High-reliability NIP structure mesa type photodiode and manufacturing method thereof

A technology of photodiode and manufacturing method, applied in sustainable manufacturing/processing, circuits, electrical components, etc., can solve problems such as complex surface protection, achieve the effect of suppressing leakage current and edge breakdown, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

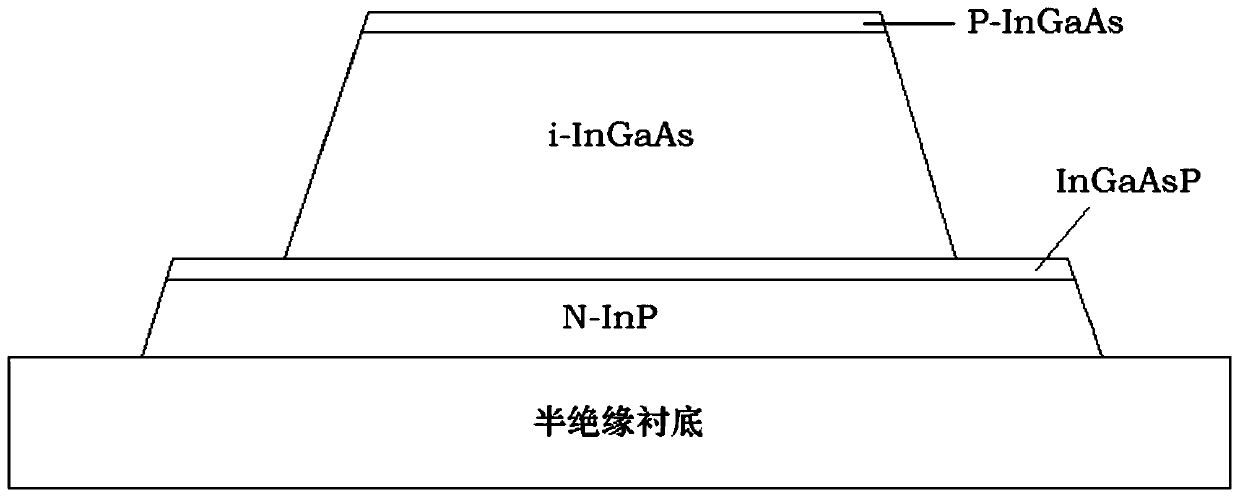

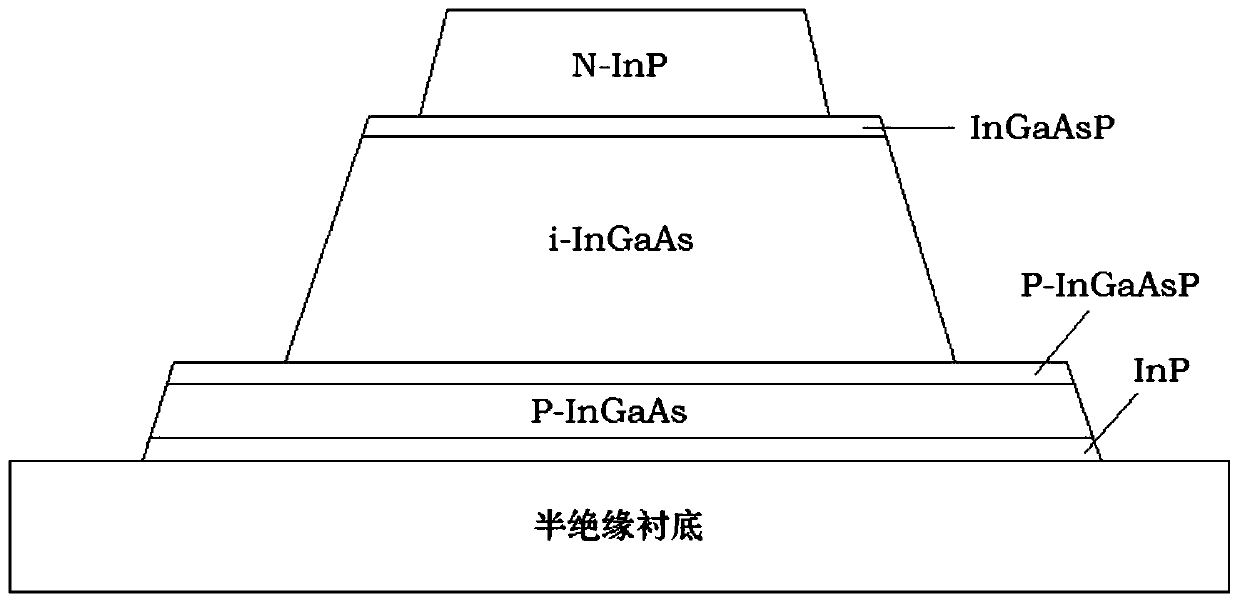

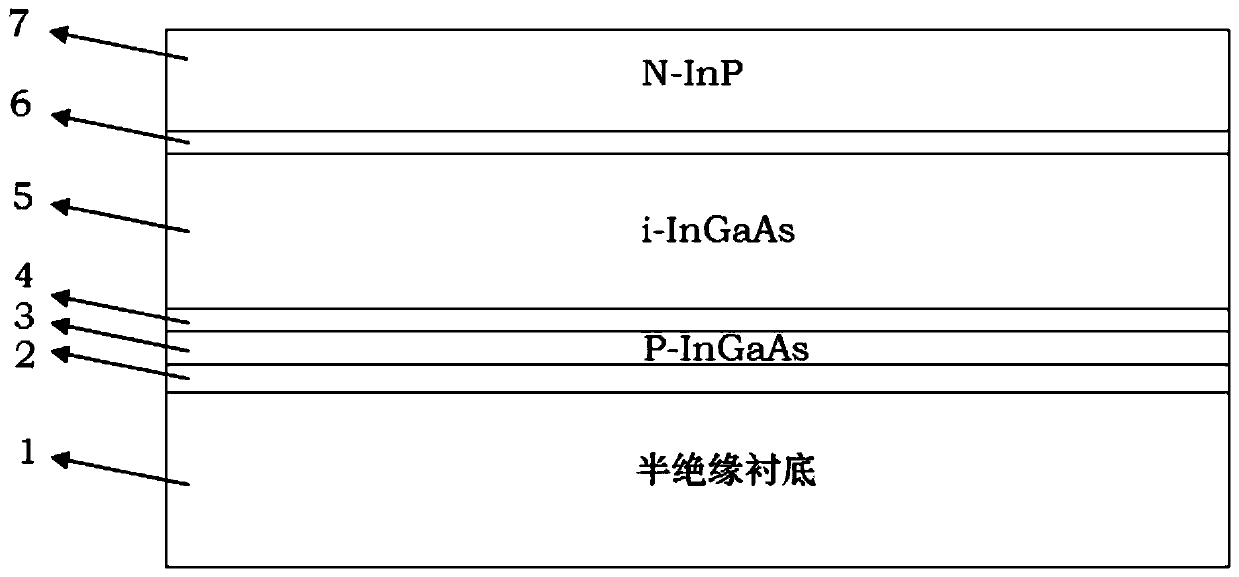

[0034] As a specific embodiment, the present invention will be described in detail below in conjunction with the accompanying drawings and process flow. In this embodiment, the chip structure epitaxial material is grown on a semi-insulating substrate by metal organic chemical vapor deposition (MOCVD) or molecular beam epitaxy (MBE). Bottom 1, that is, on the InP substrate, the structure can be as follows figure 2 and image 3 As shown, in order:

[0035] 1) buffer layer 2

[0036] A weak n-type indium phosphide (InP) buffer layer is used, and its carrier concentration is 1×10 15 cm -3 , with a thickness of 0.1-0.5 μm;

[0037] 2) P-type contact layer 3

[0038] Use P-type InGaAs contact layer, doped with carbon, carrier concentration ≥ 1×10 18 cm -3 , with a thickness of 0.1-0.5 μm.

[0039] 3) Barrier layer 4

[0040] P-type indium gallium arsenide phosphide (InGaAsP) barrier layer, doping concentration ≥ 1×10 18 cm -3 , and its growth thickness is 0.01-0.2 micron...

Embodiment 2

[0048] The manufacturing process of the present embodiment includes the following steps:

[0049] 1) Deposition on epitaxial material by plasma enhanced chemical vapor deposition (PECVD) A silicon nitride (SiNx) dielectric film is used to define the mesa region of the first layer through a photolithography process.

[0050]2) The first layer of mesa is defined by dry etching or wet etching. Dry etching can use inductively coupled plasma etching (ICP) or reactive ion etching (RIE); wet etching can use For acid series, acid oxygen series, and bromine series etching solutions, the etching or etching depth must reach the InGaAsP gradient layer.

[0051] 3) Using the photoresist as a mask to define the mesa region of the second layer through a photolithography process.

[0052] 4) The second mesa is defined by dry etching or wet etching. Dry etching can be inductively coupled plasma etching (ICP) or reactive ion etching (RIE); wet etching can use For acid series, acid oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com