an α-mno 2 @δ-mno 2 Preparation method and application of supercapacitor electrode material

A technology for supercapacitors and electrode materials, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc. uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

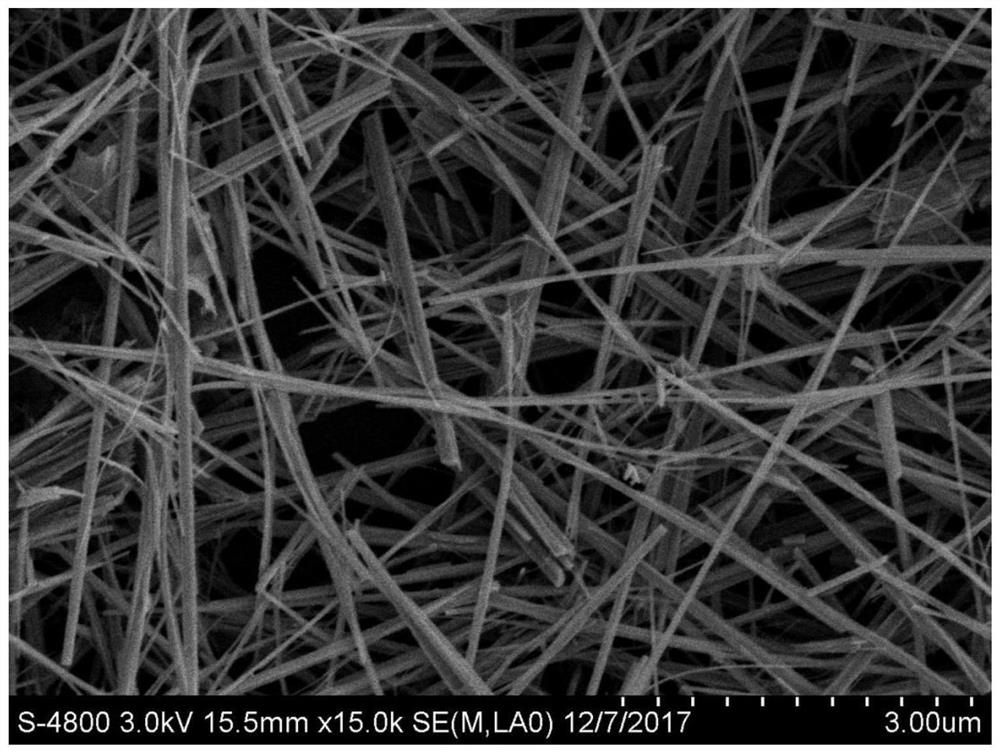

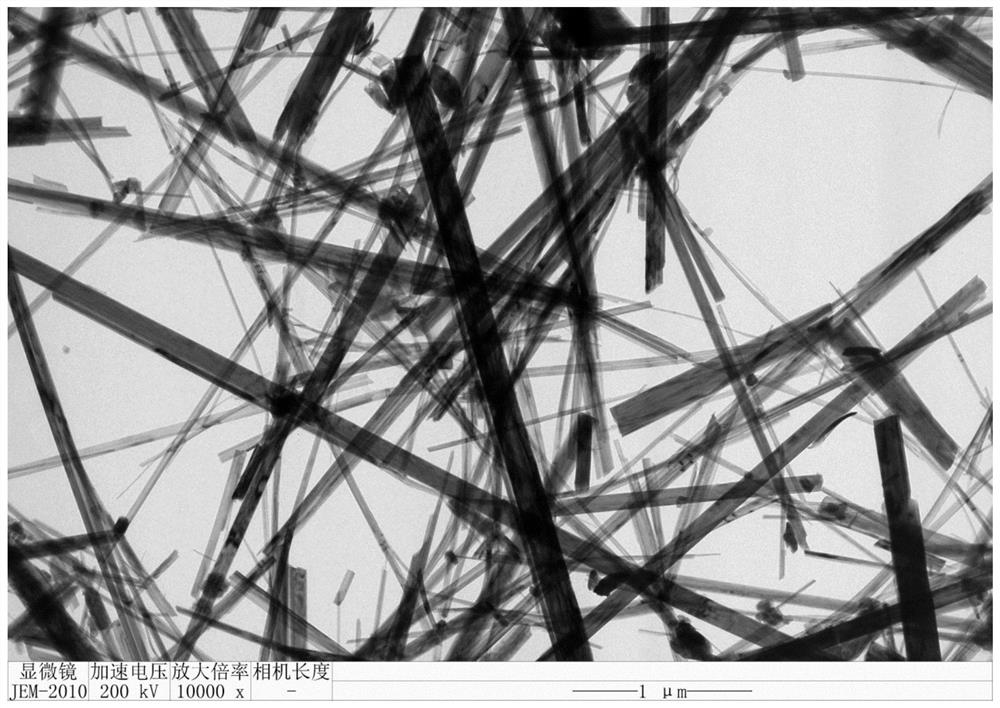

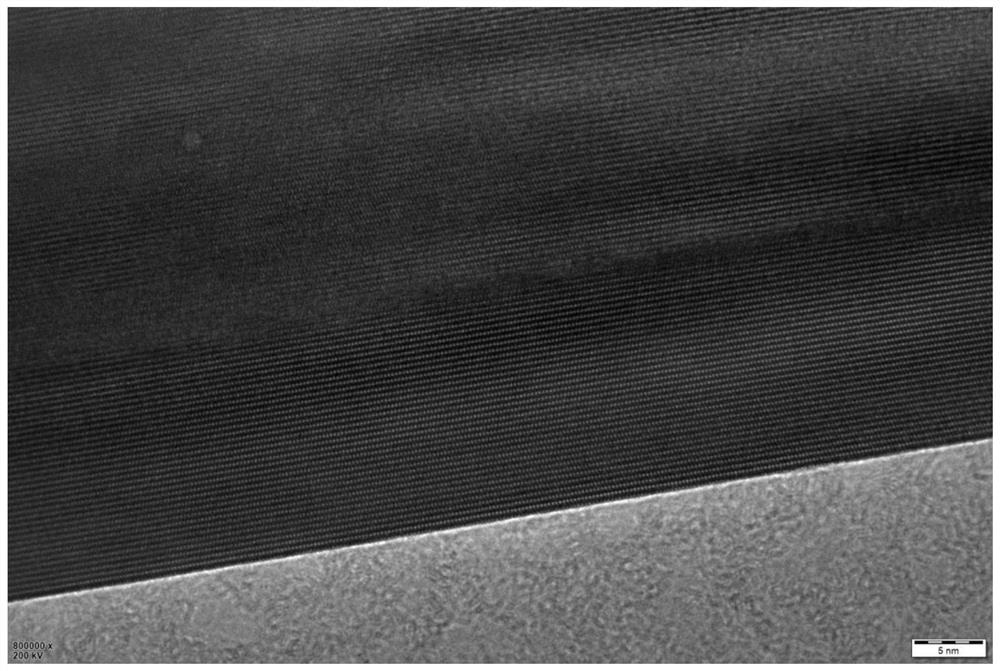

[0031]1. Weigh potassium permanganate (KMnO) with a molar ratio of 1:3 (1.5mmol: 4.5mmol)4) And manganese carbonate (MnCO3), add deionized water, and stir at room temperature for 30 min. Weigh 1mmol of cobalt salt, add it to the mixed solution, stir it evenly, and sonicate it for 20min at room temperature. The mixed solution was transferred to a polytetrafluoroethylene reactor and reacted at 100°C for 8 hours. After the reaction is over, cool to room temperature, centrifuge with water and ethanol several times, and dry, and the product obtained is α-MnO2. Fromfigure 1 It can be seen that the prepared α-MnO2The length of the nanowires is uniform.figure 2 As you can see, α-MnO2The diameter of the nanowire is less than 300 nm.image 3 The uniform lattice fringe indicates that the product is a single-phase material, which is different from α-MnO2The experimental results of nanowire single-phase materials are consistent. FromFigure 4 It can be seen that the crystal type shows α type MnO2....

Embodiment 2

[0037]1. Weigh potassium permanganate (KMnO) with a molar ratio of 1:3 (1.5mmol: 4.5mmol)4) And manganese carbonate (MnCO3), add deionized water, and stir at room temperature for 30 min. Weigh 3mmol of cobalt salt, add it to the mixed solution, further stir it evenly, and ultrasound for 20min at room temperature. The mixed solution was transferred to a polytetrafluoroethylene reactor and reacted at 110°C for 7 hours. After the reaction is over, cool to room temperature, centrifuge with water and ethanol several times, and dry, and the product obtained is α-MnO2. FromFigure 6 It can be seen that with the increase of cobalt salt doping, α-MnO2The nanowires began to bend. FromFigure 7 It can be seen that the CV curve presents a similar rectangular shape, indicating that the material has good electrochemical properties.Picture 8 After calculation, α-MnO2The specific capacitance of the nanowire is about 150F g-1.

[0038]2. Weigh potassium permanganate (KMnO) with a molar ratio of 1:3 (1.5m...

Embodiment 3

[0040]1. Weigh potassium permanganate (KMnO) with a molar ratio of 1:3 (1.5mmol: 4.5mmol)4) And manganese carbonate (MnCO3), add deionized water, and stir for 30 min at room temperature. Weigh 1mmol of cobalt salt, add it to the mixed solution, stir it evenly, and sonicate it for 20min at room temperature. The mixed solution was transferred to a polytetrafluoroethylene reactor and reacted at 120°C for 6 hours. After the reaction is over, cool to room temperature, centrifuge with water and ethanol several times, and dry, and the product obtained is α-MnO2.

[0041]2. Weigh potassium permanganate (KMnO) with a molar ratio of 1:3 (1.5mmol: 4.5mmol)4) And manganese carbonate (MnCO3), add deionized water, and stir for 30 min at room temperature. The α-MnO obtained in step (1)2Transfer to the mixed solution, further stir evenly, and ultrasound for 30 min at room temperature. The mixed solution was transferred to a polytetrafluoroethylene reactor and reacted at 120°C for 6 hours. After the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com