Preparation method of nano-layered lithium nickel cobalt manganate

A nickel-cobalt lithium manganese oxide, nano-layered technology, applied in the field of lithium-ion battery cathode material preparation, to achieve the effects of short production cycle, good crystal form, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

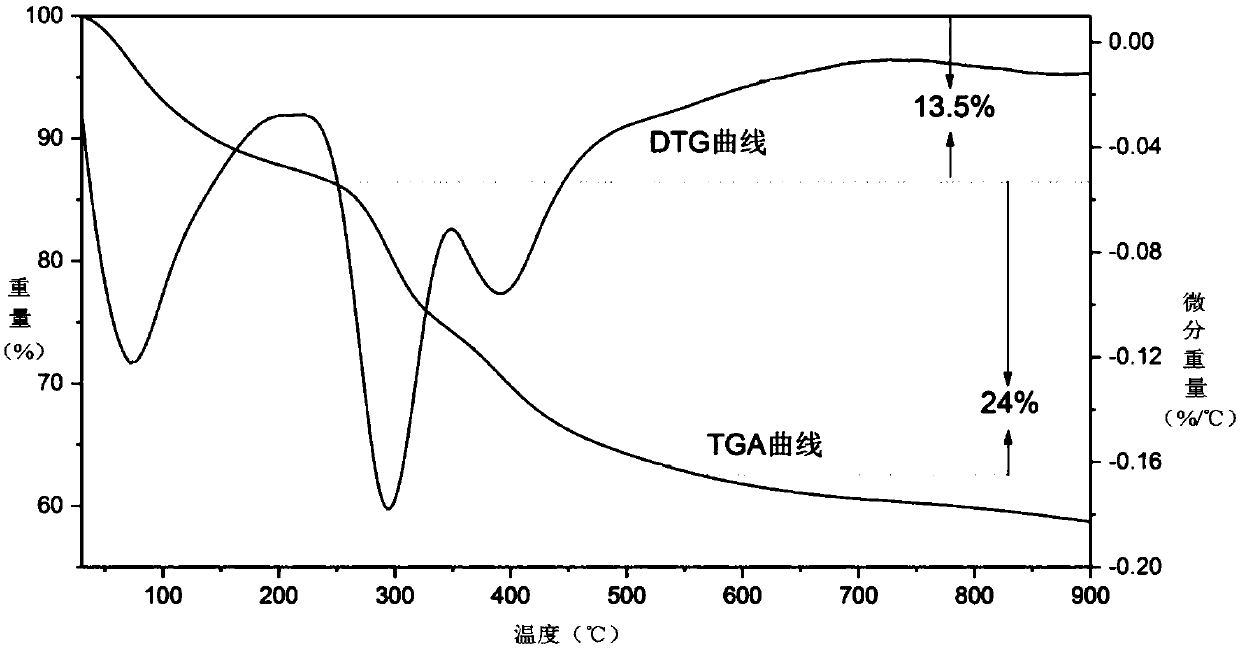

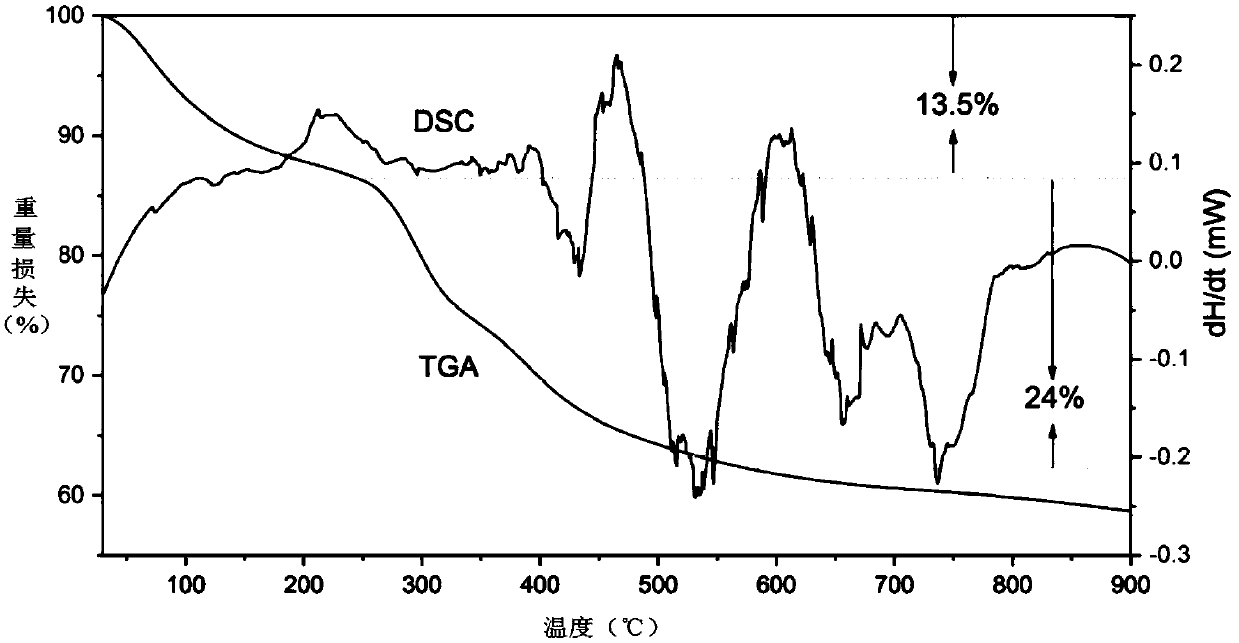

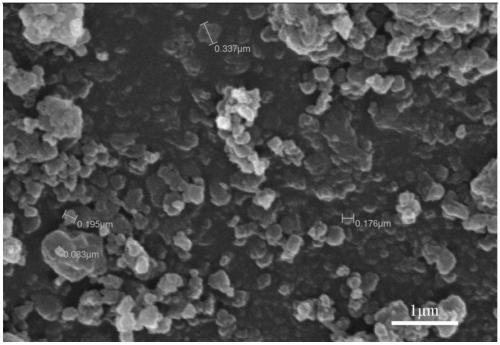

Image

Examples

Embodiment 1

[0041] A kind of nano-layered nickel-cobalt lithium manganese oxide (LiNi 0.5 co 0.2 mn 0.3 o 2 ) preparation method, comprising the following steps:

[0042] The first step is to prepare nanoscale Ni by low temperature co-precipitation method 0.5 co 0.2 mn 0.3 (OH) 2 Precursor, comprising the following preparation steps:

[0043] Take by weighing the nickel salt, cobalt salt, manganese salt that metal ion molar ratio is 5:3:2, and the antioxidant that takes by weighing 16g, it is dissolved in the distilled water (ice water) of 4L, is made into nickel, cobalt, manganese The total concentration of three metal ions is a mixed solution of 0.20mol / L; the solution is pumped into the supergravity reactor with a centrifugal pump, and the control switch for controlling the rotor of the supergravity reactor is opened, and the adjusting speed is 1200r / min, and the solution will Stay in the helical channel type rotating bed of the supergravity reactor and react under the effect o...

Embodiment 2

[0046] Embodiment 2 (comparative example 1)

[0047] With Example 1, the difference is that the reactor is a conventional common flask, carried out in a water bath of a magnetic stirrer, that is, the reaction is carried out under conventional gravity; The volumes of ammonia solution and sodium hydroxide solution added dropwise were 20 ml and 45 ml, respectively.

Embodiment 3

[0049] Same as Example 1, the difference is that the calcination temperature is 700°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com