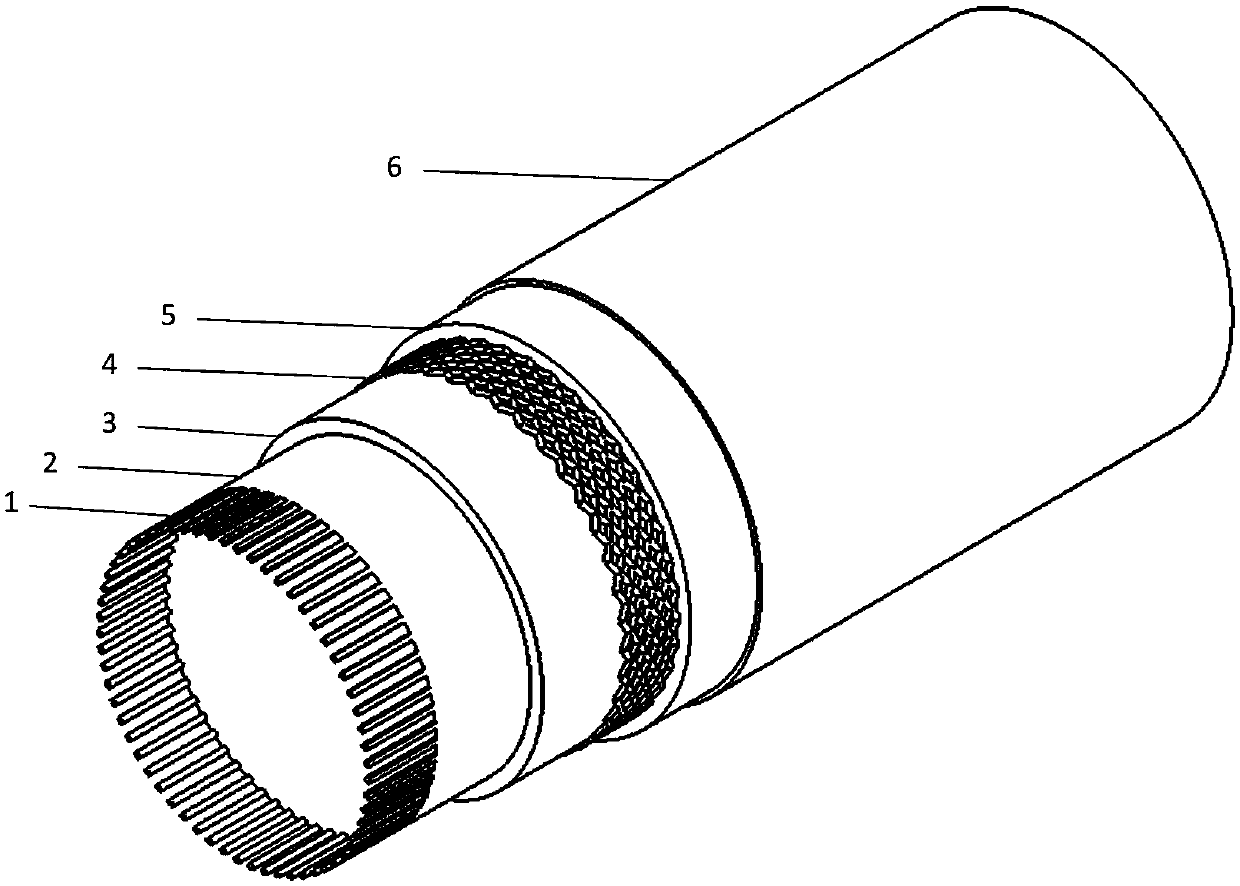

Fiber-reinforced compound hydrogel artificial blood vessel structure and molding method thereof

A technology of fiber-reinforced composite and artificial blood vessels, which is applied in the direction of human tubular structure devices, blood vessels, and pharmaceutical formulations. The effect of overall structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, the equipment composition includes the following contents: take a stainless steel optical shaft with a diameter of 5mm as the mandrel, and connect it to 42 stepper motors through a coupling, and the controller of the stepper motor is a single-chip microcomputer (the single-chip microcomputer model is 89C51 ), the single-chip microcomputer can control the rotation mode of the motor, which is divided into continuous operation and single-step operation, and can realize the conversion and speed regulation of the two. The axis is installed on the y-axis motion platform of the three-axis platform. Electrospinning and electrostatic direct writing nozzles are installed on the x-z motion platform of the three-axis motion platform. The nozzle is a 10ml medical disposable syringe. The material of the nozzle is 10% wt PCL (polycaprolactone dissolved in a solvent of dichloromethane: dimethylamide = 7:3), and the supply of the nozzle is provided by a micropump thr...

Embodiment 2

[0063] The equipment composition of this embodiment is the same as that of Embodiment 1.

[0064] A method for forming a fiber-reinforced composite hydrogel artificial blood vessel structure, the specific steps are as follows:

[0065] 1) Select a mandrel with a diameter of <6mm as the central axis of the artificial blood vessel, and use electrostatic direct writing technology to electrostatically write PCL fibers with a diameter of 30um on the mandrel. The fibers are arranged in parallel along the axis of the mandrel to form electrostatic direct writing fibers. Layer 1 1; adjust the relevant parameters of electrostatic direct writing: the distance between the needle and the mandrel is 4mm, the feeding speed is 1ml / h, the moving speed of the nozzle along the mandrel is 35mm / s, and the voltage applied to the needle is 2.5kv; Directly write the fiber The length of a single fiber is 10mm, and the distance between each fiber is 15um;

[0066] 2) Utilize the electrospinning techno...

Embodiment 3

[0073] The equipment composition of this embodiment is the same as that of Embodiment 1.

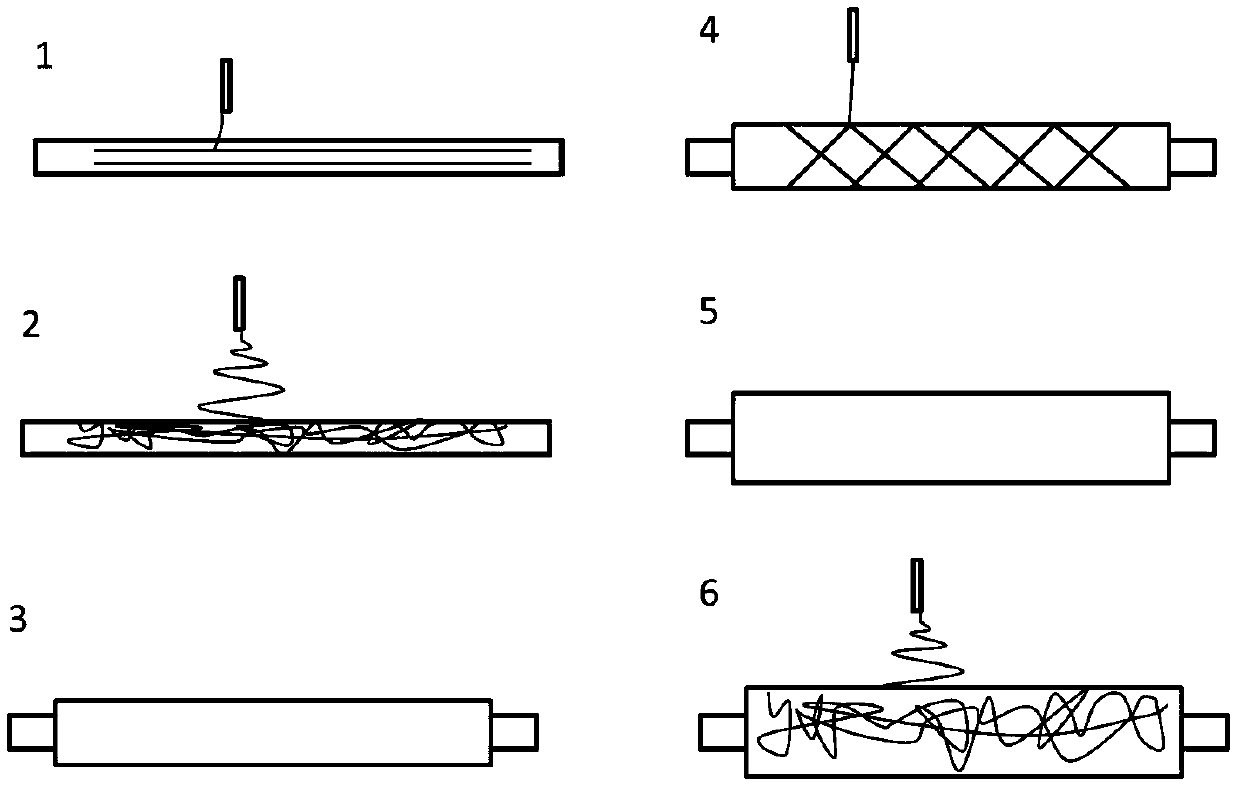

[0074] A method for forming a fiber-reinforced composite hydrogel artificial blood vessel structure, such as figure 2 As shown, the specific steps are as follows:

[0075] 1) Select a mandrel with a diameter of <6mm as the central axis of the artificial blood vessel, and use electrostatic direct writing technology to electrostatically write PCL fibers with a diameter of 50um on the mandrel. The fibers are arranged in parallel along the axis of the mandrel to form electrostatic direct writing fibers. Layer 1 1; adjust the relevant parameters of electrostatic direct writing: the distance between the needle and the mandrel is 7mm, the feeding speed is 2ml / h, the moving speed of the nozzle along the mandrel is 70mm / s, and the voltage applied to the needle is 4kv; The length of the root is 150mm, and the distance between each fiber is 100um;

[0076] 2) Utilize electrospinning technology, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com