Flame-retardant paint for fabric and flame-retardant cloth applying flame-retardant paint

A technology for flame-retardant coatings and fabrics, which is applied in the field of flame-retardant fabrics and flame-retardant coatings for fabrics. Combustibility, widening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

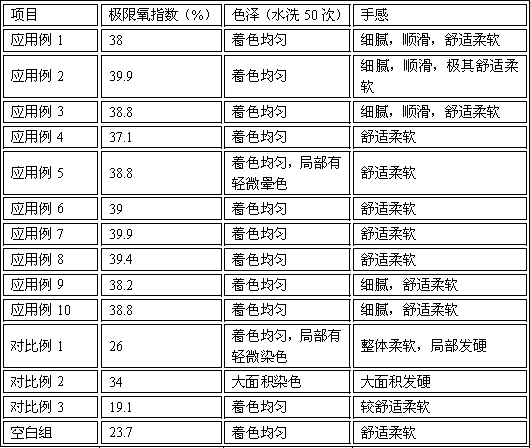

Examples

Embodiment 1

[0032] 60 g of silicone resin, 10 g of magnesium hydroxide with an average particle diameter of 5 μm, 10 g of hexamethylol melamine, 10 g of polyethylene glycol with an average molecular weight of 4000, and fatty alcohol polyoxygen with an addition number of ethylene oxide of 11 5g of vinyl ether was fully stirred and mixed to obtain the flame retardant coating of Example 1. Among them, the silicone resin is polymerized from polydimethylsiloxane and methyl hydrogen-containing silicone oil according to the silicon mass ratio of 3:1. The polymerization method and operation steps are conventional technical means for silicone resin polymerization. I won't repeat them here.

Embodiment 2

[0034] The difference between Example 2 and Example 1 is that the flame retardant coating in Example 2 is 50g of silicone resin, 8g of aluminum hydroxide with an average particle diameter of 10 μm, 12g of hexamethylolmelamine, and polyethylene with an average molecular weight of 4000. 16 g of diol and 4 g of fatty alcohol polyoxyethylene ether having an addition number of ethylene oxide of 16 were fully stirred and mixed. Among them, the silicone resin is polymerized from polydimethylsiloxane and methyl hydrogen-containing silicone oil according to the silicon mass ratio of 7:1.

Embodiment 3

[0036]The difference between Example 3 and Example 1 is that the flame-retardant coating in Example 3 is 40g of silicone resin, 6g of magnesium hydroxide with an average particle diameter of 1 μm, 8g of hexamethylolmelamine, and polyethylene oxide with an average molecular weight of 4000. 12 g of diol and 2 g of fatty alcohol polyoxyethylene ether having an addition number of ethylene oxide of 14 were fully stirred and mixed. Among them, the silicone resin is polymerized from polydimethylsiloxane and methyl hydrogen-containing silicone oil according to the silicon mass ratio of 5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com