Composite de-foaming agent applicable to sodium aluminum silicon glass and application method thereof

A composite defoamer and silica glass technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of the improvement of the defoaming effect of pentamethylene iron, the increase of iron content in liquid crystal glass, and the inappropriate use of large-scale use. and other problems to achieve the effect of reducing influence, reducing local viscosity and surface tension, and promoting bubble collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

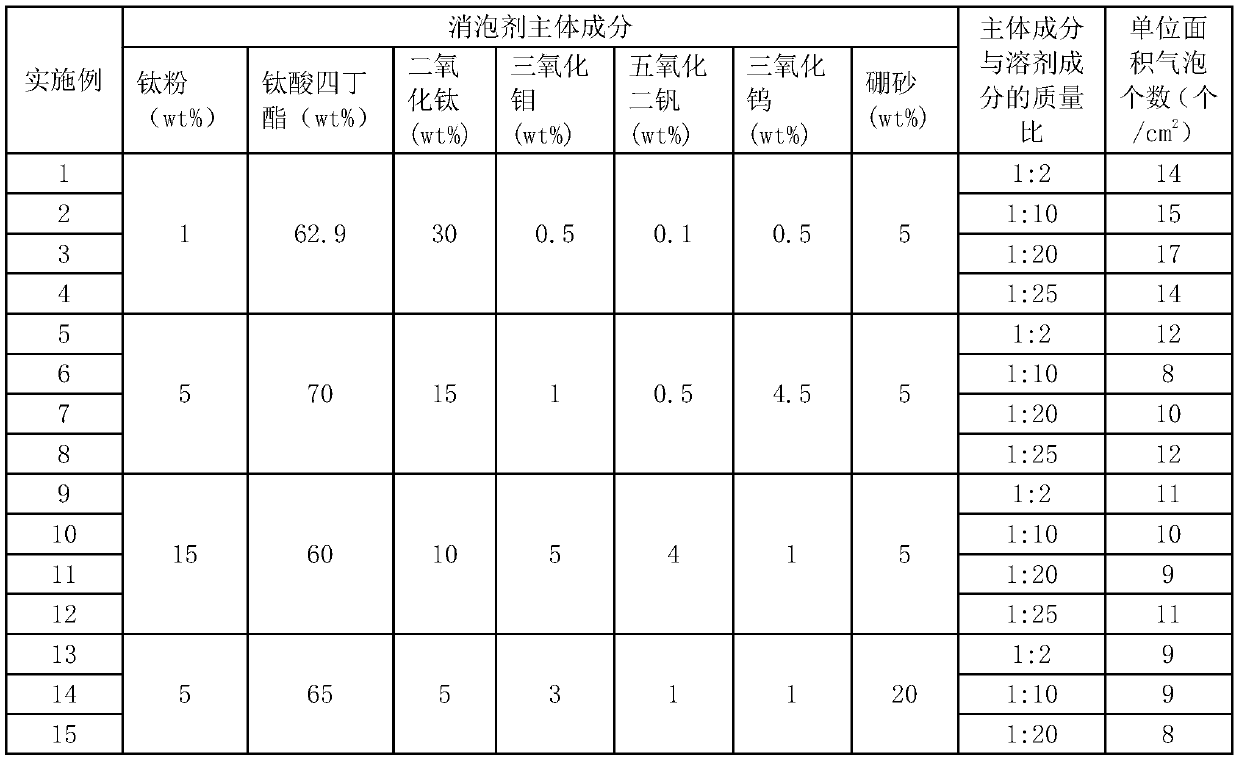

[0031] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the present invention is not limited to the following examples.

[0032] In the following examples, the components and mass percentages of the chemical composition of the glass used are: SiO 2 65wt%, Al 2 o 3 15wt%, CaO 4wt%, Na 2 O 16wt%, Fe 2 o 3 ≤300ppm. The types and amounts of raw materials (glass batching samples) are: 262.63 grams of high-purity quartz sand, 60.61 grams of alumina powder, 28.96 grams of calcium carbonate powder, and 110.94 grams of sodium carbonate powder.

[0033] A kind of composite defoamer suitable for sodium aluminum silicate glass of the present invention (i.e. defoamer, see Table 1) consumption is 232.07 milligrams (0.05wt% of adopting raw material weight); Described solvent is aviation kerosene.

[0034] Prepare a uniformly mixed glass batch sample according to the above weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com