T-Nb2O5/egg white carbon composite material used for lithium ion supercapacitor as well as preparation method thereof

A carbon composite material, t-nb2o5 technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of low efficiency utilization of Nb source precursors, harsh experimental synthesis conditions, etc., and achieve increased Effective specific surface area, ease of stacking agglomeration, and enhancement of environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

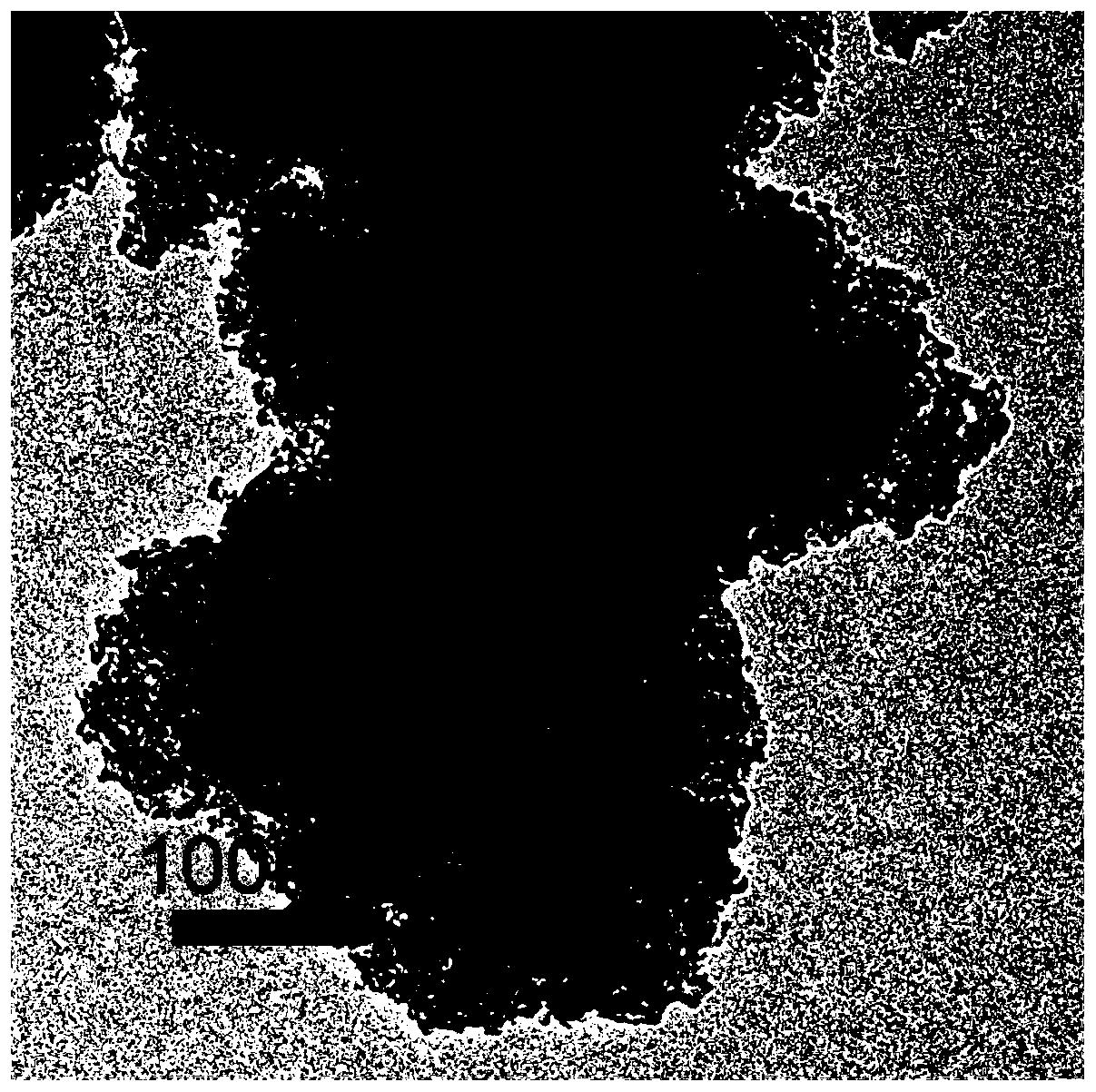

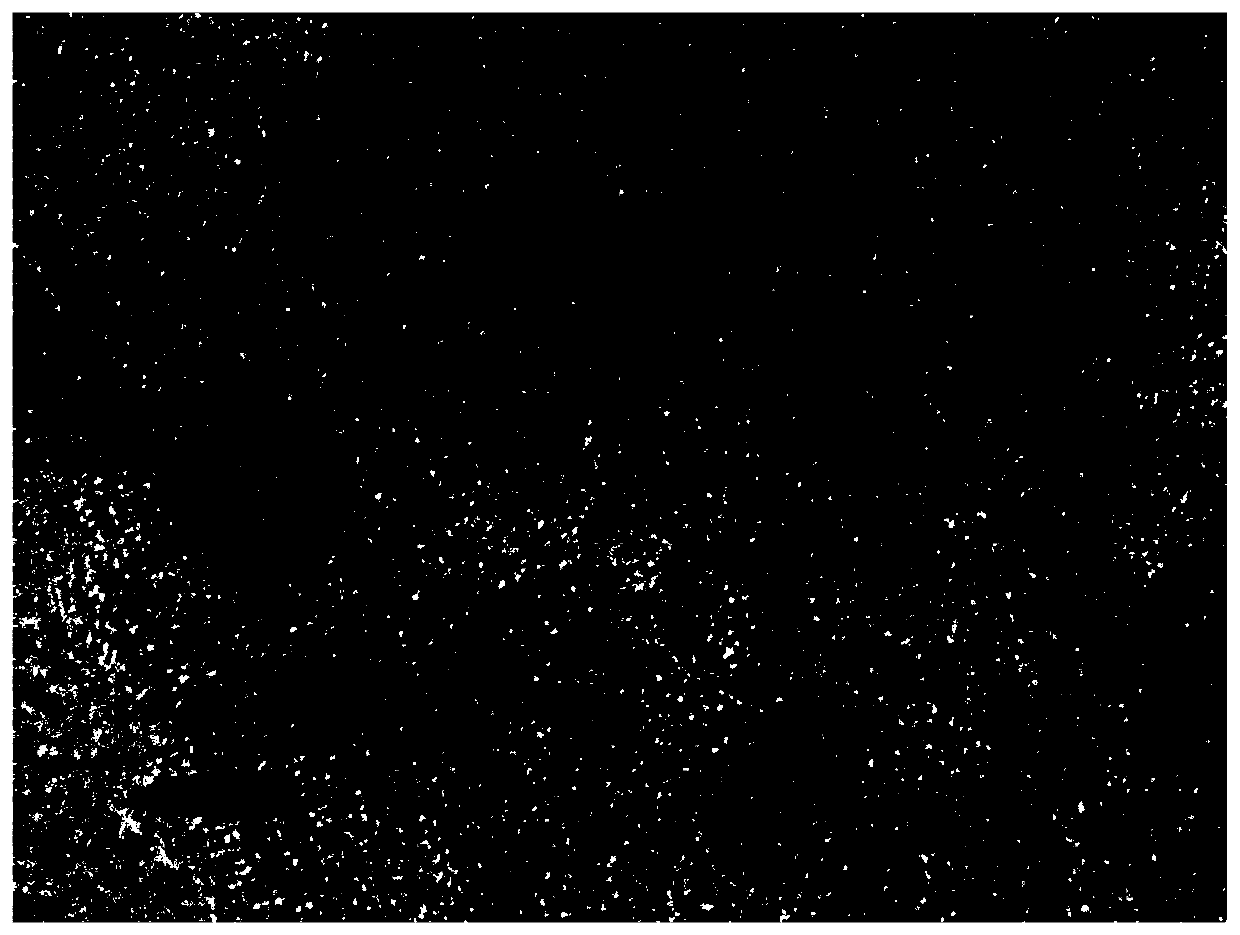

[0037] 1) Egg white pretreatment: remove the egg yolk and keep the egg white, stir well and set aside.

[0038] 2) 0.2 g ammonium niobate oxalate hydrate (C 4 h 4 NbO 9 ·xH 2 O; 99.99%) was added to 10 mL of deionized water, stirred and then added to 60 mL of egg white, 0.5 mL of 2 mol / L HCl was added dropwise, and the solution was stirred for 30 min until milky white, and the mixed emulsion was transferred into a 100 mL hydrothermal reaction kettle .

[0039] 3) Put the reactor into an oven, conduct a hydrothermal reaction at 180°C for 24 h, cool down to room temperature naturally, filter and freeze-dry the brown precipitate to obtain a mixture.

[0040] 4) Put the mixture into a crucible, move it into a tube furnace under a nitrogen atmosphere, raise the temperature to 700°C at a heating rate of 2°C / min, and keep the temperature constant for 2 hours to obtain a composite product.

[0041] 5) Wash with deionized water and absolute ethanol several times, dry and grind to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com