Clean production process of high-viscosity sodium alginate

A technology of sodium alginate and production process, which is applied in the field of clean production process of high-viscosity sodium alginate, can solve the problems of inability to meet the requirements of low-calcium products, high pseudoplastic viscosity, and rapid viscosity decrease, and saves reaction time, Guaranteed high viscosity and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

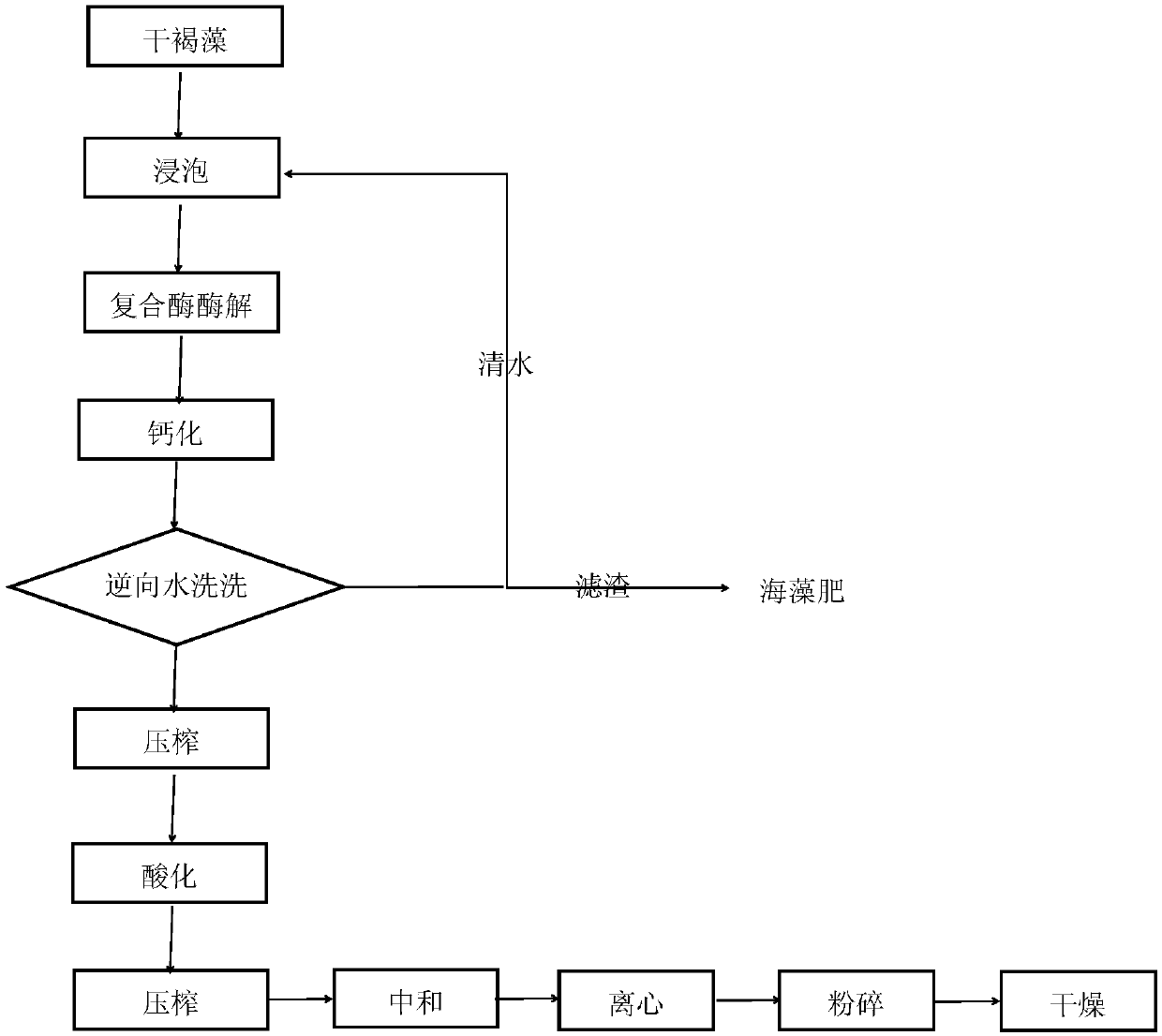

Image

Examples

Embodiment 1

[0033] (1) Dried brown algae soaking: put the brown algae into the enzymatic hydrolysis tank to fully rehydrate, the amount of water added is about 8 times, and the rehydration time: 6h;

[0034] (2) Composite enzyme enzymatic hydrolysis: adjust the temperature of the enzymolysis tank to 40°C, the pH is 4.5, add the compound enzyme (protease: cellulase: pectinase = 1:1:1.2), the addition amount is dry brown algae weight 1 %, enzymatic hydrolysis reaction for 3 hours, the purpose is to completely decompose the protein, pectin, cellulose, etc. in brown algae;

[0035] (3) Calcification: add calcium chloride to the enzymolysis tank until the concentration of calcium chloride is 5%, so that the alginate radicals therein are fully calcified and converted into fibrous calcium alginate;

[0036] (4) Reverse water washing: the calcium alginate fiber is transported to a high position with a conveyor belt, and a water jet is connected to the high position to perform reverse washing on t...

Embodiment 2

[0044] (1) Dried brown algae soaking: put the brown algae into the enzymatic hydrolysis tank to fully rehydrate, the amount of water added is about 9 times, and the rehydration time: 7h;

[0045] (2) Compound enzyme enzymolysis: adjust the temperature of the enzymolysis tank to 45°C, pH 5.0, add compound enzyme (protease: cellulase: pectinase = 1:1:1.3), the amount added is the weight of dry brown algae 2 %, enzymatic hydrolysis reaction for 4 hours, the purpose is to completely decompose the protein, pectin, cellulose, etc. in brown algae;

[0046] (3) Calcification: add calcium chloride to the enzymolysis tank until the concentration of calcium chloride is 5%, so that the alginate radicals therein are fully calcified and converted into fibrous calcium alginate;

[0047] (4) Reverse water washing: the calcium alginate fiber is transported to a high position with a conveyor belt, and a water jet is connected to the high position to perform reverse washing on the algae fiber. ...

Embodiment 3

[0055] (1) Dried brown algae soaking: put the brown algae into the enzymatic hydrolysis tank to fully rehydrate, the amount of water added is about 10 times, and the rehydration time: 8h;

[0056] (2) Compound enzyme enzymolysis: adjust the temperature of the enzymolysis tank to 55°C, pH 5.5, add compound enzyme (protease: cellulase: pectinase = 1:1:1.5), the amount added is dry brown algae weight 3 %, enzymatic hydrolysis reaction for 5 hours, the purpose is to completely decompose the protein, pectin, cellulose, etc. in brown algae;

[0057] (3) Calcification: add calcium chloride to the enzymolysis tank until the concentration of calcium chloride is 5%, so that the alginate radicals therein are fully calcified and converted into fibrous calcium alginate;

[0058] (4) Reverse water washing: the calcium alginate fiber is transported to a high position with a conveyor belt, and a water jet is connected to the high position to perform reverse washing on the algae fiber. Water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com