Adjustable protein-based flexible strain sensor and preparation method and application thereof

A strain sensor and protein technology, applied in the field of biomaterials and mechanical sensors, can solve the problems of ignoring the fit, comfort, degradability and biocompatibility of flexible sensors, and the sensor sensitivity and adjustability are not ideal. Easy to fit on the skin, good flexibility, good comfort results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

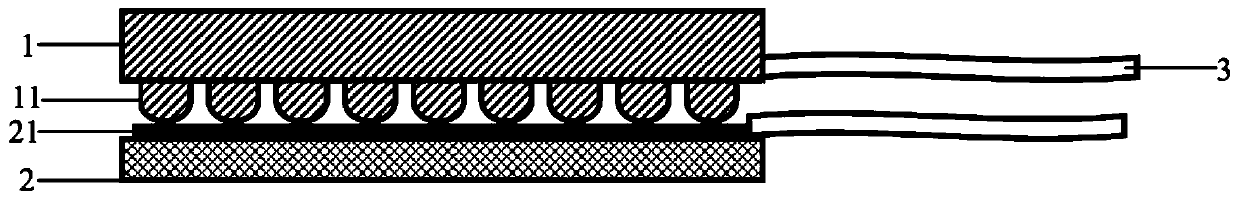

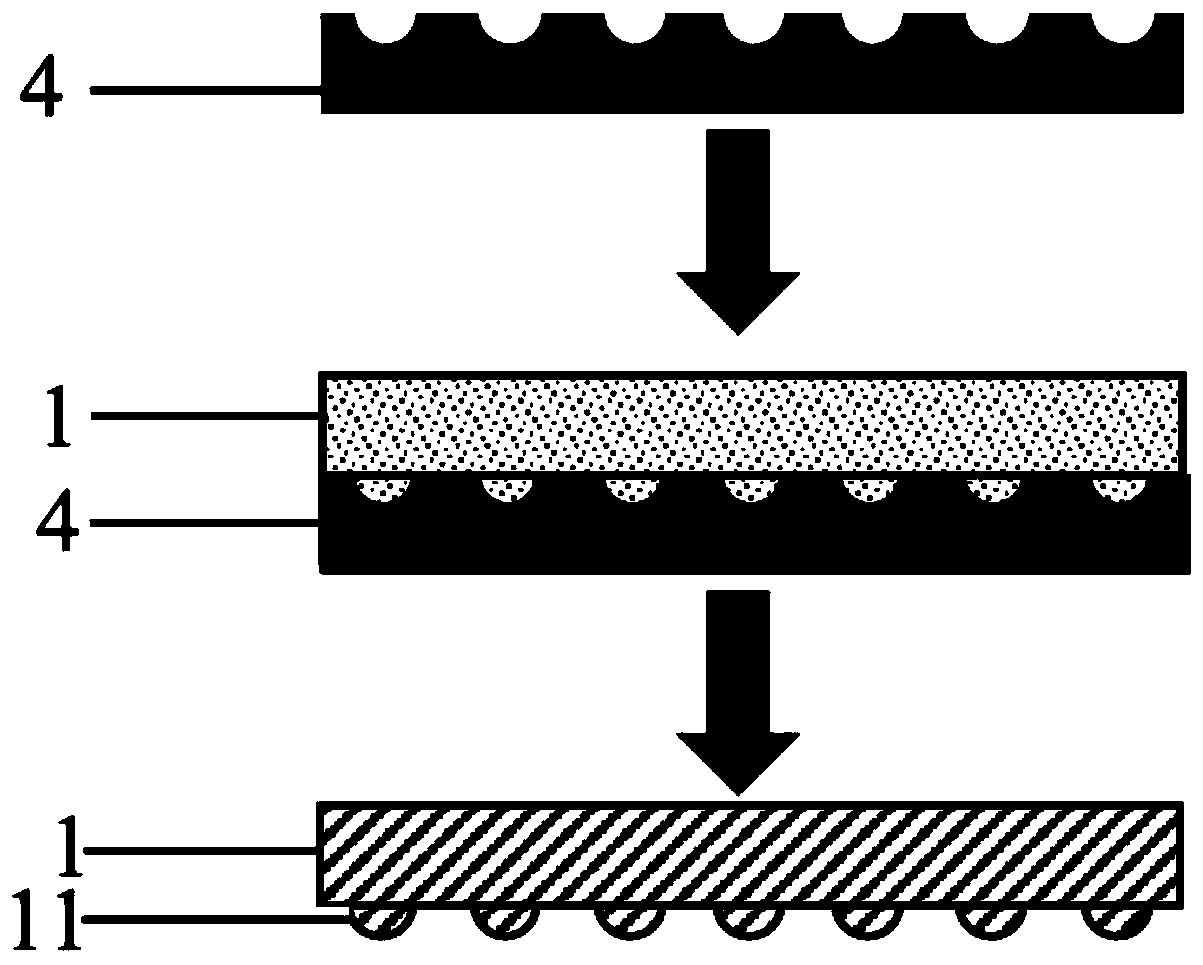

[0038] The present invention also proposes a method for preparing the above-mentioned adjustable protein-based flexible strain sensor, comprising the following steps:

[0039]S1, pouring PDMS into a template with arrayed protrusions, and obtaining a negative template 4 after solidification.

[0040] Further, in step S1, the template is selected from one of metal microstructure templates, silicon microstructure templates, ceramic microstructure templates or polymer microstructure templates; wherein the metal microstructure templates are selected from aluminum One of formwork, stainless steel formwork and titanium formwork.

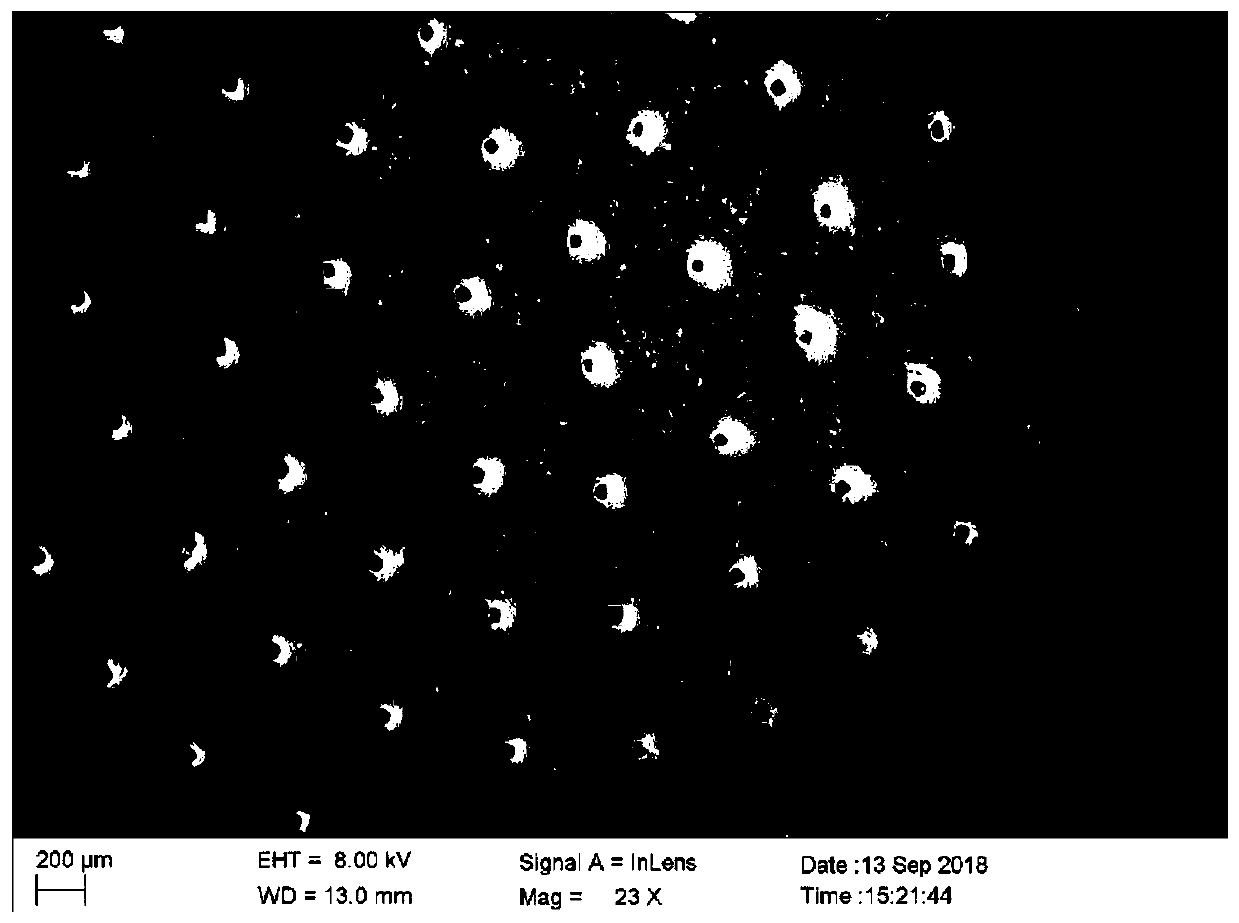

[0041] In a preferred embodiment of the present invention, the step of the negative template 4 is: first pour PDMS into a metal microstructure template with hemispherical or semiconical protrusions, wherein the diameter of the hemispherical shape is 70-90 μm, Take it out after being solidified, and you can get the female template 4 with hemispherical or se...

Embodiment 1

[0057] The embodiment of the present invention provides an adjustable protein-based flexible strain sensor, which is prepared according to the following steps:

[0058] (1) Prepare the negative template: first pour PDMS into the aluminum alloy microstructure template with hemispherical or semi-conical protrusions, wherein the hemispherical diameter is 80 μm, take it out after solidification, and obtain hemispherical miniature elastic protrusions negative template.

[0059] (2) Prepare the upper plate:

[0060] 1) Preparation of silk fibroin solution: After removing impurities from natural silk cocoons, take 15g of silk cocoons, soak them in warm water for 30 minutes, repeat 3 times, heat the silk cocoons with 15g of sodium bicarbonate and 3L of deionized water to boiling, and degumming for 30 minutes. Then put it into 4L of distilled water and stir it with magnetic force for 30 minutes to obtain the degummed silk, and place it at 60° C. to dry to obtain the silk fibroin fiber...

Embodiment 2

[0069] The embodiment of the present invention provides an adjustable protein-based flexible strain sensor, which is different from Embodiment 1 in that:

[0070] When preparing the upper plate in step (2), weigh 0.95g sodium sulfide nonahydrate, 21g urea, 0.4g sodium lauryl sulfate and 5g washed wool in step 2) to form a 50ml mixed solution , placed at 60°C for 8 hours to obtain an initial solution. The initial solution was placed in a dialysis bag and dialyzed with deionized water for 72 hours, and the water was changed every hour to obtain a wool keratin solution. The horn wool keratin extracted in this way has longer molecular chains.

[0071] When preparing the upper pole plate in step (2), in step 3), after mixing the silk fibroin solution and the wool keratin solution, adding the carbon nanotube solution to obtain a mixed solution. Wherein, the mass ratio of silk fibroin and wool keratin in the mixed solution is 9:1, and the mass fraction of carbon nanotubes is 30%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com