Novel plasma enhanced chemical vapor deposition (PECVD) coating technology

A process and new technology, applied in the field of new PECVD coating process, can solve the problems of increasing the surface recombination rate, surface damage, reducing the short-circuit current of the battery, etc., to reduce the recombination center, increase the electron-hole pair, and improve the short-circuit current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] PECVD coating is performed on the surface of polysilicon, and the process settings are as follows:

[0043] (1) Polysilicon feeding into the furnace: the temperature is 450°C, the nitrogen flow rate is 5000 sccm, and the time is 250s;

[0044] (2) Heating up in the furnace: the temperature is 450°C, the nitrogen flow rate is 5000 sccm, and the time is 550s;

[0045] (3) Ammonia purging: the temperature is controlled at 425° C., and the flow rate of ammonia gas of 5500 sccm is introduced for 65 seconds;

[0046] (4) Vacuum leak detection: the temperature is controlled at 420°C, and the furnace tube is pumped with a vacuum pump. The pressure reaches 100mTorr within 200s, and is maintained for 30-120s. Observe whether the pressure exceeds 100mTorr;

[0047] (5) Pre-deposition: input ammonia gas 5000sccm, silane 550sccm, turn on the radio frequency generator, the radio frequency power is 5000w, set the time for 15s, then turn off the radio frequency, and the gas input stop...

Embodiment 2

[0056] (1) Density test of PECVD film on silicon wafer

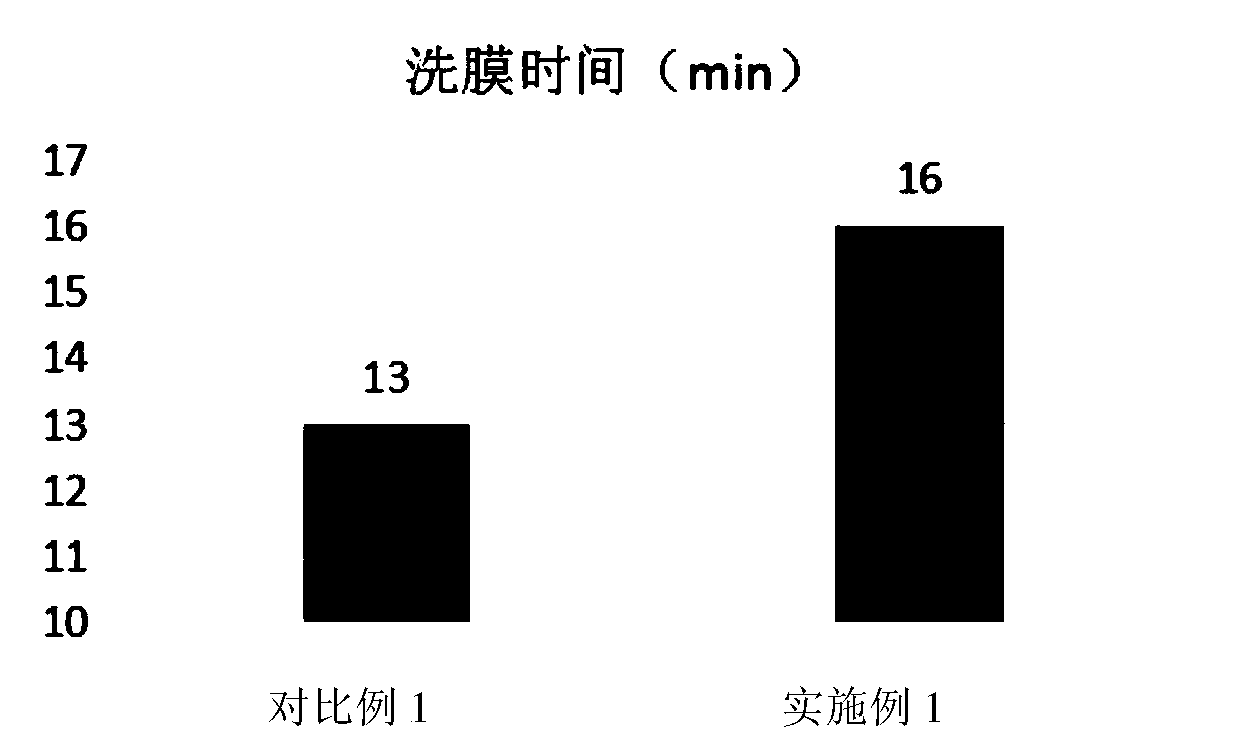

[0057] The compactness of the PECVD film is judged by the pickling time, randomly select 25 silicon wafers produced in Comparative Example 1 and 25 silicon wafers produced in Example 1, and put them into a 15% hydrofluoric acid solution together. In the utensil, count the time when the PECVD film is soaked. Such as figure 1 , the film washing time of embodiment 1 is 3 minutes more than the film washing time of comparative example 1, illustrates that the PECVD film compactness of embodiment 1 is higher than the PECVD film of comparative example 1, adopts technology of the present invention to coat PECVD film to silicon chip , the density of its PECVD film is better.

[0058] (2) Electrical performance test of the battery sheet prepared in Comparative Example 1 and Example 1

[0059] The silicon wafers produced in Comparative Example 1 and Example 1 are sent to the screen section, and are dried by the screen printing ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com