High-capacity desulfurizing agent, and desulfurization system for circulating absorption, regeneration and utilization of desulfurizing agent

A technology of desulfurization system and desulfurization agent, which is applied in the direction of gas fuel, petroleum industry, and separation of dispersed particles, can solve the problems of difficult waste residue treatment, spontaneous combustion of desulfurization agent, and low desulfurization efficiency, so as to reduce operating costs and labor costs, reduce Power consumption of the pump and the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

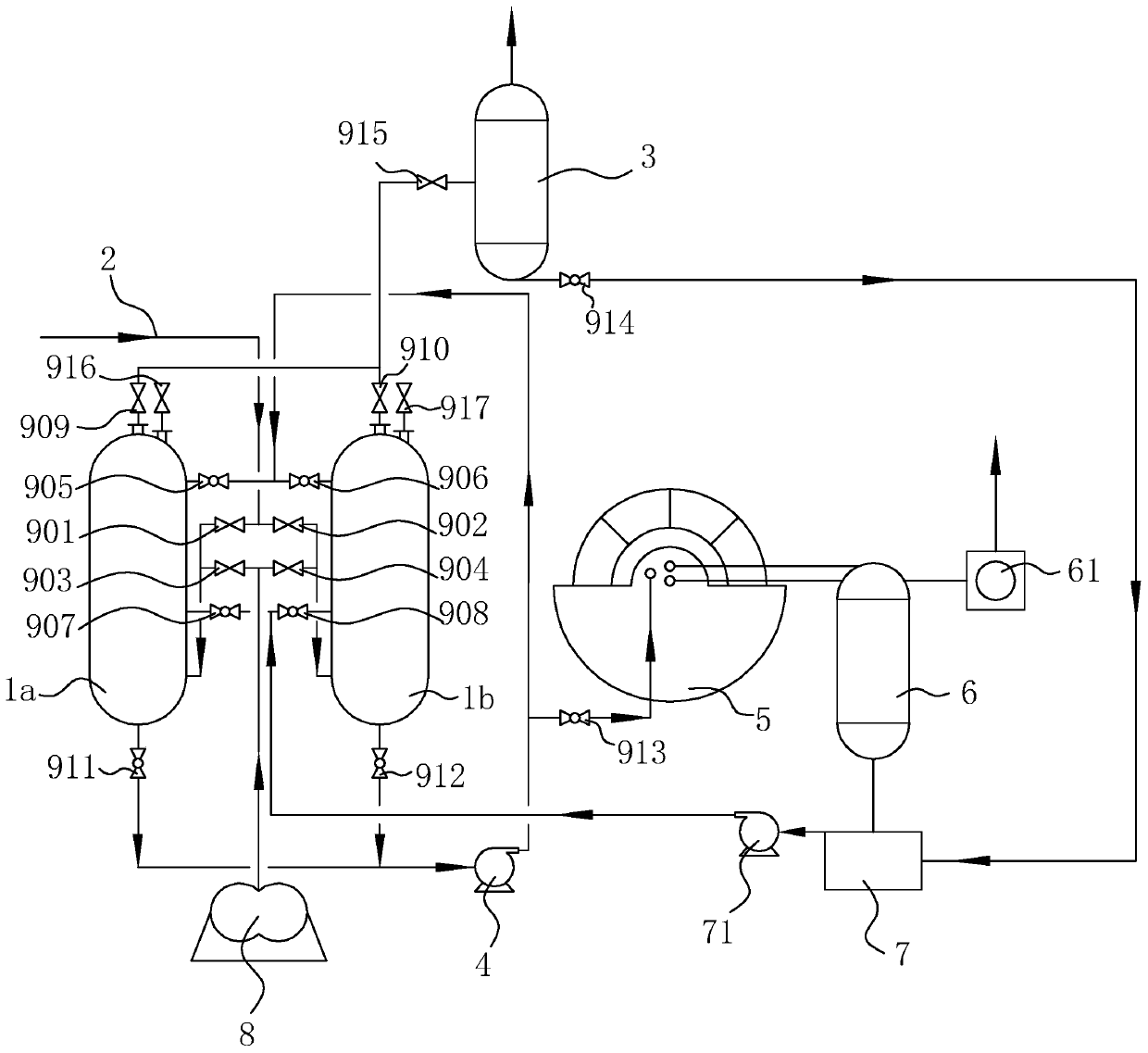

Method used

Image

Examples

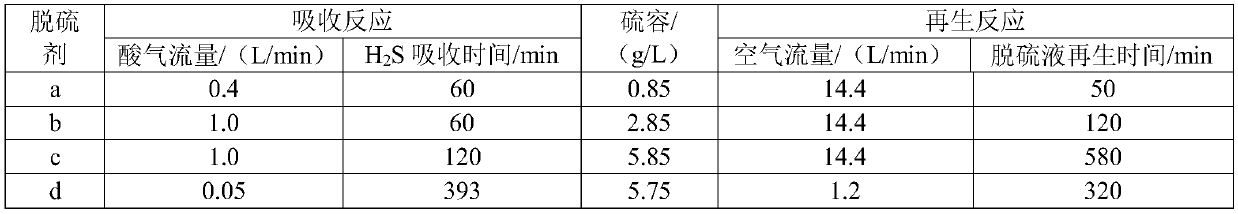

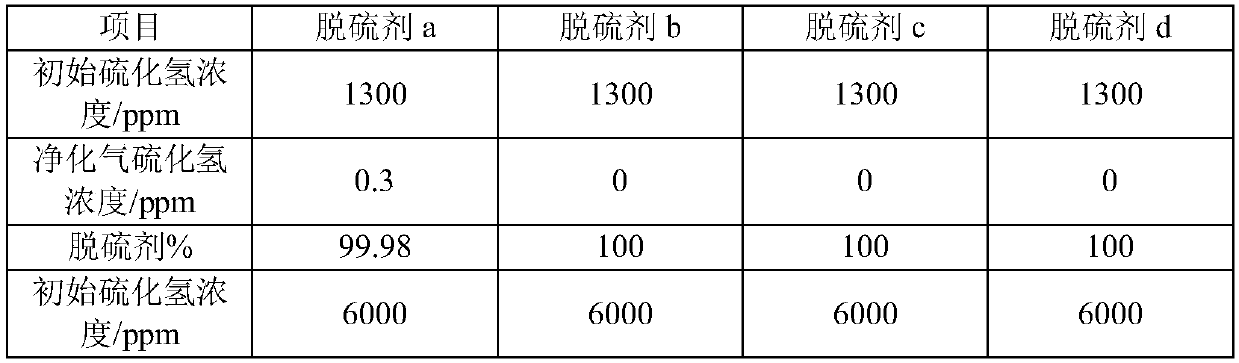

Embodiment 1

[0040] A preparation method of a high-capacity desulfurizer, comprising the steps of:

[0041] Step 1: chelating agent B, Fe(NO 3 ) 3 9H 2 O is mixed with water to obtain a complex iron catalyst, wherein the chelating agent B is HEDTA and sodium gluconate, the mol ratio of the two is 1: 0.25, and the mol ratio of chelating agent B and Fe element is 1.5: 1, and utilize NaOH regulates the pH value of complex iron catalyst to 9.5, and the complex iron catalyst that makes total iron concentration is 4.5wt%; Step 2: get complex iron catalyst 375g, chelating agent A 238g, sulfur wetting agent 72g and stabilizer 523g was mixed and diluted with water to 6000mL, wherein the diluted liquid was adjusted to a pH value of 9.5 by KOH to make desulfurizer a;

[0042] Among them, the chelating agent A is 620 chelating agent, which can be purchased from Zhejiang Jiayun Energy Technology Co., Ltd., the sulfur wetting agent is octylphenol polyoxyethylene ether with a polymerization degree of ...

Embodiment 2

[0044] A preparation method of a high-capacity desulfurizer, comprising the steps of:

[0045] Step 1: chelating agent B, FeCl 3 ·6H 2 O is mixed with water to obtain a complex iron catalyst, wherein the chelating agent B is EDTA and sodium gluconate, the mol ratio of the two is 1: 0.5, the mol ratio of chelating agent B and Fe element is 1: 1, and utilize Ammonia liquor regulates the pH value of complexed iron catalyst to 8.5, and the complexed iron catalyst that makes total iron concentration is 3wt%;

[0046] Step 2: Mix 1250g of chelated iron catalyst, 790g of chelating agent A, 152g of sulfur wetting agent and 1540g of stabilizer, and dilute to 6000mL with water, wherein the diluent is adjusted to pH 8.5 by sodium methoxide to make desulfurizer b.

[0047] Among them, the chelating agent A is 620 chelating agent, the sulfur wetting agent is dodecylphenol polyoxyethylene ether and nonyl polyoxyethylene ether mixed at a mass ratio of 1:1, and the stabilizer is potassium c...

Embodiment 3

[0049] A preparation method of a high-capacity desulfurizer, comprising the steps of:

[0050] Step 1: chelating agent B, Fe 2 SO 4 Mix with water to obtain a complex iron catalyst, wherein the chelating agent B is HEDP and sulfosalicylic acid, the molar ratio of the two is 1: 1, the mol ratio of the chelating agent B to the Fe element is 2: 1, and Utilize NaOH to adjust the pH value of complex iron catalyst to 7.5, make the complex iron catalyst that total iron concentration is 6wt%;

[0051] Step 2: Mix 2500g of complex iron catalyst, 1500g of chelating agent B, 114g of sulfur wetting agent and 105g of stabilizer, and dilute to 6000mL with water, wherein the diluent is adjusted to pH 6.5 with ammonia water to make desulfurizer c.

[0052] Wherein, the chelating agent A is 620 chelating agent, and the sulfur wetting agent is a small molecule alcohol, which is obtained by mixing ethanol and propanol with a volume ratio of 1:1, and the stabilizing agent is sodium sulfite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com