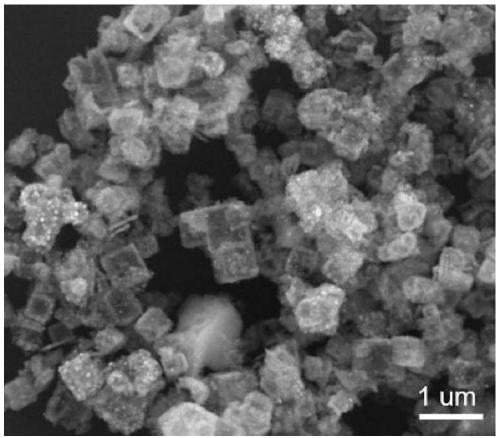

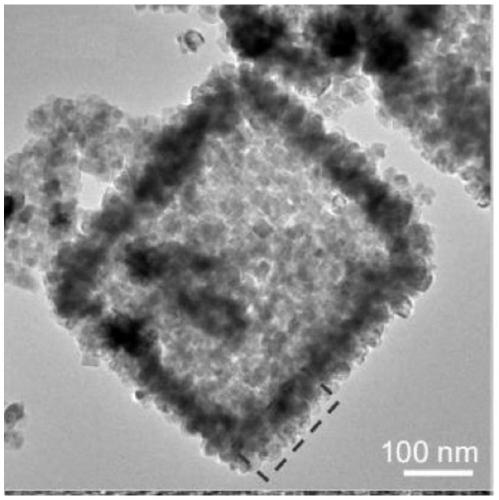

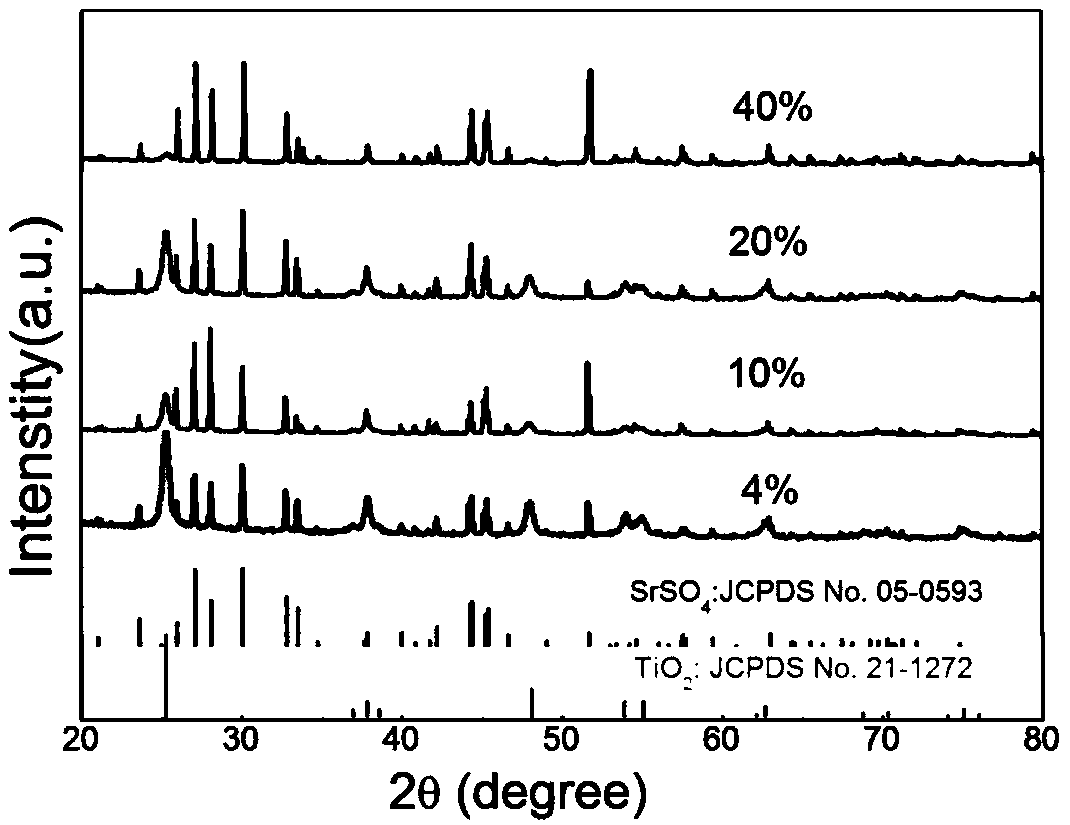

Porous thin-wall titanium dioxide/strontium sulfate heterojunction hollow nanocube and preparation method thereof

A technology of titanium dioxide and hollow nanometers, which is applied in the field of porous thin-walled titanium dioxide/strontium sulfate heterojunction hollow nanocubes and its preparation, and can solve problems such as low carrier transport rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation method of porous thin-walled titania / strontium sulfate heterojunction hollow nanocube is carried out according to the following steps:

[0045] a Preparation of cubic strontium titanate: mix strontium carbonate and titanium dioxide in a molar ratio of 1:1, add water with a mass ratio of 20% to mixture 2, and then add a sufficient amount of alkaline substance to keep it at In an alkaline reaction environment, the alkaline substance is a mixture of potassium hydroxide and sodium hydroxide at a mass ratio of 1:0.5; then react at a temperature of 160°C for 36 hours, then cool and wash away Alkaline substances until the pH is neutral, and finally dried to obtain cubic strontium titanate;

[0046] b Heating reaction: add 2.0 mol / L sulfuric acid and the cubic strontium titanate prepared in step b into a sealed tank at a mass ratio of 30 to 80:1, and react in a temperature environment of 250° C. for 8 hours;

[0047] c washing and drying: take out the rea...

Embodiment 2

[0049] A kind of preparation method of porous thin-walled titania / strontium sulfate heterojunction hollow nanocube is carried out according to the following steps:

[0050] a Preparation of cubic strontium titanate: mix strontium carbonate and titanium dioxide in a molar ratio of 1:1, and then add a sufficient amount of alkaline substance to keep it in an alkaline reaction environment. The alkaline substance is hydrogen Potassium oxide and sodium hydroxide are mixed in a mass ratio of 1:1.7; then reacted in a temperature environment of 250°C for 12 hours, then cooled and washed away alkaline substances until the pH is neutral, and finally dried to obtain cubic titanium strontium acid;

[0051] b Heating reaction: add 0.8 mol / L sulfuric acid and the cubic strontium titanate prepared in step b into a sealed tank at a mass ratio of 30 to 80:1, and react in a temperature environment of 160°C for 36 hours;

[0052] c washing and drying: take out the reaction product of step b and ...

Embodiment 3

[0054] A kind of preparation method of porous thin-walled titania / strontium sulfate heterojunction hollow nanocube is carried out according to the following steps:

[0055] a Preparation of cubic strontium titanate: mix strontium carbonate and titanium dioxide in a molar ratio of 1:1, add water with a mass ratio of 10% to mixture 2, and then add a sufficient amount of alkaline substance to keep it at In an alkaline reaction environment, the alkaline substance is a mixture of potassium hydroxide and sodium hydroxide in a mass ratio of 1:0.72; then react in a temperature environment of 200°C for 24 hours, then cool and wash away Alkaline substances until the pH is neutral, and finally dried to obtain cubic strontium titanate;

[0056] b Heating reaction: add 1.2mol / L sulfuric acid and the cubic strontium titanate prepared in step b into a sealed tank at a mass ratio of 30 to 80:1, and react in a temperature environment of 200°C for 24 hours;

[0057] c Washing and drying: Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com