Method for extracting elastin peptide

The technology of an elastin peptide and an extraction method, which is applied to the extraction field of elastin peptide, can solve the problems of complicated preparation process, low efficiency and high cost, and achieve the effects of high extraction efficiency, efficient utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

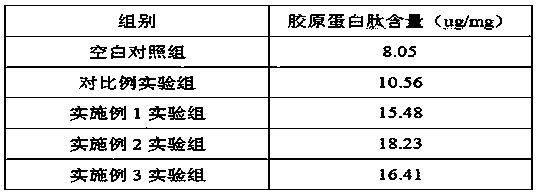

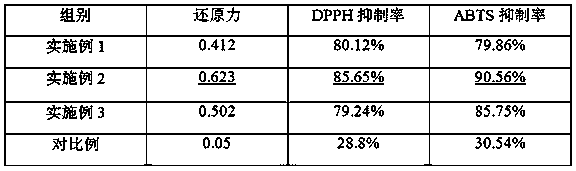

Examples

Embodiment 1

[0029] A method for extracting elastin peptides, comprising the following specific steps:

[0030] (1) Remove impurities such as fish meat from 500g fish cartilage, wash and mince, add 2 times the volume of 95% ethanol solution to soak for 6 hours, remove ethanol, repeat soaking with 95% ethanol solution once, remove ethanol, wash with distilled water twice ;

[0031] (2) Add 250mL of Tris-HCl buffer solution with pH 9.0 to every 100g of washed fish cartilage, then ultrasonic frequency 60KHz, power 150W, ultrasonic treatment time 30min;

[0032] (3) Add 400mg of elastase to every 100g of ultrasonically treated cartilage solution, incubate in a constant temperature water bath at 30°C, and shake at 150r / min for 1h;

[0033] (4) Heat the water bath to 40°C, heat it for 10 minutes to inactivate the enzyme, filter the enzymolysis solution, discard the filter residue, and collect the filtrate;

[0034] (5) For the filtrate obtained in step (4), select an ultrafiltration membrane w...

Embodiment 2

[0039] A method for extracting elastin peptides, comprising the following specific steps:

[0040] (1) Remove impurities such as fish meat from 1000g fish cartilage, wash and mince, add 3 times the volume of 95% ethanol solution to soak for 6 hours, remove ethanol, repeat immersion once in 95% ethanol solution for fish cartilage, remove ethanol, and wash with distilled water 2 times;

[0041] (2) Add 300mL Tris-HCl buffer solution with pH 9.0 to every 100g of washed fish cartilage, then ultrasonic frequency 60KHz, power 150W, ultrasonic treatment time 30min;

[0042] (3) Add 500mg of elastase to every 100g of ultrasonically treated cartilage solution, incubate in a constant temperature water bath at 30°C, and shake at 150r / min for 1h;

[0043] (4) Heat the water bath to 40°C, heat it for 10 minutes to inactivate the enzyme, filter the enzymolysis solution, discard the filter residue, and collect the filtrate;

[0044] (5) For the filtrate obtained in step (4), select an ultr...

Embodiment 3

[0049] A method for extracting elastin peptides, comprising the following specific steps:

[0050] (1) Remove impurities such as fish meat from 600g fish cartilage, wash and mince, add 2.5 times the volume of 95% ethanol solution to soak for 6 hours, remove ethanol, repeat immersion once in 95% ethanol solution for fish cartilage, remove ethanol, and wash with distilled water 2 times;

[0051] (2) Add 280mL of Tris-HCl buffer solution with pH 9.0 to every 100g of washed fish cartilage, then ultrasonic frequency 60KHz, power 150W, ultrasonic treatment time 30min;

[0052] (3) Add 450mg of elastase to every 100g of ultrasonically treated cartilage solution, incubate in a constant temperature water bath at 30°C, and shake at 150r / min for 1h;

[0053] (4) Heat the water bath to 40°C, heat it for 10 minutes to inactivate the enzyme, filter the enzymolysis solution, discard the filter residue, and collect the filtrate;

[0054](5) For the filtrate obtained in step (4), select an u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com