Preparation method and application of potassium ion battery positive electrode material

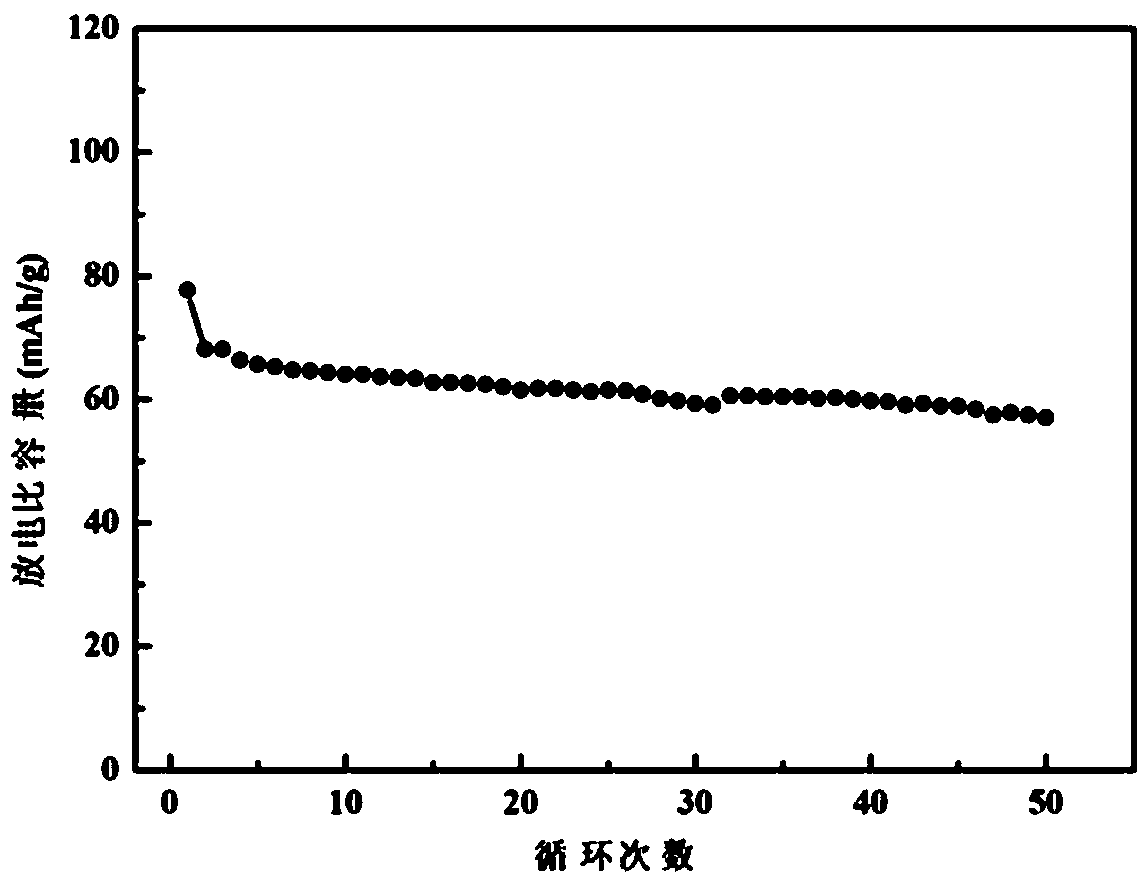

A battery cathode, potassium ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unstable cycle performance of potassium ion battery cathode materials, and achieve good cycle stability, good rate performance, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

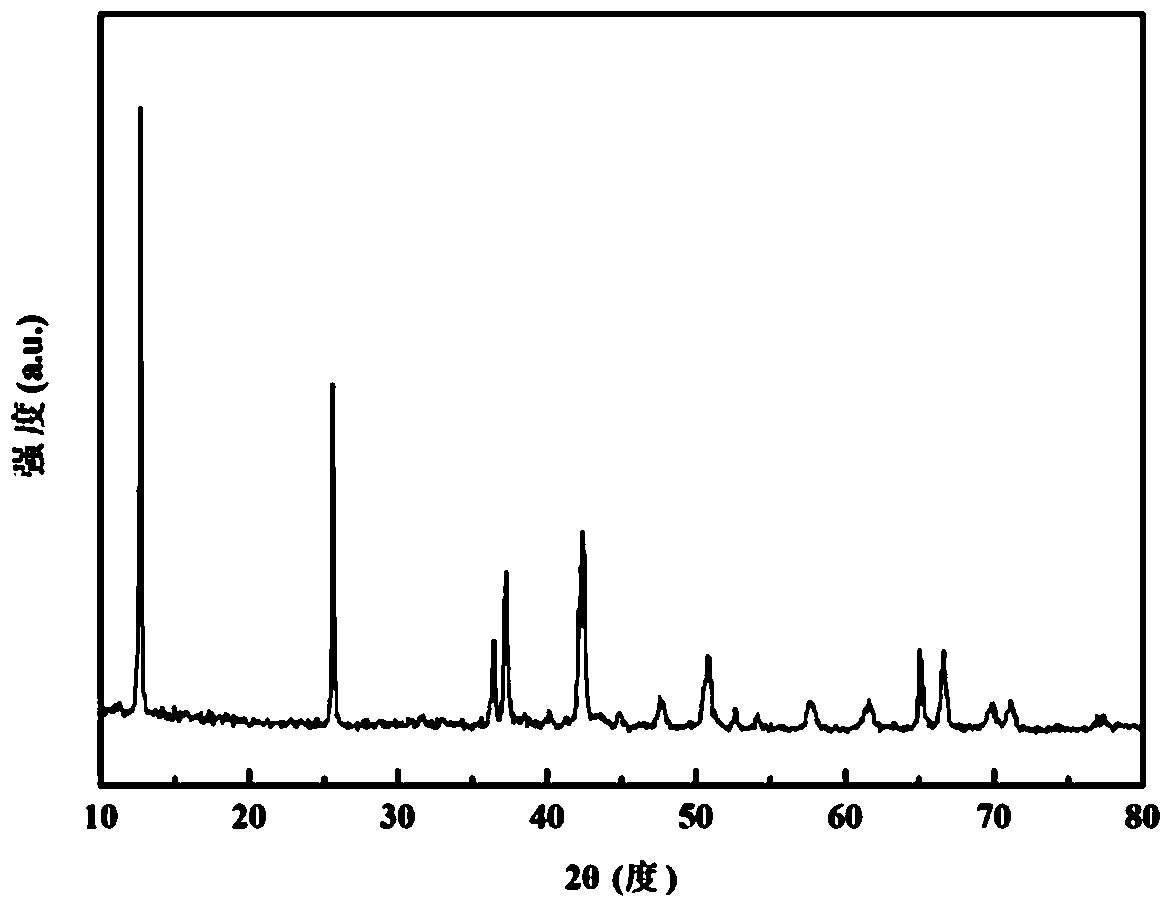

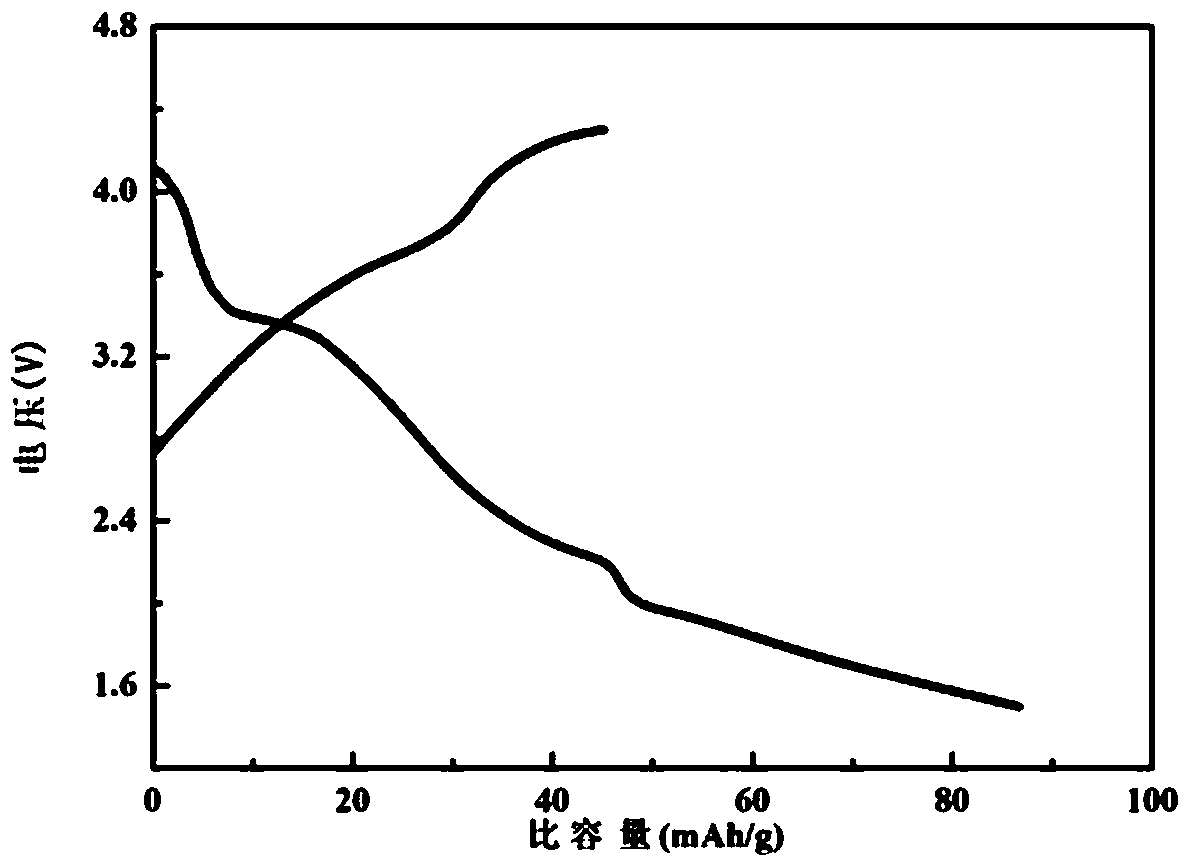

[0034] A kind of potassium ion battery K 0.5 Ni 0.15 co 0.15 mn 0.7 o 2 The preparation method of positive electrode material, preparation process is as follows:

[0035] (1) First, dissolve 3.7326g nickel acetate tetrahydrate in 15ml deionized water, dissolve 3.7362g cobalt acetate tetrahydrate in 15ml deionized water, dissolve 17.1563g manganese acetate tetrahydrate in 70ml deionized water, and then dissolve the three metal ions The salt solutions are mixed together and stirred evenly to obtain a mixed metal ion salt solution. At the same time, 12.607g of oxalic acid solid was dissolved in 100ml of deionized water to obtain an oxalic acid solution;

[0036](2) Put the beaker containing the oxalic acid solution obtained in step (1) into a water bath, and after the water temperature reaches 60°C, slowly drop the mixed metal ion salt solution obtained in step (1) into the oxalic acid solution, and control the stirring The speed is 400rmp, and after 5 hours of reaction, th...

Embodiment 2

[0041] A kind of potassium ion battery K 0.5 Ni 0.1 co 0.4 mn 0.5 o 2 The preparation method of positive electrode material, preparation process is as follows:

[0042] (1) First, dissolve 2.4884g nickel acetate tetrahydrate in 10ml deionized water, dissolve 9.9632g cobalt acetate tetrahydrate in 40ml deionized water, dissolve 12.2545g manganese acetate tetrahydrate in 50ml deionized water, and then dissolve the three metal ions The salt solutions are mixed together and stirred evenly to obtain a mixed metal ion salt solution. At the same time, 13.867g of oxalic acid solid was dissolved in 100ml of deionized water to obtain an oxalic acid solution;

[0043] (2) Put the beaker containing the oxalic acid solution obtained in step (1) into a water bath, and after the water temperature reaches 60°C, slowly drop the mixed metal ion salt solution obtained in step (1) into the oxalic acid solution, and control the stirring The speed is 400rmp, and after 5 hours of reaction, the...

Embodiment 3

[0050] A kind of potassium ion battery K 0.6 Ni 0.2 co 0.2 mn 0.6 o 2 The preparation method of positive electrode material, preparation process is as follows:

[0051] (1) First, dissolve 4.9768g nickel acetate tetrahydrate in 20ml deionized water, dissolve 4.9816g cobalt acetate tetrahydrate in 20ml deionized water, dissolve 14.7054g manganese acetate tetrahydrate in 60ml deionized water, and then dissolve the three metal ions The salt solutions are mixed together and stirred evenly to obtain a mixed metal ion salt solution. At the same time, 13.867g of oxalic acid solid was dissolved in 100ml of deionized water to obtain an oxalic acid solution;

[0052] (2) Put the beaker containing the oxalic acid solution obtained in step (1) into a water bath, and after the water temperature reaches 60°C, slowly drop the mixed metal ion salt solution obtained in step (1) into the oxalic acid solution, and control the stirring The speed is 450rmp, and after 6 hours of reaction, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com