Lithium-sulfur battery, preparation method thereof and positive electrode material

A lithium-sulfur battery and cathode material technology, which is applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of high price, easy shedding of active materials, and decreased bonding performance, and achieves stable battery structure. The effect of improving ion conduction efficiency and stable bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

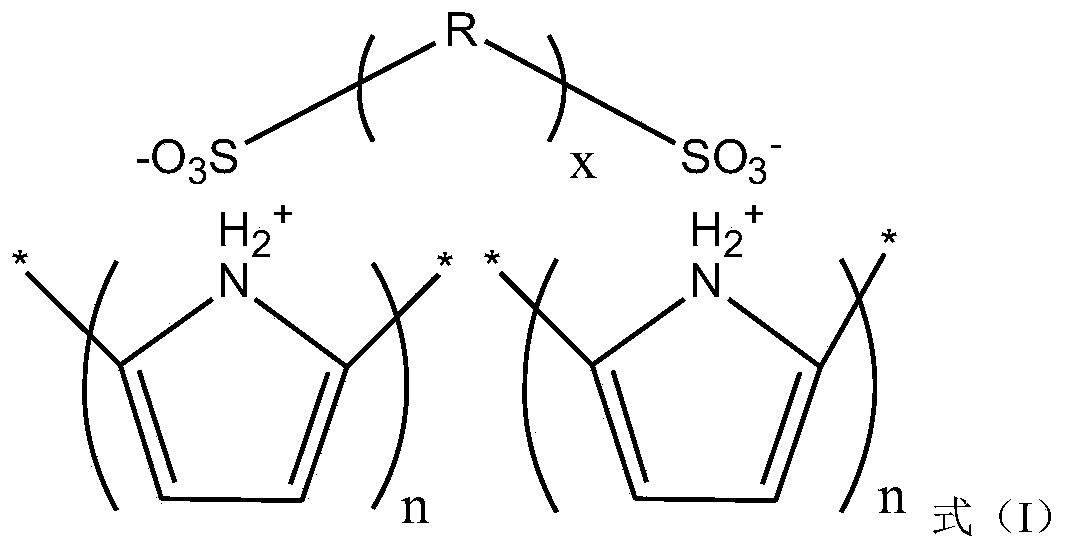

[0081] Embodiment 1: prepare binding agent

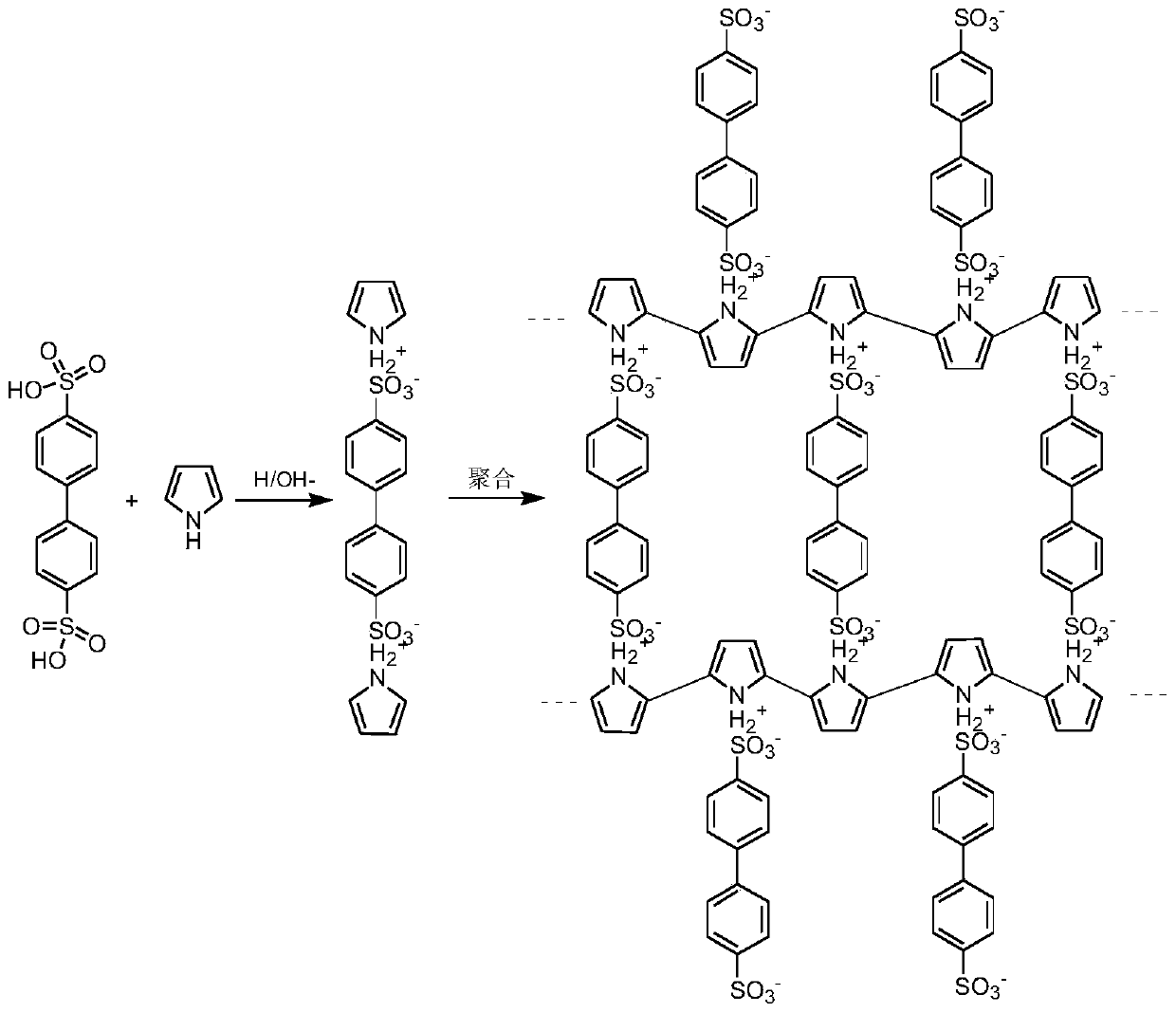

[0082] Add 100mg of polyacrylic acid to 5ml of deionized water, stir for 12h, add 22.8mg of ammonium persulfate and stir for 30min to obtain solution A; add 15.7mg of 4,4'-biphenyldisulfonic acid into another glass bottle equipped with magnetic stirring , add 5ml of deionized water until completely dissolved, add 10μl of pyrrole at 0°C, stir for 2h, mark the link between 4,4-biphenyldisulfonic acid and pyrrole as solution B, then add solution B to solution A, at 0 Stirring at ℃ for 12 hours, the stirring rate is 500rpm, so that the 4,4-biphenyldisulfonic acid-linked pyrrole is polymerized and dispersed in the polyacrylic acid to form a polymer network structure.

Embodiment 2

[0083] Embodiment 2: preparation binder

[0084] Add 125mg of polyacrylic acid to 5ml of deionized water, stir for 12h, add 23.8mg of sodium persulfate and stir for 1h to obtain solution A; add 15.7mg of 4,4'-biphenyl disulfonic acid into another glass bottle equipped with magnetic stirring , add 5ml of deionized water until completely dissolved, add 10μl of pyrrole at 0°C, stir for 2h, mark the link between 4,4'-biphenyldisulfonic acid and pyrrole as solution B, then add solution B to solution A, in Stir at 0° C. for 24 hours, and the stirring rate is 600 rpm, so that the 4,4′-biphenyldisulfonic acid-linked pyrrole is polymerized and dispersed in the polyacrylic acid to form a polymer network structure.

Embodiment 3

[0085] Embodiment 3: preparation binder

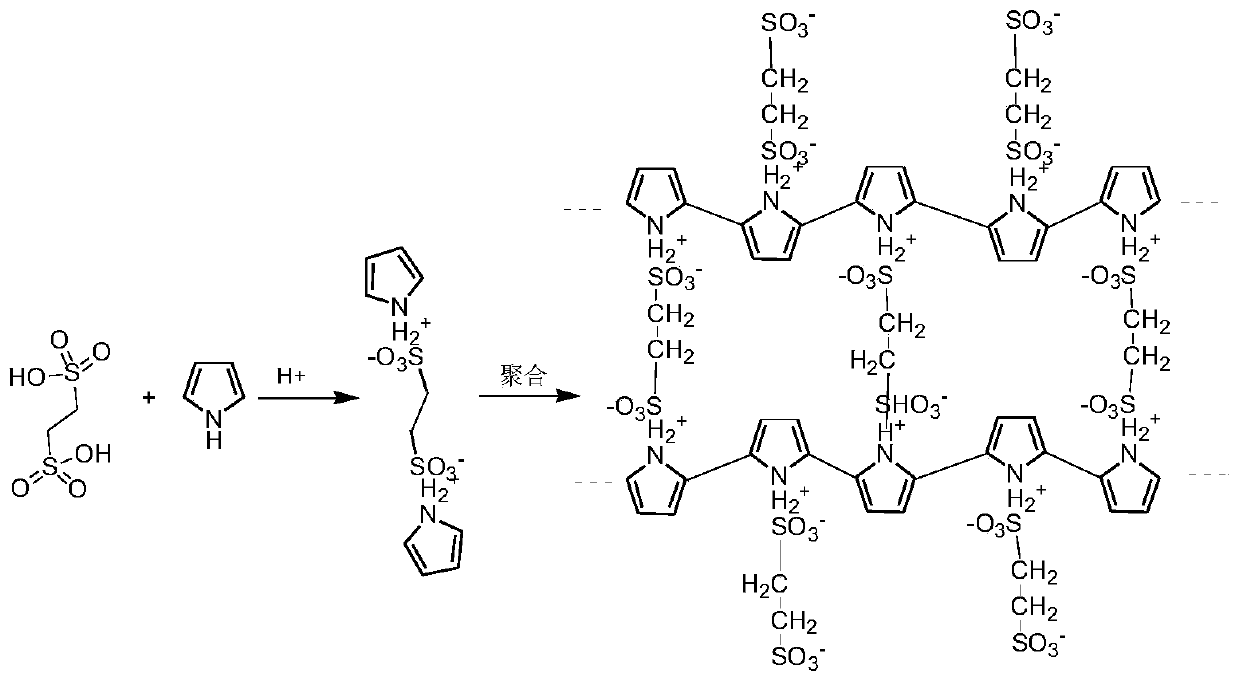

[0086] Add 50mg of polyacrylic acid to 5ml of deionized water, stir for 12h, add 27.0mg of potassium persulfate and stir for 1h to obtain solution A; add 9.5mg of 1,2-ethanedisulfonic acid to another glass bottle equipped with magnetic stirring, add 5ml of deionized water until completely dissolved, add 10μl of pyrrole at 0°C, stir for 2h, mark the connection of 4,4'-biphenyl disulfonic acid with pyrrole as solution B, then add solution B to solution A, at 0°C Stirring for 24 hours at a stirring rate of 700 rpm, so that the 4,4'-biphenyldisulfonic acid-linked pyrrole is polymerized and dispersed in the polyacrylic acid to form a polymer network structure.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap