Hybrid supercapacitor based on graphite cathode and zinc anode

A supercapacitor and hybrid technology, which is applied in the field of electrochemical energy storage, can solve the problems of low specific capacity and energy density of hybrid capacitors, and achieve the effects of reducing material costs, high safety, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

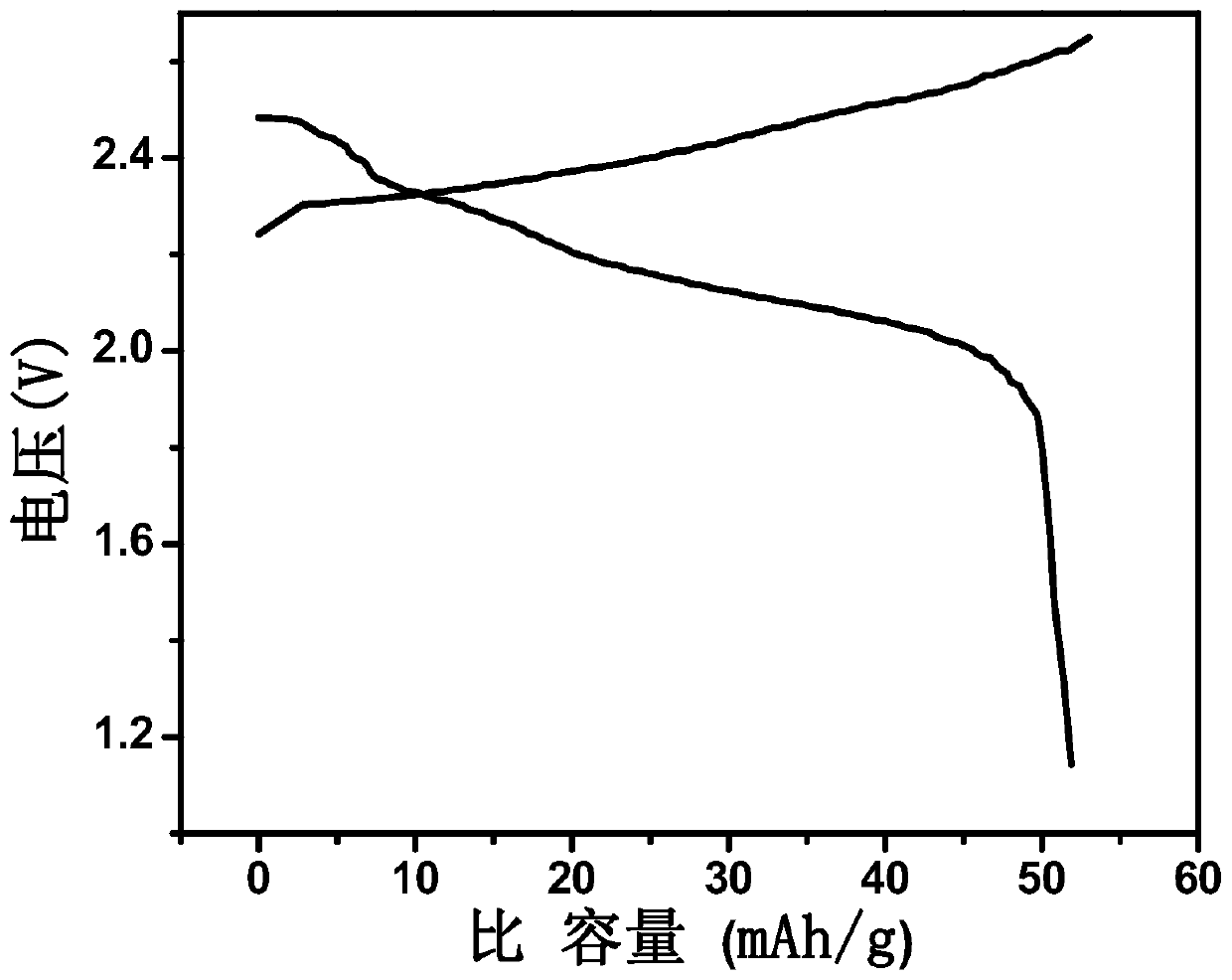

[0037] Mix natural graphite and binder styrene-butadiene rubber in a mass ratio of 9:1, use a scraper to scrape the mixed slurry on the cleaned aluminum foil positive current collector and scrape a film with a thickness of 150 μm, and cut it into diameters after drying. It is a 12mm positive pole piece. The negative pole piece is made of zinc foil with a diameter of 12mm. 1mol / L concentration of Zn(CF 3 SO 3 ) 2 / acetonitrile solution was used as electrolyte, glass fiber with a diameter of 16.5 mm was used as separator, and 150 μL of electrolyte was added dropwise on the separator. The battery packaging machine is used for packaging, and from bottom to top are the negative electrode shell, the negative electrode piece, the separator, the positive electrode piece, the gasket, the shrapnel, and the positive electrode shell. The assembled hybrid supercapacitors were left to stand at room temperature for 2 hours, and then the electrochemical performance was tested with a blue ...

Embodiment 2

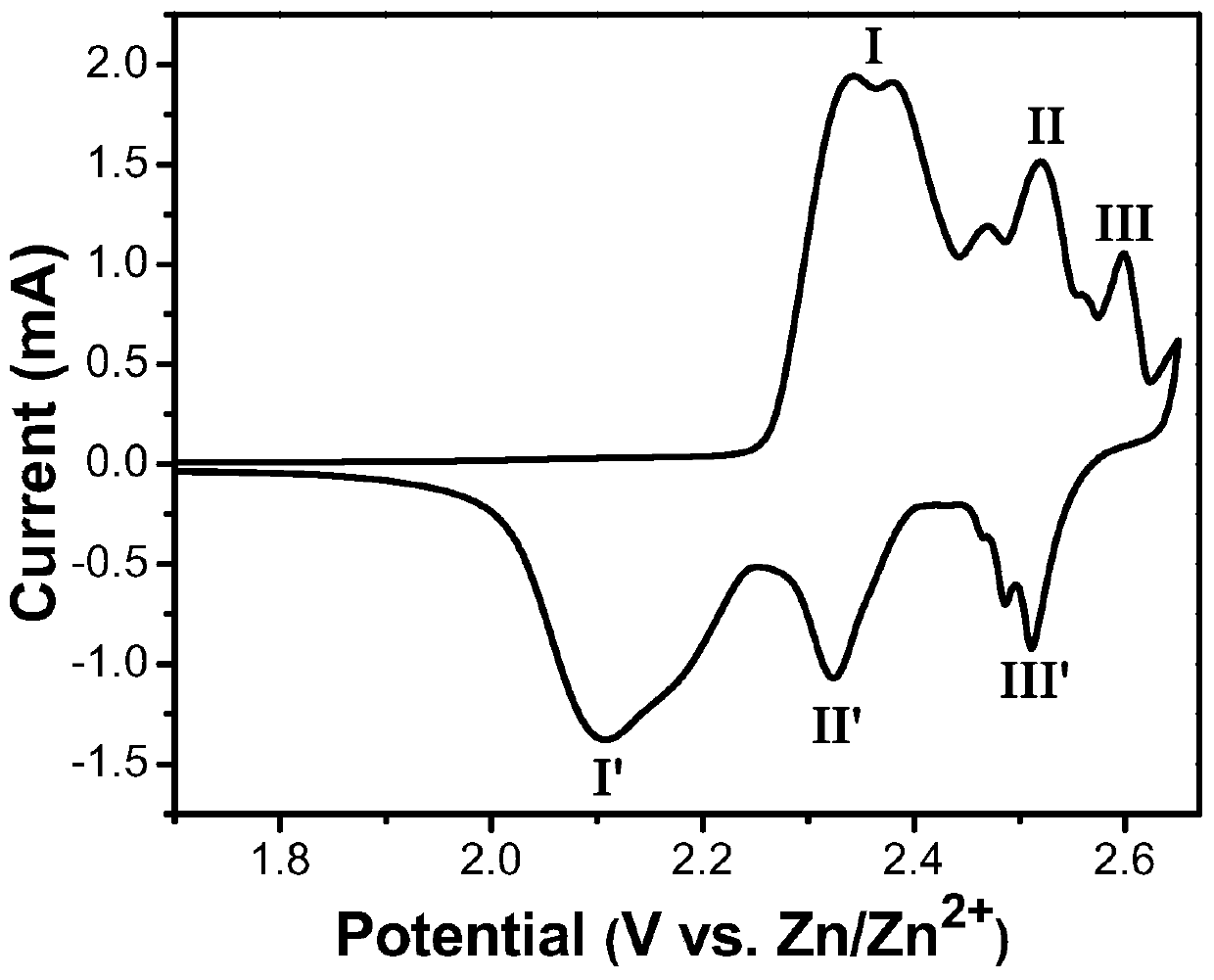

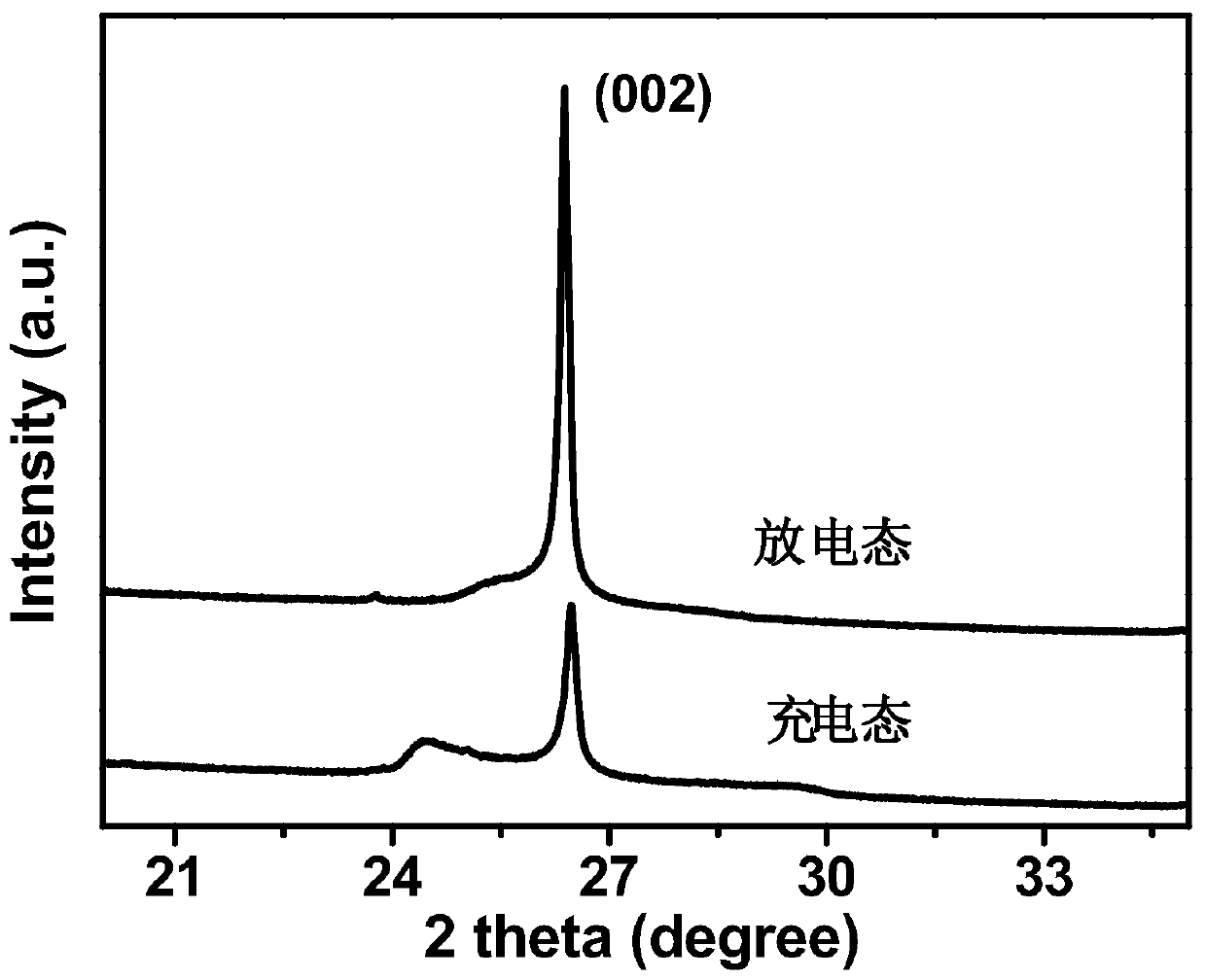

[0039] Mix artificial graphite and binder polyvinylidene fluoride in a mass ratio of 95:5, use a scraper to scrape the mixed slurry on the cleaned aluminum foil positive current collector and scrape a film with a thickness of 150 μm, and cut it after drying. A positive pole piece with a diameter of 12mm. The negative pole piece is a zinc piece with a diameter of 12mm. 0.2mol / L concentration of ZnSO 4 / acetonitrile solution was used as electrolyte, glass fiber with a diameter of 16.5 mm was used as separator, and 150 μL of electrolyte was added dropwise on the separator. The battery packaging machine is used for packaging, and from bottom to top are the negative electrode shell, the negative electrode piece, the separator, the positive electrode piece, the gasket, the shrapnel, and the positive electrode shell. The assembled hybrid supercapacitor was allowed to stand at room temperature for 2 hours to obtain the hybrid supercapacitor described in this example. A cyclic volta...

Embodiment 3

[0041] Mix artificial graphite, binder polytetrafluoroethylene and conductive agent acetylene black in a mass ratio of 85:10:5, and use a scraper to scrape the mixed slurry on the cleaned aluminum foil cathode current collector with a thickness of 150μm. The membrane was dried and cut into positive pole pieces with a diameter of 12 mm. The negative pole piece is made of zinc foil with a diameter of 12mm. 2mol / L concentration of ZnCl 2 / Propylene carbonate solution was used as electrolyte, glass fiber with a diameter of 16.5 mm was used as separator, and 150 μL of electrolyte was dropped on the separator. The battery packaging machine is used for packaging, and from bottom to top are the negative electrode shell, the negative electrode piece, the separator, the positive electrode piece, the gasket, the shrapnel, and the positive electrode shell. The assembled hybrid supercapacitor was allowed to stand at room temperature for 2 hours to obtain the hybrid supercapacitor descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com