Ceramic glaze and preparation method thereof

A ceramic glaze and mixing technology, applied in the glaze field, can solve the problems of glaze melting temperature and high temperature viscosity, poor grinding effect, incomplete grinding and other problems, so as to improve grinding effect, improve pulverization efficiency, improve The effect of glaze quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of ceramic glaze, each raw material is respectively 45% nepheline, 20% kaolin, 15% quartz, 8% modified flux, 7% zinc oxide powder and 5% cassiterite by weight percentage;

[0031] The modified flux is prepared as follows: first, the potassium feldspar is pulverized, ground and sieved and mixed evenly with boric acid, borax and quicklime powder, wherein the mesh number of the sieve is 200 mesh, and then Introduce it into a muffle furnace for gradient firing and pass in argon as a protective gas, and when the temperature is raised to 60 degrees, it is kept for 60 seconds, and when the temperature is raised to 100 degrees, it is kept for 45 seconds, and when the temperature is raised to 145 degrees, Hold for 30 seconds, and when the temperature rises to 450°C, hold for 15 seconds, and finally control the temperature at 850°C and keep it warm for 5 minutes, then cool and stand still to obtain a modified flux.

[0032] Wherein, each raw material in the modified flux i...

Embodiment 2

[0040] A kind of ceramic glaze, with embodiment 1.

[0041] The modified flux is prepared as follows: first, the potassium feldspar is pulverized, ground and sieved and mixed evenly with boric acid, borax and quicklime powder, wherein the mesh number of the sieve is 200 mesh, and then Introduce it into a muffle furnace for gradient firing and pass in argon as a protective gas, and when the temperature is raised to 60 degrees, it is kept for 60 seconds, and when the temperature is raised to 100 degrees, it is kept for 45 seconds, and when the temperature is raised to 145 degrees, Hold for 30 seconds, and when the temperature rises to 450°C, hold for 15 seconds, and finally control the temperature at 850°C and keep it warm for 5 minutes, then cool and stand still to obtain a modified flux.

[0042] Wherein, each raw material in the modified flux is respectively 40% boric acid, 20% borax, 20% potassium feldspar and 20% quicklime powder by weight percentage.

[0043] A method for...

Embodiment 3

[0045] A kind of ceramic glaze, with embodiment 1.

[0046] The modified flux is prepared as follows: Same as Example 1.

[0047] Wherein, each raw material in the modified flux is as follows by weight percentage: the same as in Example 1.

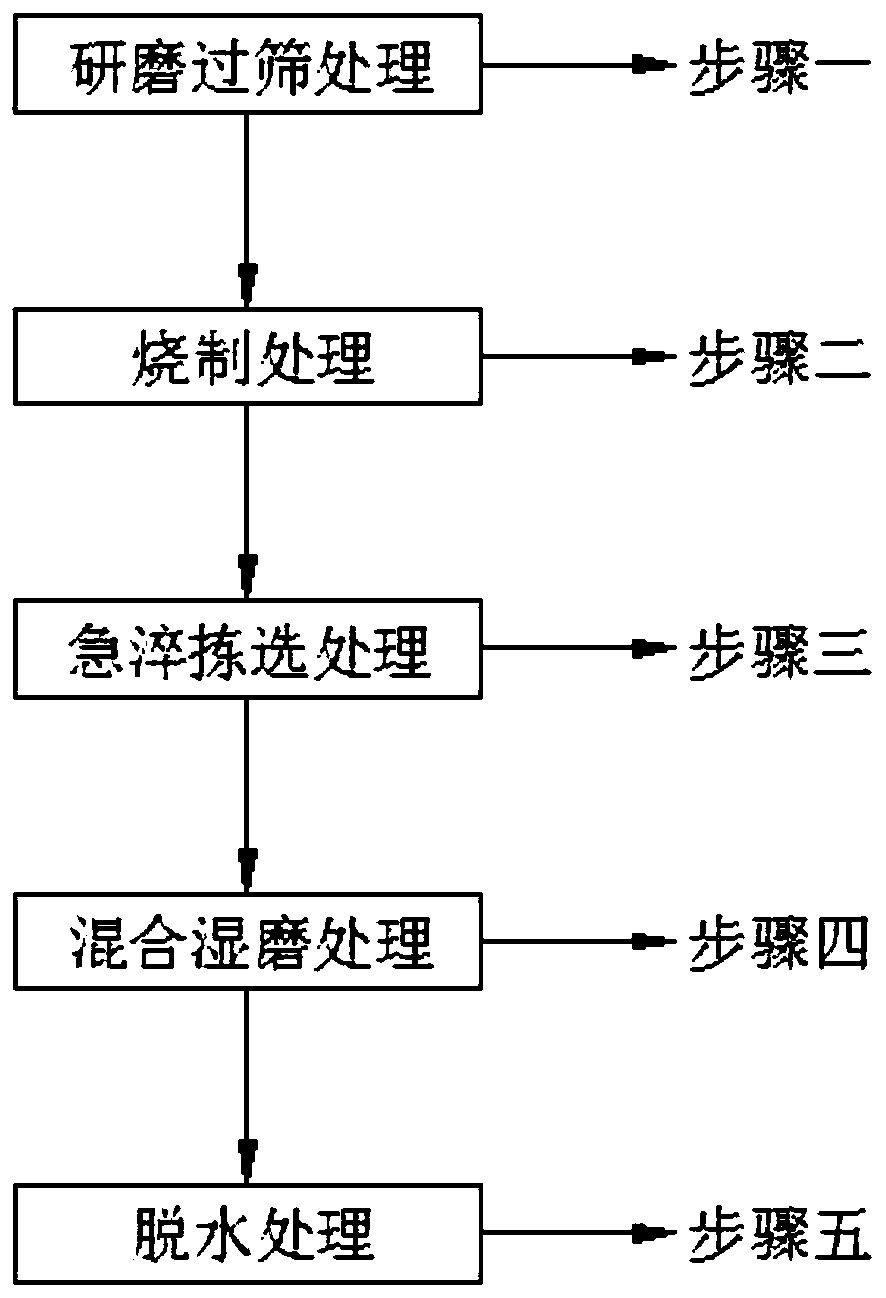

[0048] A preparation method for ceramic glaze, comprising the following steps:

[0049] 1) Grinding and sieving treatment: firstly import nepheline, quartz and cassiterite into a ball mill after weighing and ball milling for 60 minutes, export them, and sieve through a 40-mesh sieve to obtain a mixture A, And the ball milling medium in the ball mill is a ceramic ball, and the ball milling speed in the ball mill is controlled at 35% of the critical speed;

[0050] 2) Firing treatment: first mix the modified flux and zinc oxide powder with the mixture A evenly, then introduce it into the pool furnace for two firings and pass in argon as a protective gas, and the first firing The firing time is controlled at 3.5 hours, the firing temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com