Fireproof paint based on zirconium phosphate and methacrylic acid composite modified acrylate core-shell emulsion and preparation method of fireproof paint

A technology of methacrylic acid and compound modification, which is applied in the direction of fireproof coatings, coatings, etc., can solve the problems of poor water resistance and stain resistance, poor aging resistance and oxidation resistance, and is not suitable for wide application. The layer is firm, promotes the thermal oxidation crosslinking reaction, and is not easy to break through the flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

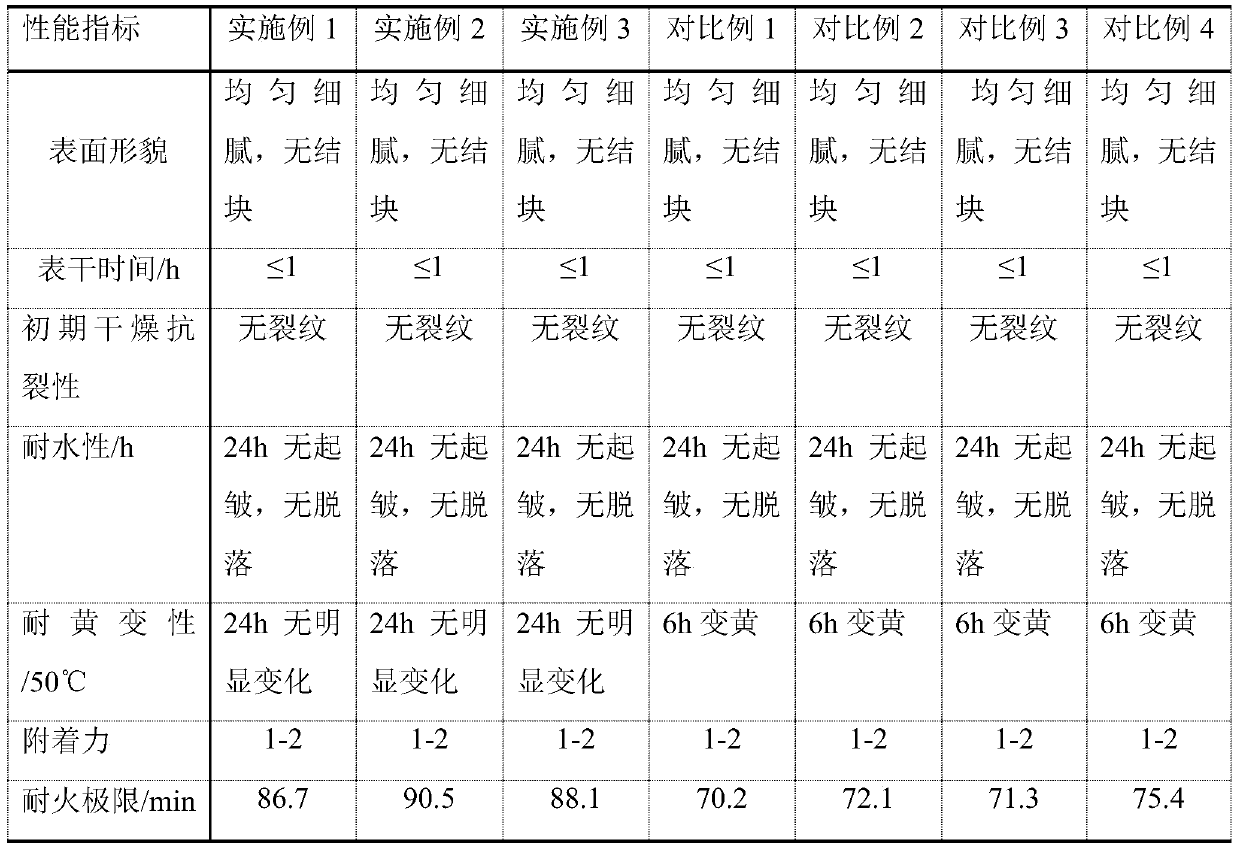

Examples

Embodiment 1

[0046] A fireproof coating based on zirconium phosphate and methacrylic acid composite modified acrylate core-shell emulsion, each component and its mass percentage are: zirconium phosphate and methacrylic acid composite modified acrylate core-shell emulsion 20%, poly Ammonium phosphate 36%, pentaerythritol 12%, melamine 12%, titanium dioxide 3%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 15%, and its preparation method includes The following steps:

[0047] 1) Weigh the raw materials according to the above proportioning requirements;

[0048] 2) Grind the weighed ammonium polyphosphate, pentaerythritol, melamine, titanium dioxide, and hydroxyethyl cellulose into powder, then add water to fully grind and mix evenly; then add defoamer and dispersant, and continue to grind fully;

[0049] 3) Finally, zirconium phosphate and methacrylic acid composite modified acrylate core-shell emulsion and n-octanol are added and thoroughly ground and m...

Embodiment 2

[0051] A fireproof coating based on zirconium phosphate and methacrylic acid composite modified acrylate core-shell emulsion, each component and its mass percentage are: zirconium phosphate and methacrylic acid composite modified acrylate core-shell emulsion 25%, poly Ammonium phosphate 36%, pentaerythritol 12%, melamine 12%, titanium dioxide 3%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 10%, and its preparation steps are the same as Example 1.

Embodiment 3

[0053] A fireproof coating based on zirconium phosphate and methacrylic acid composite modified acrylate core-shell emulsion, each component and its mass percentage are: 30% of zirconium phosphate and methacrylic acid composite modified acrylate core-shell emulsion, poly Ammonium phosphate 36%, pentaerythritol 12%, melamine 12%, titanium dioxide 3%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 5%, and its preparation steps are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com