Magnesium ion battery negative electrode material prepared by manganese acetate tetrahydrate glycerol solvent method

A manganese acetate negative electrode, magnesium ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of small specific capacity, limited magnesium deposition-dissolution efficiency, short circuit of positive and negative electrodes, etc., and achieve charge-discharge cycle performance. Excellent, good research and development prospects, good effect of electrochemical reaction reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

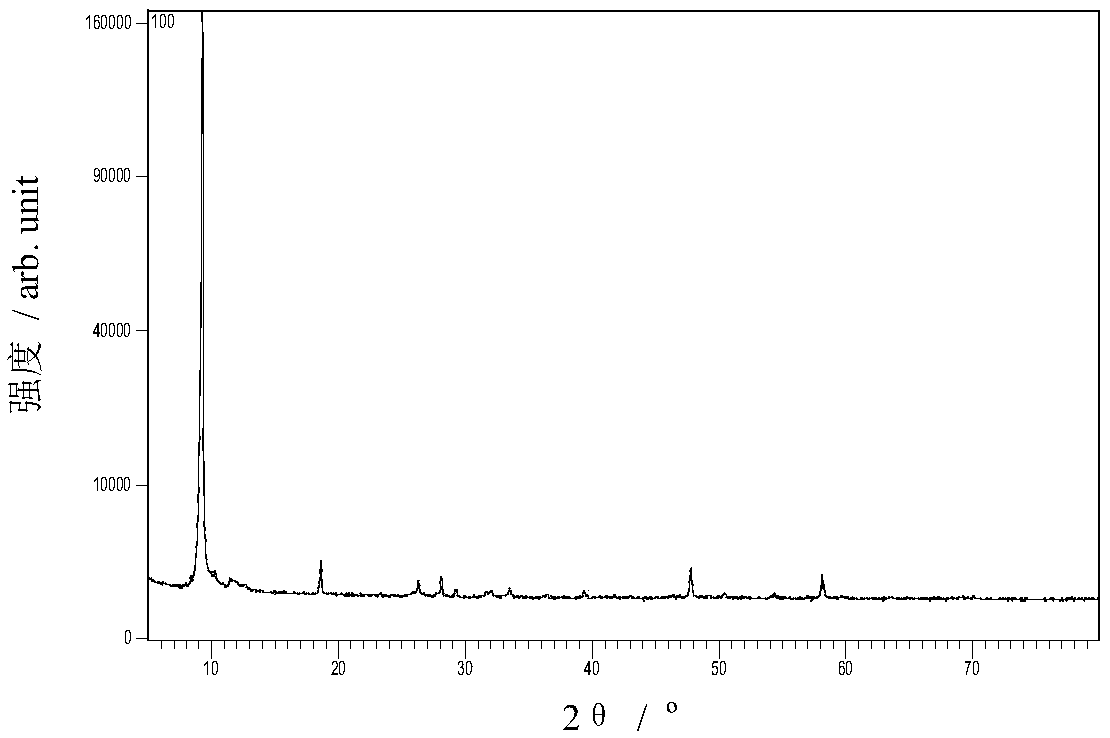

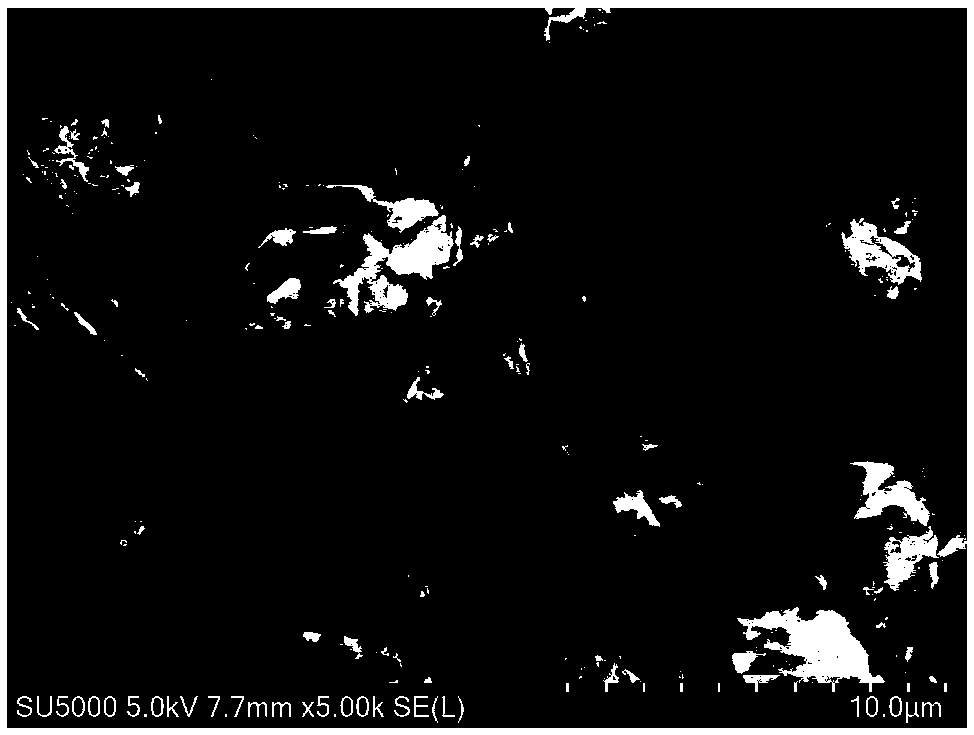

[0014] (1) Disperse 12.25 g of commercially available analytically pure manganese acetate tetrahydrate in 100 mL of glycerol, stir, heat to 120 ° C, keep warm and stir for 4 hours, then transfer the beaker to an oven that has been heated to 50 ° C in advance to keep warm and static After the powder product is completely settled at the bottom of the beaker, carefully pour out the upper layer of glycerin while it is hot, repeatedly wash the residual glycerin with absolute ethanol, and dry it in an oven at 60°C for 10 hours to obtain anhydrous manganese acetate. The XRD spectrum and the SEM photo of anhydrous manganese acetate are shown in figure 1 , figure 2 , the results show that anhydrous manganese acetate is a layered structure.

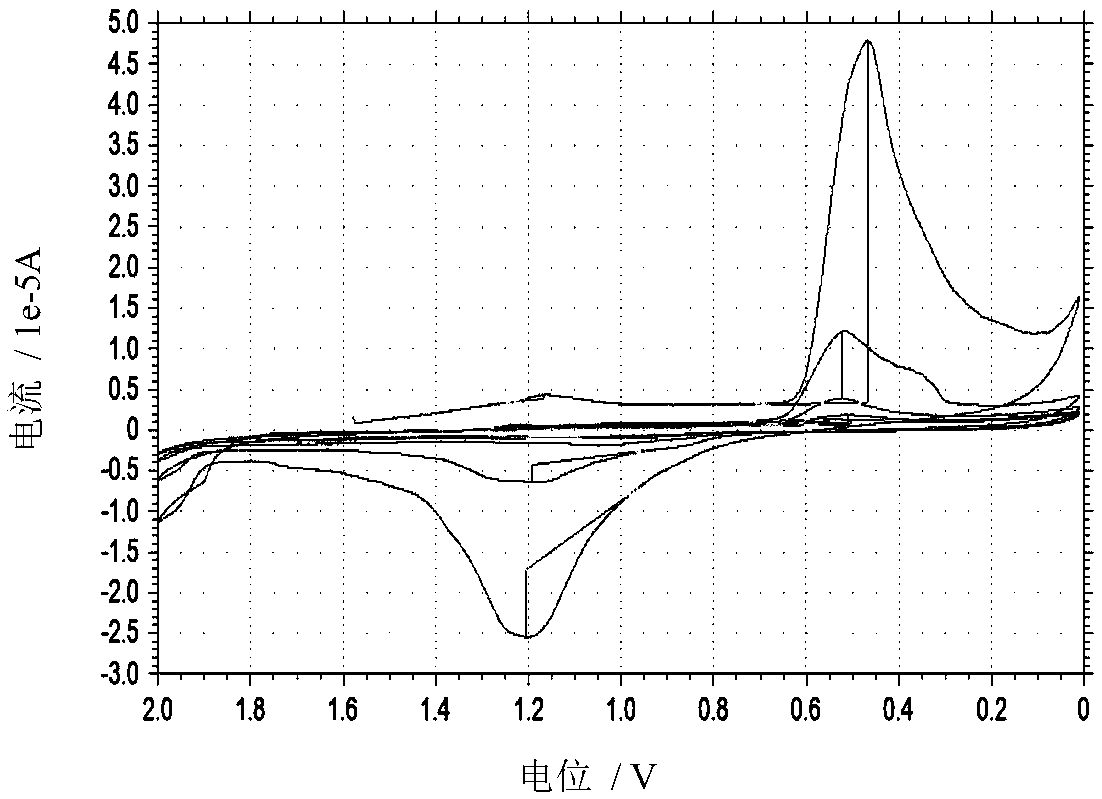

[0015] (2) Fully grind and mix the anhydrous manganese acetate prepared in step (1), acetylene black, and polyvinylidene fluoride (PVDF) binder in an agate mortar in a mass ratio of 7:2:1, and add dropwise to mix Analytical pure N-methylpyrrolid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com