Printable composite hydrogel with high toughness, preparation method and application

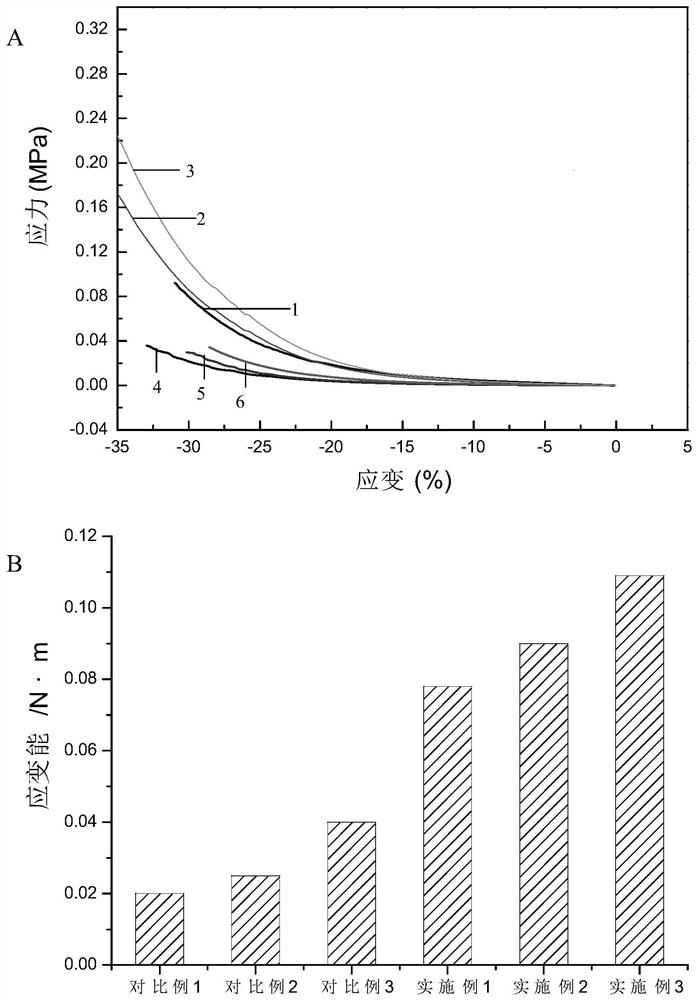

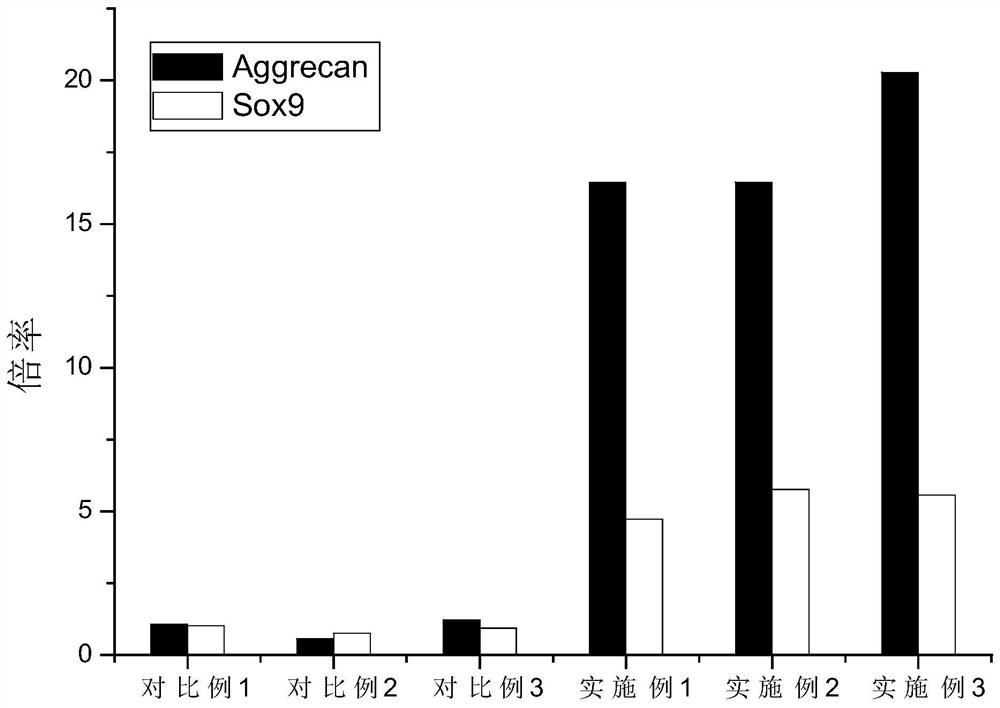

A composite hydrogel technology with high toughness, applied in the field of biomedical engineering, can solve the problems that the production technology cannot realize individualized geometry, insufficient scaffold toughness, and inability to induce and regulate cell-specific differentiation phenotypes, so as to improve cell survival High efficiency, good dispersion, and the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

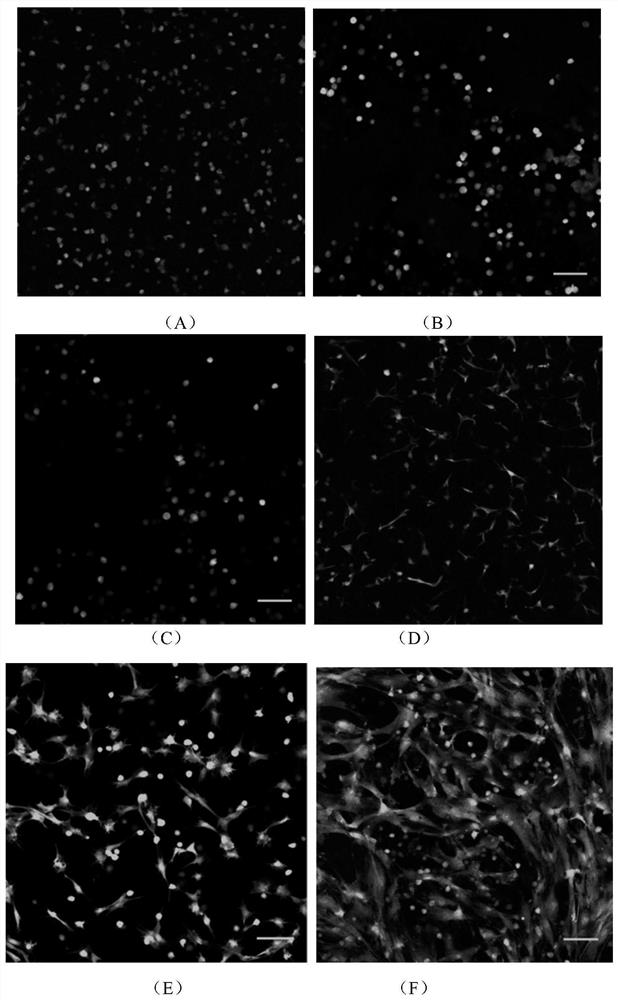

Embodiment 1

[0062] (1) Preparation of modified gelatin and modified cellulose nanocrystals:

[0063] Preparation of modified gelatin: Weigh 10 g of gelatin (Sigma company, G9382 derived from cowhide) and dissolve it in 100 mL of ultrapure water to prepare a gelatin solution with a mass concentration of 10%, then adjust the pH to 8.5 with 5 mol / L NaOH solution ; Add 7.5 mL of methacrylic anhydride dropwise, react at 40°C for 6 hours, and control the pH of the reaction solution at 8-9 through NaOH during the entire reaction process; place the product obtained by the reaction in a dialysis bag with a molecular weight cut-off of 3500 for dialysis for 3 days, freeze Dry to obtain modified gelatin.

[0064] Preparation of modified cellulose nanocrystals: Weigh 1 g of cellulose nanocrystals (purchased from Cellulose lab, Canada, containing 12% cellulose nanocrystal suspension, pore size distribution, 90-300nm, crystallization index 87%), add 0.25 g NaBr, 0.025 g TEMPO and 2.5 mL of a 12% wt NaC...

Embodiment 2

[0069] (1) The preparation of modified gelatin and modified cellulose crystals is the same as in Example 1.

[0070] (2) Preparation of composite hydrogel: 50mL of modified gelatin with a concentration of 8% by mass was prepared with ultrapure water, and the modified cellulose nanocrystals prepared in step (1) were added to make the final mass ratio 0.8% , add 60 mg of NHS, shake well, add EDC 120 mg, react at room temperature for 15 minutes, then transfer to a dialysis bag (molecular weight 3500) for dialysis for 5 days, freeze-dry, and store in a -20°C refrigerator for later use.

[0071] (3) Preparation of cell-loaded hydrogel: sterilize all materials under ultraviolet light for more than 1 h, dissolve the above-mentioned composite hydrogel in DMEM-F12 medium, and obtain a concentration of the composite hydrogel in solution A with a mass volume ratio of 8 %; add photoinitiator Irgacure 2959 (CIBA Chemicals company) solution in solution A, obtain solution B, wherein the fina...

Embodiment 3

[0074] (1) The preparation of modified gelatin and modified cellulose crystals is the same as in Example 1.

[0075] (2) Preparation of composite hydrogel: 50 mL of modified gelatin with a concentration of 8% by mass was prepared with ultrapure water, and the modified cellulose nanocrystals prepared in step (1) were added to make the final mass ratio 2.0% , add 150mg NHS, shake well, add EDC 300mg, react at room temperature for 15 minutes, transfer to dialysis bag (molecular weight 3500) for dialysis for 5 days, lyophilize, and store in -20°C refrigerator for later use.

[0076](3) Preparation of cell-loaded hydrogel: sterilize all materials under ultraviolet light for more than 1 h, dissolve the above-mentioned composite hydrogel in DMEM-F12 medium, and obtain a concentration of the composite hydrogel in solution A with a mass volume ratio of 8 %; add photoinitiator Irgacure 2959 (CIBA Chemicals company) solution in solution A, obtain solution B, wherein the final concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com