Implant comprising a calcium salt-containing composite powder having microstructred particles

A technology for composite powders and implants, used in calcium/strontium/barium compounds, drug combinations, household appliances, etc., can solve the problems of component surface quality and surface finish, component density is not completely satisfactory, and achieve good handleability. high quality, high body compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

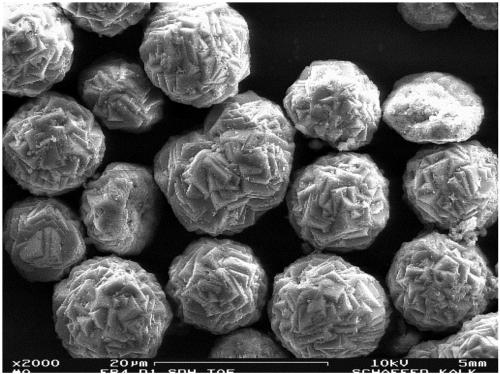

[0343] a CO 2 Gas mixture with 20% CO 2 and 80% N2 were introduced into 4 l of calcium bicarbonate suspension with a concentration of 75 g / l CaO at an initial temperature of 10°C. The gas flow rate is 300 l / h. The reaction mixture was stirred at 350 rpm and the heat of reaction was removed during the reaction. When the conductivity drops suddenly (the drop rate is greater than 0,5mS / cm / min and the drop value within 30 seconds is greater than 0,25mS / cm), refer to CaO (as a theoretical reference amount) to add 0.7% amino tri (methylene phosphine acid) was added to the suspension. When the reaction mixture is quantitatively carbonated into spherical calcium carbonate particles, the reaction to produce spherical calcium carbonate particles is complete. Wherein, the pH value of the reaction mixture at this moment is between 7 and 9. In the above case, the reaction was completed after approximately 2 hours and the pH of the reaction mixture was 7 at the end of the reaction.

...

example 2

[0346] 500ml of completely decalcified water is placed in a 1000ml beaker, while stirring, add 125g according to the spherical calcium carbonate particles of example 1 gained, and continue to stir the gained mixture for 5 minutes, slowly add 37.5g of 10% sodium metaphosphate ( NaPO 3 )n solution, and continued to stir the resulting mixture for 10 minutes, slowly added 75,0 g of 10% concentration of phosphoric acid, and continued to stir the resulting mixture for 20 hours. The precipitate was separated and dried overnight in a drying oven at a temperature of 130°C. The resulting spherical calcium carbonate particles likewise had an average particle diameter of 12 μm.

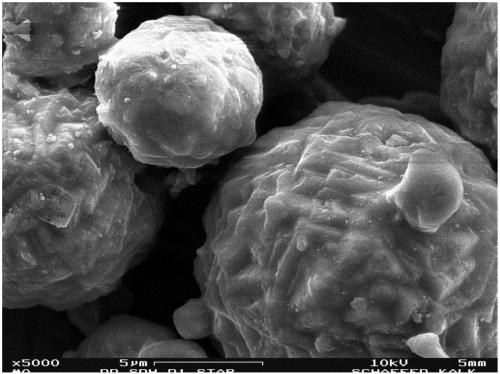

[0347] The REM image of spherical calcium carbonate particles as figure 2 shown. A thin layer of phosphate can be discerned on the surface of the spherical calcium carbonate particles.

example 3

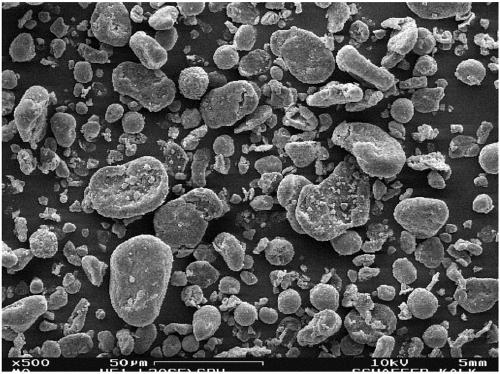

[0349] A composite powder of spherical calcium carbonate particles and a polylactide (PLLA) can be prepared using equipment NHS-1 by referring to the method described in JP 62083029A. The composite powder was cooled with cold water at 12°C. A polylactide particle 1 was used as a master batch and the calcium carbonate particle in Example 1 was used as a child particle (filler).

[0350] 39,5g of polylactide pellets with 26.3g of CaCO 3 The powders were mixed and filled at a rotational speed of 6400 U / min. The rotor speed of the device was set at 6400U / min (80m / s) and the added material was processed for 10 minutes. The NHS-1 grinding chamber reaches a maximum temperature of 35°C. A total of 7 runs were repeated with the same amount of material and machine settings. A total of 449 g of composite powder was obtained. The resulting composite powder was manually dry sieved through a 250um sieve. Sieve residue (size >250 μm) accounted for 0.4%.

[0351] The resulting composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com