Insulating heat-conducting adhesive film for heating device and heating device made of insulating heat-conducting adhesive film

An insulating and thermally conductive adhesive, heating device technology, applied in ohmic resistance heating parts, ohmic resistance heating, film/sheet without carrier, etc., can solve hidden dangers, poor heat resistance of adhesive layer, reduce heating efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 7、 comparative example 1 to 5

[0072] The preparation method is as follows:

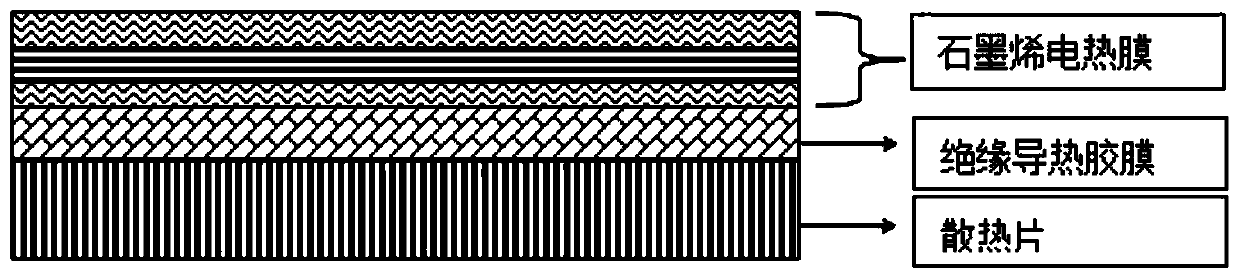

[0073] (1) Preparation of graphene electrothermal film:

[0074] According to the general method of public information, first mix 90 parts of polymer film-forming resin vinyl resin, 10 parts of diluent absolute ethanol, 10 parts of graphene, and additive dodecylbenzenesulfonic acid sodium salt 0.2 parts, and mix evenly to obtain graphite Graphene resin mixture (graphene needs to be dispersed before use, and the dispersion method is ultrasonic dispersion in absolute ethanol for 30 minutes), and then the graphene conductive material is formed on the polyimide carrier by printing or spraying or coating. layer, and then dried to obtain a graphene conductive layer, electrodes are placed on the edge of the graphene layer, and a layer of polyimide insulating protective film with adhesive is attached on the graphene layer to make a graphene electric heating film .

[0075] (2) Preparation of heating device:

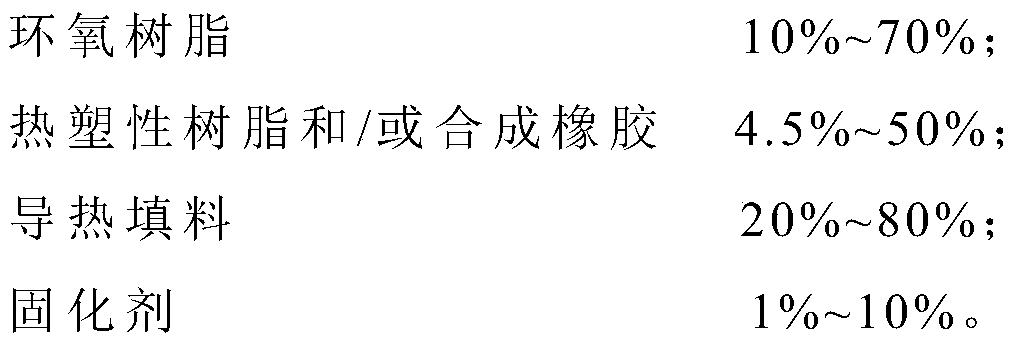

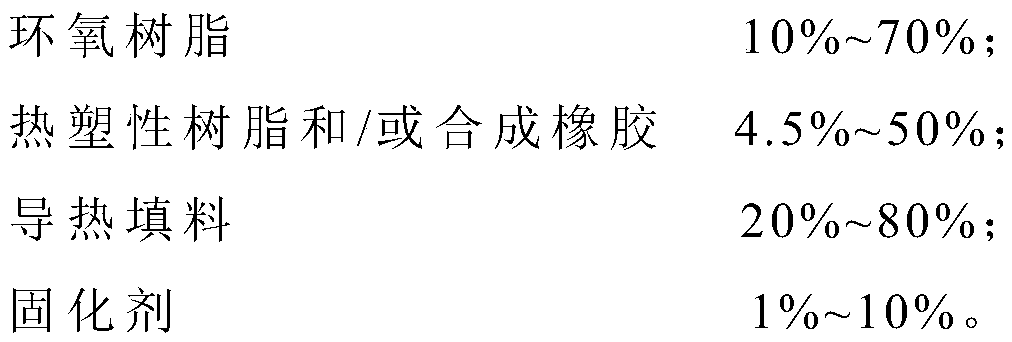

[0076] Dissolve epoxy resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com