Novel chelate fiber, preparation method thereof, and application of novel chelate fiber for detecting Pb(II) in preserved eggs

A chelating fiber, a new type of technology, applied in the field of chemistry, to achieve the effect of good selective adsorption, satisfactory accuracy and precision, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

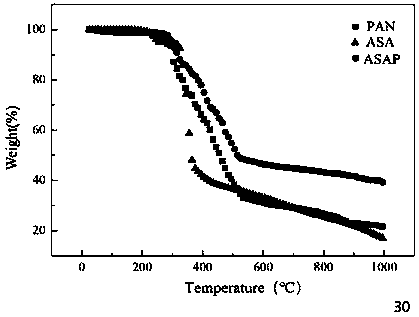

[0043] A kind of preparation method of novel chelating fiber, carries out following steps successively:

[0044] Accurately weigh 15 mg of polyacrylonitrile (PAN) fibers and soak them in 25 mL of deionized water for 12 hours to fully swell the fibers. Afterwards, the ligand o-aminophenolsulfonic acid (ASA) was added, the reaction molar ratio (PAN:ASA) was 1:4, deionized water was used as the solvent, and the mixture was stirred at a speed of 150rpm / min under nitrogen atmosphere for 1.5h, To exhaust the air, then rapidly heat up to 90°C, and stir at the same speed for 10h until the reaction ends. After the reaction stopped, the reaction fiber was washed with distilled water until it was colorless, and placed in a vacuum drying oven at 50° C. to dry to constant weight to obtain a new type of chelating fiber (ASAP).

[0045] After measuring the nitrogen content of the chelating fiber obtained by elemental analysis, by the following formula (1), (2) calculates the functional grou...

Embodiment 2

[0063] Change 90 DEG C of reaction temperature in embodiment 1 step (2) to 60 DEG C, 70 DEG C and 80 DEG C, other conditions are the same as embodiment 1, after measuring the content of N element in the chelating fiber with EA, calculate chelation by the above formula The conversion rate of the functional group of the fiber is obtained, and the influence of the reaction temperature on the conversion rate of the functional group of the chelated fiber is as follows: Figure 5 shown.

[0064] according to Figure 5 It can be seen that as the temperature of the system increases, the conversion rate of the functional group of the chelating fiber is constantly increasing. This is due to the fact that only a small amount of reactant -NH 2 It will diffuse into the interior of the PAN fiber, so the contact between the ligand and the matrix is less, and the reaction is not sufficient, which leads to a lower conversion rate of functional groups. When the temperature continues to ris...

Embodiment 3

[0066] Change the reaction molar ratio (parent matrix: ligand) 1:4 of step (2) in embodiment 1 to 1:2, 1:3 and 1:5, other conditions are identical with embodiment 1, obtain reaction molar ratio to chelate The influence of the functional group conversion rate of synthetic fibers such as Figure 6 shown.

[0067] according to Figure 6 It is known that when the reaction molar ratio is 4, the functional group conversion rate of ASAP is the highest, which may be due to the fact that when the reaction molar ratio is small, the -NH in the ligand 2 The concentration is small, and the contact area with the parent is small, resulting in an incomplete reaction. When the molar ratio of the reaction increases, it means that the dosage of the ligand increases, which makes -NH 2 As the concentration of β increases, the amount diffused into the interior of PAN fibers increases, and the contact between the matrix and the ligand increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com