Recovery system and recovery method for dimethylacetamide in ultra-filtration membrane production wastewater

A technology for the production of dimethylacetamide and waste water, which is applied in the separation/purification of carboxylic acid amide, sustainable manufacturing/processing, chemical industry, etc. It can solve the problems of high energy consumption, steam consumption, complicated process, etc., and achieve equipment investment Less, improve economic efficiency, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

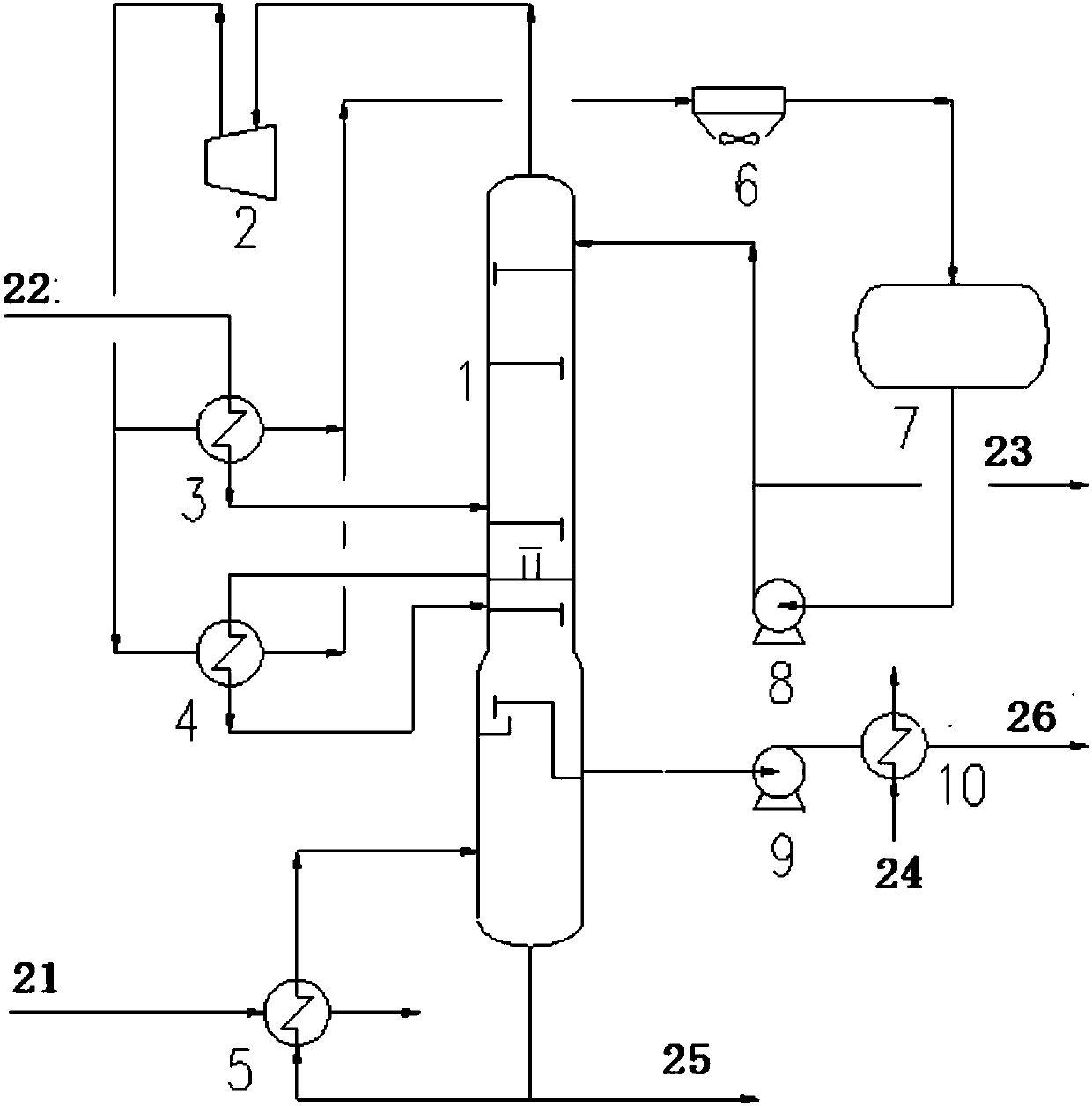

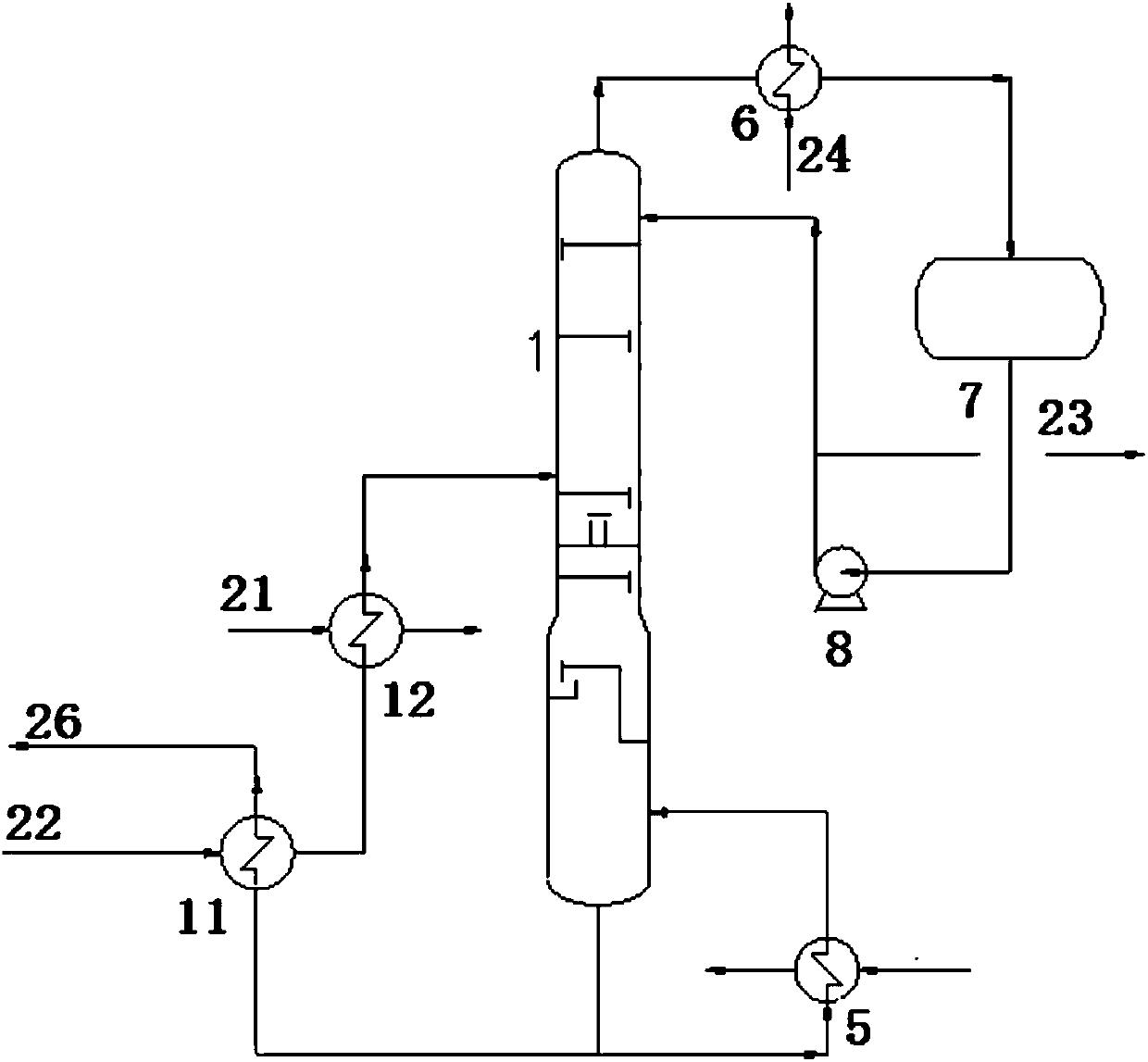

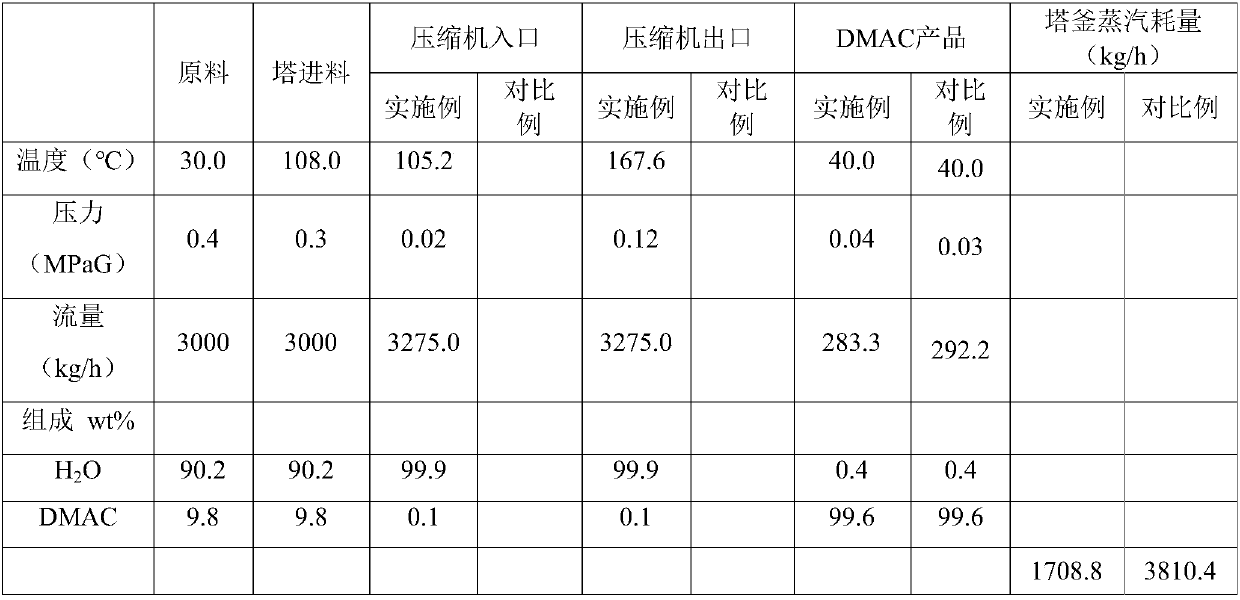

[0056] like figure 1 Shown is a recovery system for dimethylacetamide in ultrafiltration membrane production wastewater.

[0057] The system includes: refining tower 1, steam compressor 2, feed preheater 3, intermediate reboiler 4, tower kettle reboiler 5, refining tower condenser 6, reflux tank 7, reflux pump 8, product Discharge pump 9 and product cooler 10;

[0058] Refining tower 1 top is provided with water vapor compressor 2; Described refining tower condenser 6 is an air cooler; The dimethylacetamide product extraction line is arranged on the refining tower side line;

[0059] The wastewater feed line is connected to the feed preheater 3 and then connected to the middle of the refining tower; the refining tower 1 is provided with an intermediate reboiler 4 and a tower kettle reboiler 5; the outlet pipeline at the top of the refining tower 1 is connected to the steam compressor 2, and the water vapor The outlet pipeline of the compressor 2 is divided into two paths, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com