Preparation method and application of carbon-based supercapacitor electrode material

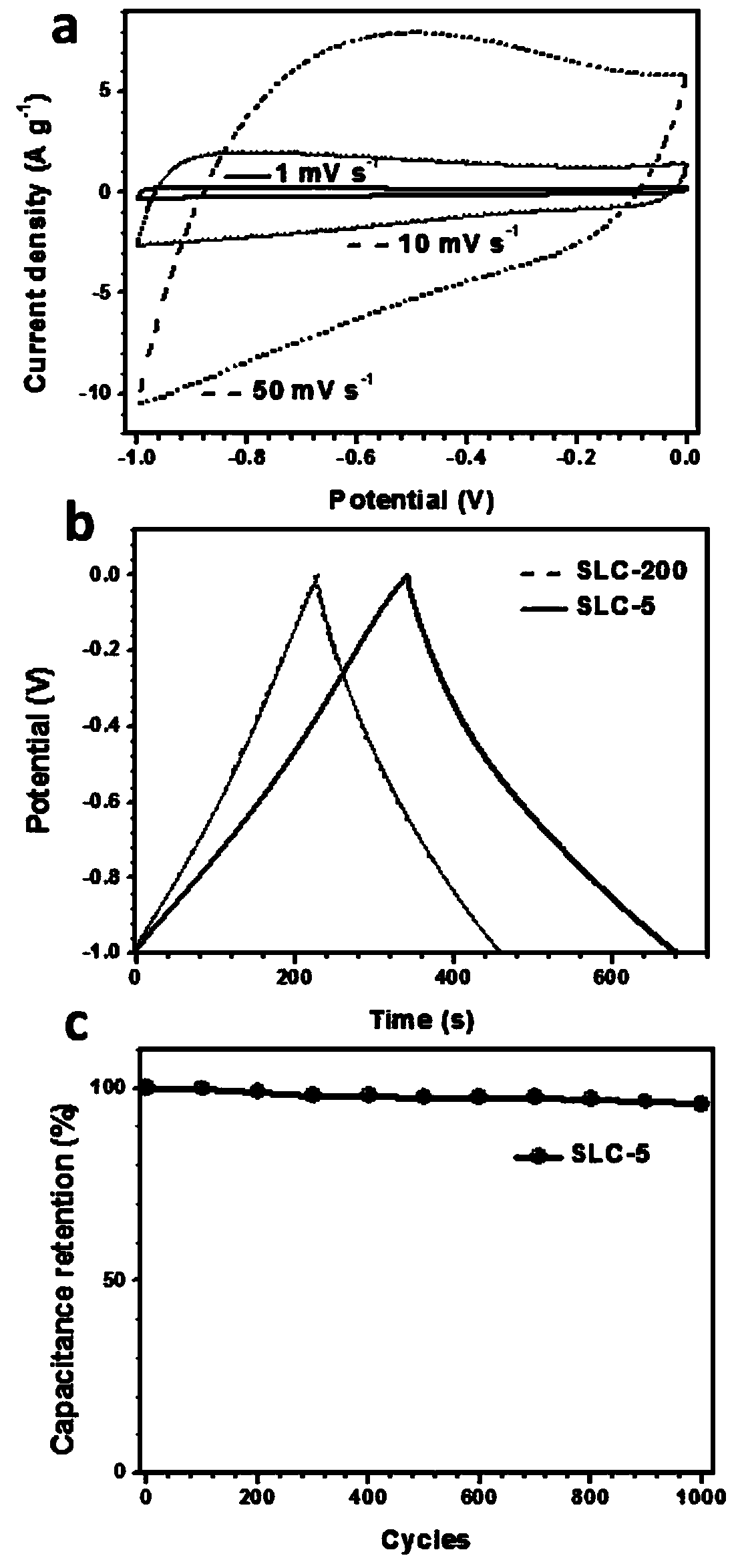

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of unfavorable capacitor application, limited electrolyte diffusion, complex processing technology, etc., and achieves low cost and low price. , the effect of high energy storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

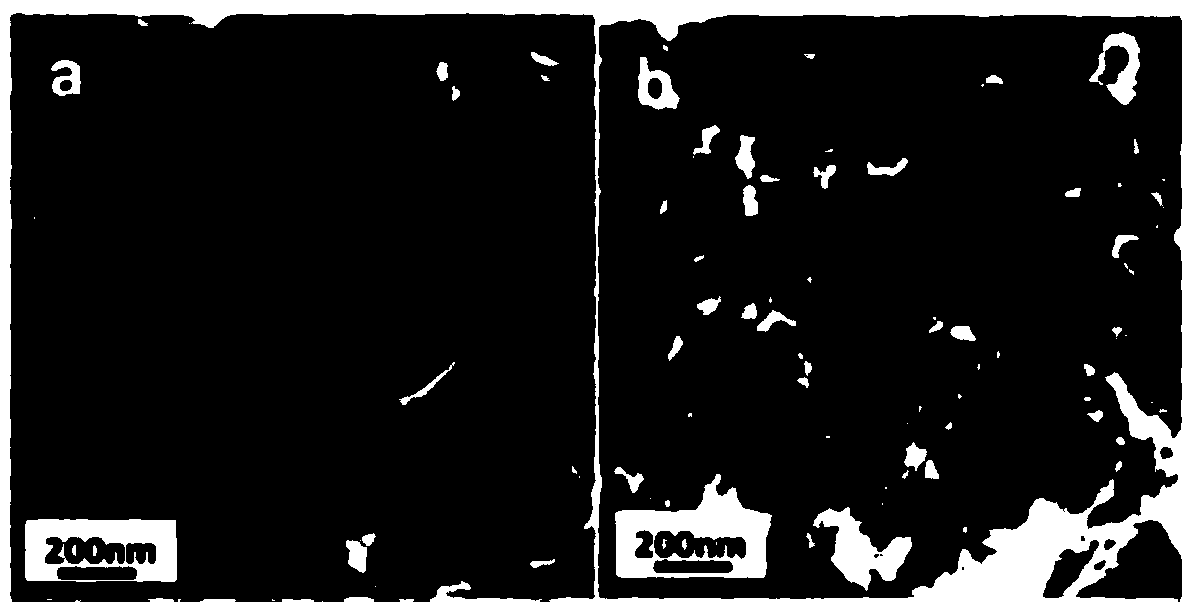

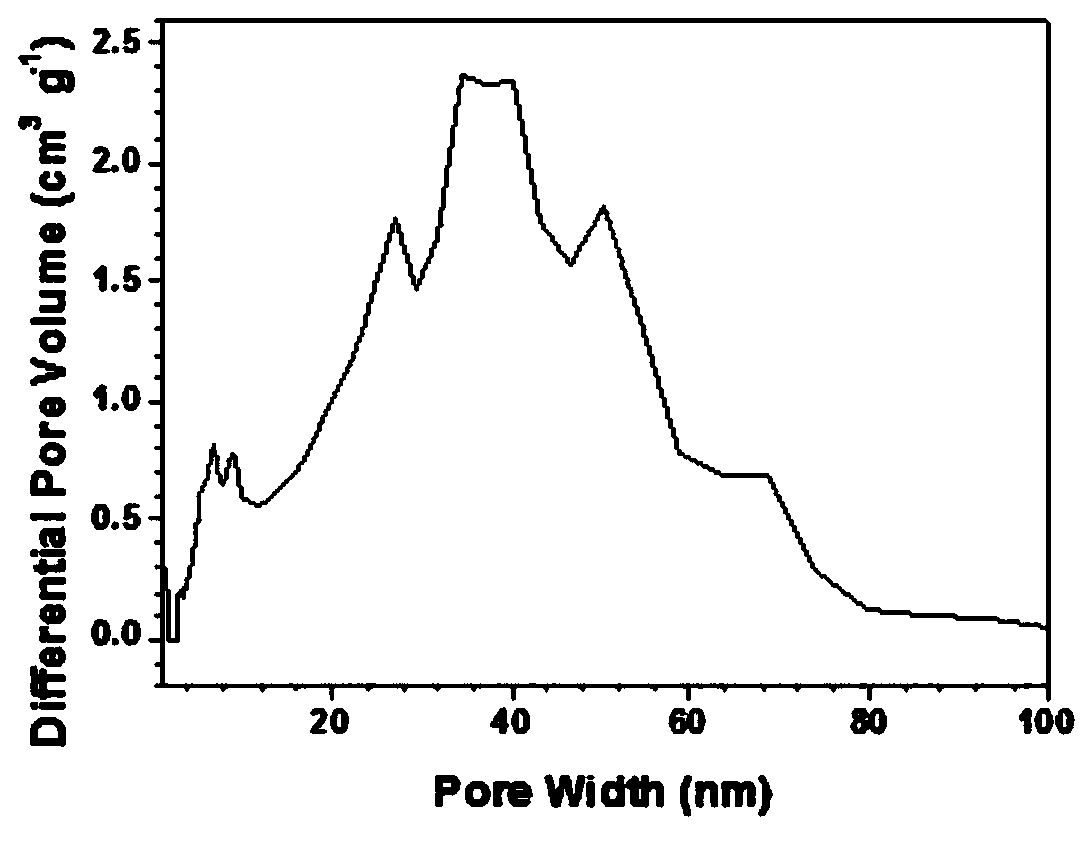

[0031] 0.237g lignin, 0.237g polyethylene oxide-polypropylene oxide-polyoxyethylene trialkylene oxide block copolymer and 0.118g silica nanospheres (5nm) were mixed and placed in 1.78g THF solution, stirred at room temperature for 1 h. The mixed solution was placed in a mold to volatilize and remove THF. After the solvent was completely removed to obtain a thin film of the mixture, the thin film of the mixture was heated in a high-temperature furnace at 800° C. for 1 h in nitrogen. After cooling, take it out and put it in 1mol L -1 In sodium hydroxide solvent, react at 80°C for 4h to remove silicon dioxide.

Embodiment 2

[0033] 6g of lignin, 1g of polyethylene oxide-polypropylene oxide-polyethylene oxide trialkylene oxide block copolymer and 1g of silica nanorods (200nm) were mixed in 2g of tetrahydrofuran solution, Stir at room temperature for 12 h, place the mixed solution in a mold to volatilize THF to remove THF, and obtain a thin film of the mixture after the solvent is completely removed, and heat the thin film of the mixture in a high-temperature furnace at 1000° C. for 8 h in argon. After cooling, take it out and put it in 5mol L -1 In sodium hydroxide solvent, react at 100°C for 12 hours to etch and remove silicon dioxide.

Embodiment 3

[0035] 1g of cellulose, 1g of polyethylene oxide-polypropylene oxide-polyoxyethylene trioxyalkylene block copolymer and 3g of silica nanospheres (100nm) were mixed in 5g of tetrahydrofuran solution, Stir at room temperature for 6h. After the solvent was completely removed to obtain a mixture film, the mixture film was placed in a high-temperature furnace at 850° C. and heated in argon for 5 h. After cooling, take it out and place it in 3mol L -1 In sodium hydroxide solvent, react at 90°C for 8 hours to etch and remove silicon dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com