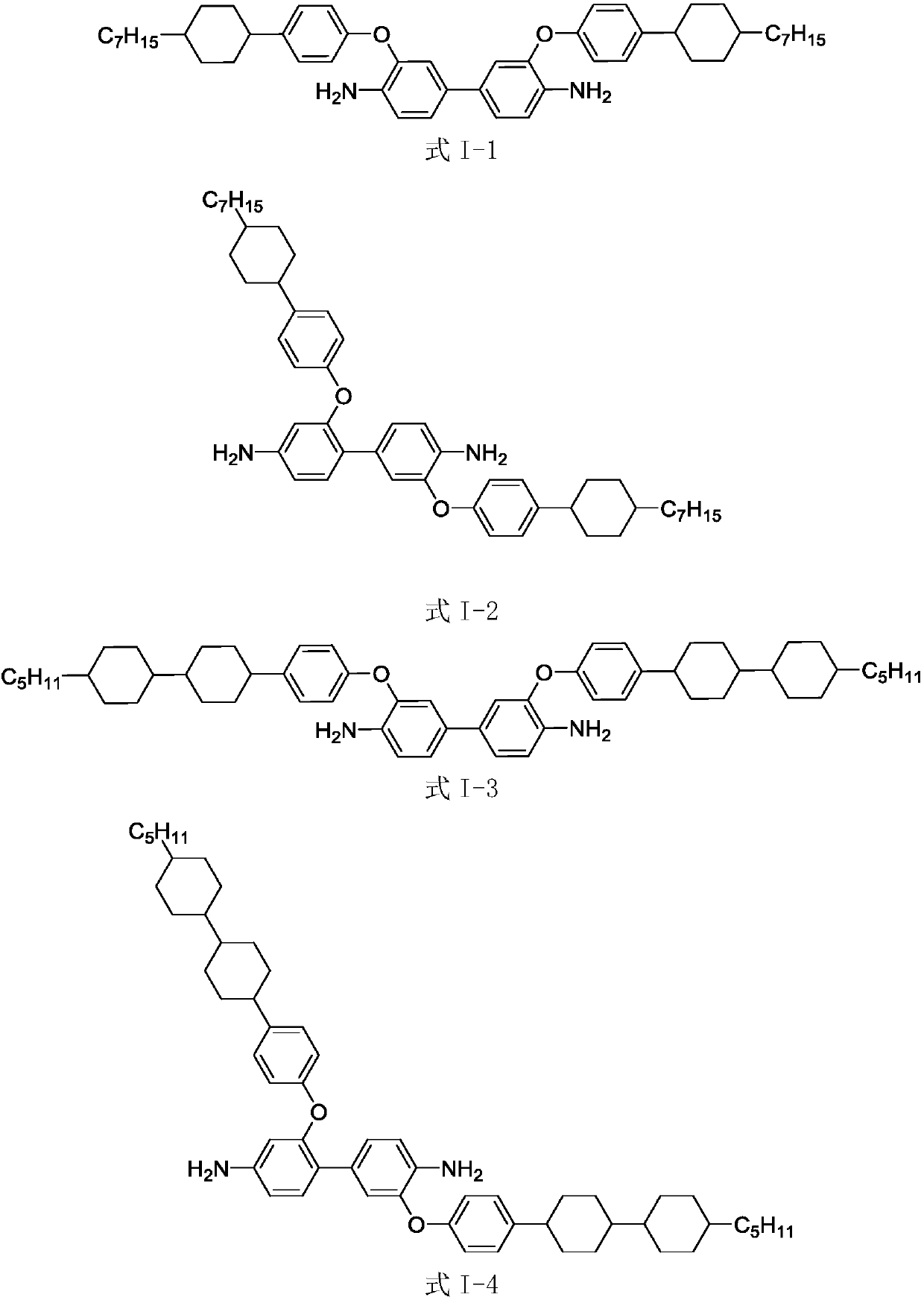

[0067] The compound represented by structural formula (I-1) can be synthesized according to the following synthetic route 1:

[0068]

[0069] Synthetic route 1

[0070] (1) Synthesis of compound b-1-1a

[0071] 3,3'-dichloro-4,4'-nitrobiphenyl (31.3g, 100 mmol), 4-(4-heptylcyclohexyl)phenol (54.88g, 200 mmol), potassium carbonate (30.40 g, 220 mmol) and 500 g DMF were stirred and heated to 120 ° C for 6 hours, then the temperature was lowered and the solution was filtered, the filtrate was added to 3 L of water, stirred for 0.5 h, filtered, and the obtained solid was added with 50 g of toluene and 150 g of DMF , stirred and heated to complete dissolution, cooled to crystallize, filtered and dried to obtain a solid (b-1-1a), measured by HPLC-MS [M+1] = 789.25.

[0072] (2) Synthesis of compound b-1-1

[0073] The obtained compound b-1-1a (39.47g, 50 mmol), 5% palladium carbon (2.61g, 70% water, 30% solid content) and 400gDMF were put into a 1L autoclave, and the autoclav...

Synthetic example 2

[0079] The compound represented by structural formula (I-7) can be synthesized according to the following synthetic route 2:

[0080]

[0081] Synthetic route 2

[0082] (1) Synthesis of compound b-1-7a

[0083] Drop into p-2-chloro-4-fluoronitrobenzene (17.50 g, 100 mmol), 3-chloro-4-nitrophenol (18.16 g, 105 mmol), potassium carbonate ( 27.64g, 200 mmol) 500g of toluene, stirred and heated to reflux for 6 hours, then cooled to filter the solution, and the filtrate was de-dried, added 300g of toluene to the obtained solid, stirred to raise the temperature to 50°C, cooled to room temperature, and acidified with hydrochloric acid to pH=1 Filtrate, add 150 g of toluene to the obtained solid, stir to heat up to complete dissolution, cool down to crystallize, filter, and dry to obtain a solid (b-1-7a), measured by HPLC-MS [M+1]=328.87.

[0084] (2) Synthesis of compound (b-1-7b)

[0085] Drop b-1-7a (16.40g, 50 mmoles), 4-(4-heptylcyclohexyl) phenol (30.18g, 110 mmoles), potas...

Synthetic example 8-10

[0090] The compounds represented by the structural formulas (I-8) to (I-10) can be etherified with the corresponding parent compounds according to the synthesis route 2 and b-1-7a to obtain the corresponding nitro compounds, and then carry out nitro compounds through catalytic hydrogenation The reduction obtains corresponding diamino compound, and the compound high-resolution mass spectrometry data field elemental analysis results represented by structural formula (I-8) to (I-10) are shown in the following table:

[0091] The mass spectrometry elemental analysis data of each compound of table 2 synthesis example 8-10

[0092]

[0093] (2) Synthesis example of polymer A

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com