Workpiece with diamond/graphene composite lubricating film and preparation method thereof

A graphene composite, diamond thin film technology, applied in the field of materials, achieves the effects of strong bonding force, improved wear resistance, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

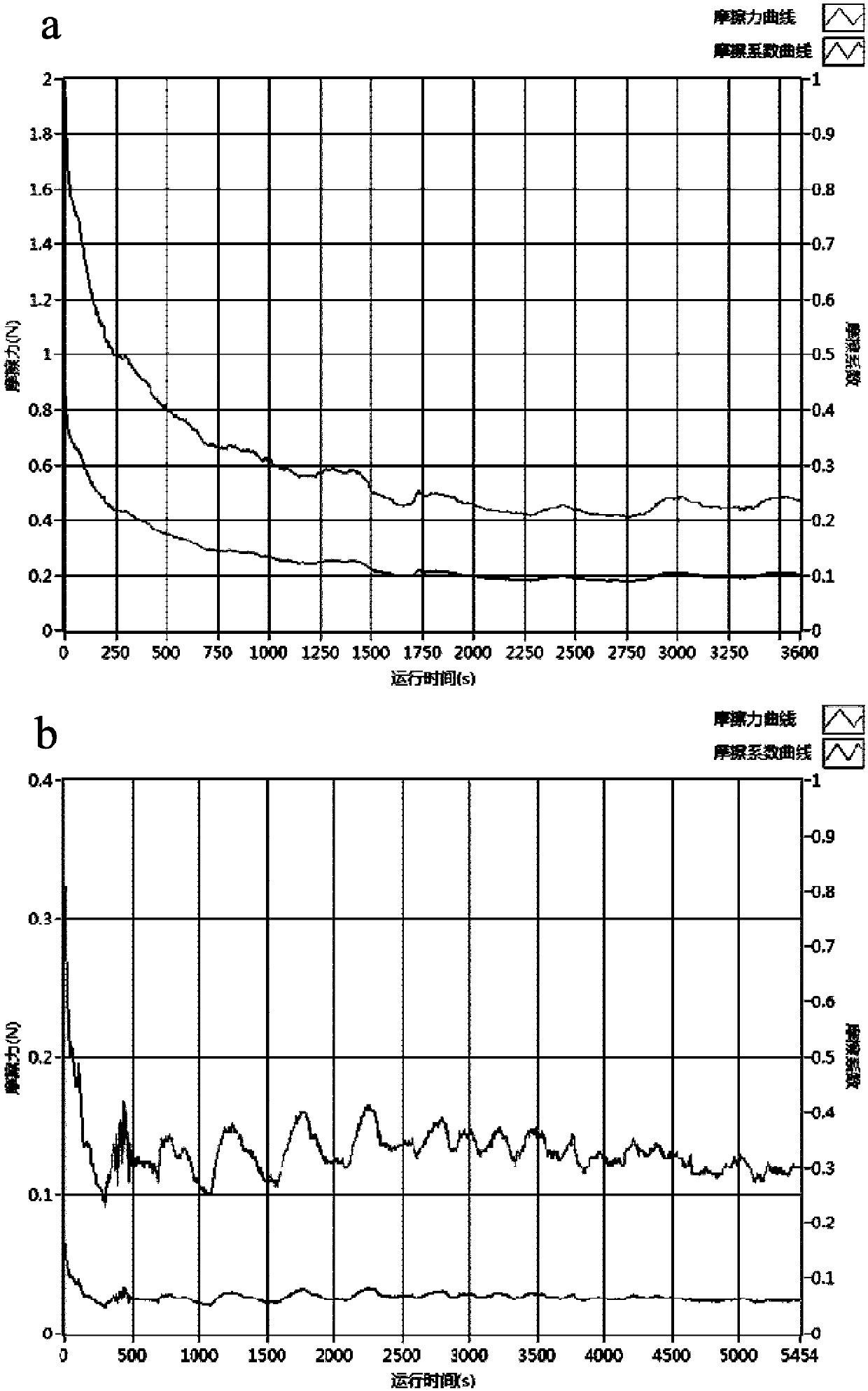

[0032] The second aspect of the present invention provides a method for preparing a workpiece provided with a diamond / graphene composite lubricating film, including:

[0033] Providing a workpiece body, depositing an ultra-nano diamond film on the workpiece body, and depositing a transition metal layer on the surface of the ultra-nano diamond film;

[0034] The workpiece body on which the transition metal layer and the ultra nano diamond film are deposited is placed in the cavity of a hot filament vapor deposition chamber for annealing treatment, and the transition metal in the transition metal layer catalyzes part of the carbon in the ultra nano diamond film The elements form a graphene layer, and a diamond / graphene composite lubricating film is prepared on the surface of the workpiece body, the annealing temperature is 1000-1300° C., and the annealing time is 1-3 min.

[0035] Optionally, the material of the workpiece body includes metal, silicon, hard alloy, silicon nitride or cer...

Embodiment 1

[0050] A method for preparing a workpiece provided with a diamond / graphene composite lubricating film, including:

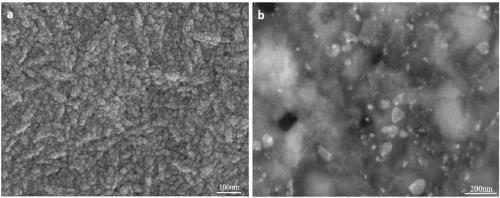

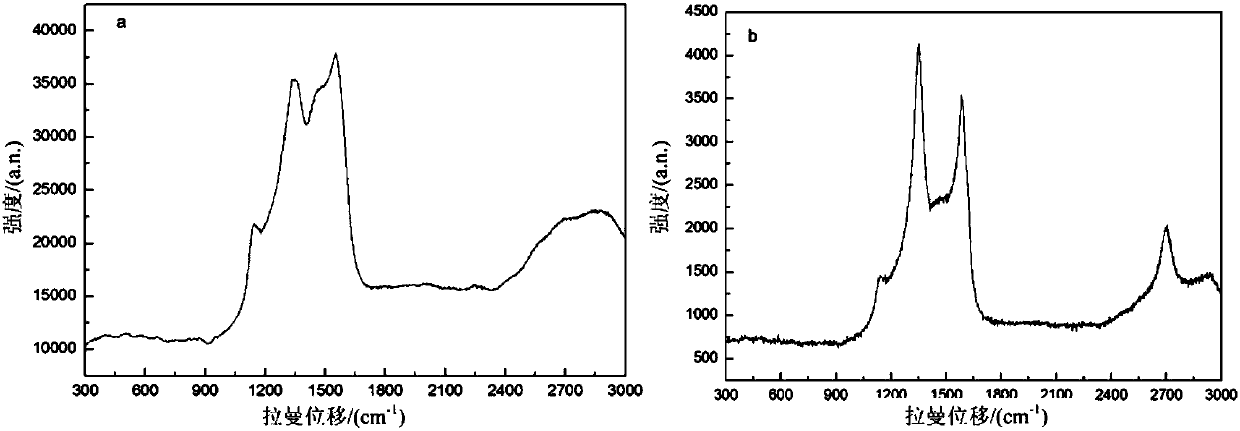

[0051] (1) Using hot filament vapor deposition method to deposit and grow diamond film on the substrate surface. Place the substrate material-silicon wafer in a beaker filled with acetone and deionized water for 10 min each ultrasonic cleaning to remove oil stains and other impurities attached to the sample surface; then place the cleaned substrate in the nano-diamond powder suspension Ultrasound for 30-45min. The average particle size of the diamond powder suspension is 5nm, which exists in the most dispersed form, and the Zeta potential is about ±50mV. Then place the processed substrate on the HFCVD substrate stage and vacuumize to 10 -5 Below Pa, the diamond film begins to nucleate and grow. The specific parameters of HFCVD work are as follows: the hot wire array is composed of 9 tantalum wires with a diameter of 0.5mm, the distance between the hot wire and the...

Embodiment 2

[0056] A method for preparing a workpiece provided with a diamond / graphene composite lubricating film, including:

[0057] Step (1) and step (2) are the same as in Example 1;

[0058] (3) Using hot filament vapor deposition equipment for rapid annealing to obtain graphene. Put the sample plated with a metallic nickel layer into the HFCVD cavity for rapid annealing. During the annealing process, the specific parameters of HFCVD work: the hot wire array consists of 9 tantalum wires with a diameter of 0.5mm, the distance between the hot wire and the sample surface is 8mm, the nitrogen / hydrogen flow rate: 425sccm / 75sccm, the total gas flow rate: 500sccm , Air pressure: 2800Pa, heating wire power: 5000W, heating sample temperature at 1200℃, after holding at 1200℃ for 2min, cooling to 300℃ at a rate of 30℃ / min, and then opening the hot filament vapor deposition chamber Body, cool the workpiece to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com