A fire-proof and heat-insulating lightweight wallboard and its production process

A light-weight wallboard and embedded layer technology, which is applied in the direction of fire protection, walls, and manufacturing tools, can solve the problems of low overall strength of light-weight wallboards, poor fireproof and heat insulation effects, and normal service life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

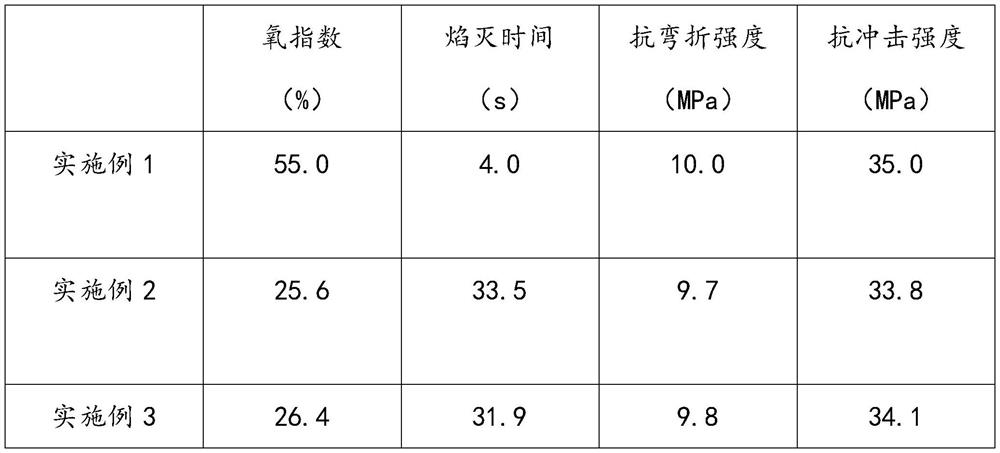

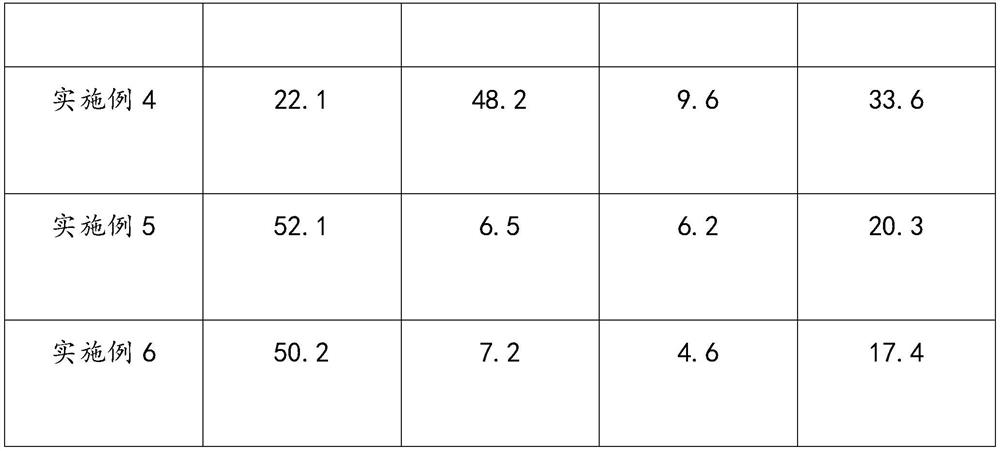

Examples

Embodiment 1

[0026] A fire-proof and heat-insulating lightweight wallboard, comprising an integral layer and an embedded layer, the embedded layer is evenly arranged in the integral layer, the embedded layer is a modified grid cloth, and the length, width and thickness are respectively 50 mm , 50 mm and 2.5 mm;

[0027] The modified mesh cloth is produced by the following steps: first cut the mesh cloth to the required size, then repeatedly polish both sides of the mesh cloth with sandpaper until fluffy short fibers appear, and then place it in a 75-degree Soak in styrene-butadiene latex for 30 minutes, then take it out and use a steel needle to evenly pierce the pinholes, and after drying and cooling, to obtain a modified mesh cloth with a gel-like interlayer attached to the surface;

[0028] The raw materials in the overall layer are respectively 30% Portland cement, 15% cinder, 15% slag, 15% sawdust, 7.5% borax, 7.5% glass fiber, 5% Sodium rosinate and 5% modified flame retardant addit...

Embodiment 2

[0038] A fire-proof and heat-insulating lightweight wallboard, the difference from Example 1 is that the modified flame-retardant additive is prepared by the following steps: first, 2-ethyl ethanol, propylene alcohol and phosphorus oxychloride Add together in the reaction kettle for mixing, and the temperature in the reaction kettle is controlled at 5 degrees. After stirring for 5 minutes, it is initially heated to 20 degrees and kept for 30 minutes, and then raised to 40 degrees for the second time and kept for 30 minutes. Add liquid bromine to the reaction kettle and keep it for 15 minutes, and finally pass through ammonia water and wash with water, distill and cool to obtain a modified flame retardant additive;

[0039] The raw materials in the modified flame retardant auxiliary agent are respectively 20% of 2-ethyl ethanol, 20% of propylene alcohol, 45% of phosphorus oxychloride and 15% of liquid bromine by weight percentage.

[0040] A production process of a fire-proof a...

Embodiment 3

[0042] A fire-proof and heat-insulating lightweight wallboard, the difference from Example 1 is that the modified flame-retardant additive is prepared by the following steps: first, 2-ethyl ethanol, propylene alcohol and phosphorus oxychloride Add them together to the reaction kettle for mixing, and the temperature in the reaction kettle is controlled at 5 degrees. After stirring for 5 minutes, it is initially heated to 20 degrees and kept for 30 minutes, and then raised to 40 degrees for the second time and kept for 30 minutes. After that, the When the temperature of the reaction kettle is lowered to 10 degrees, sodium phenate is introduced, and kept at 50 degrees for 30 minutes, and finally ammonia water is introduced and washed with water, distilled and cooled to obtain a modified flame retardant additive;

[0043] The raw materials in the modified flame retardant auxiliary agent are respectively 20% of 2-ethyl ethanol, 20% of propylene alcohol, 45% of phosphorus oxychloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com