Sodium ion battery negative electrode material and preparation method thereof

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of electrode material shedding, large volume change, battery performance attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

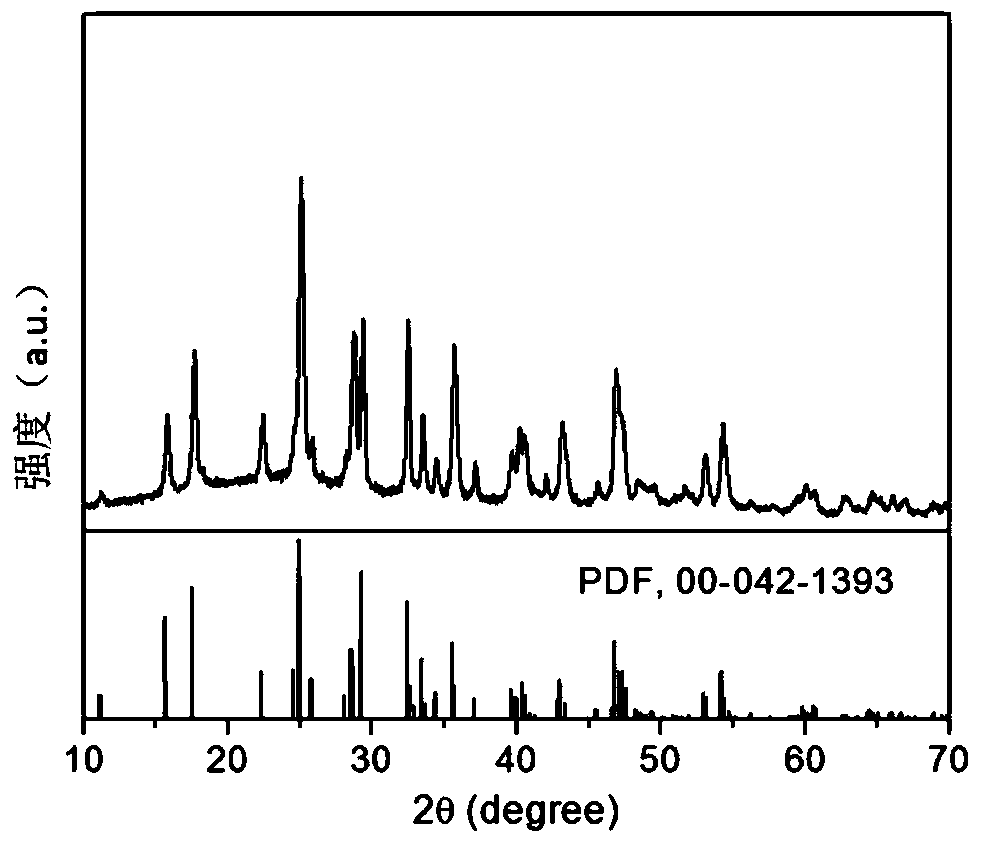

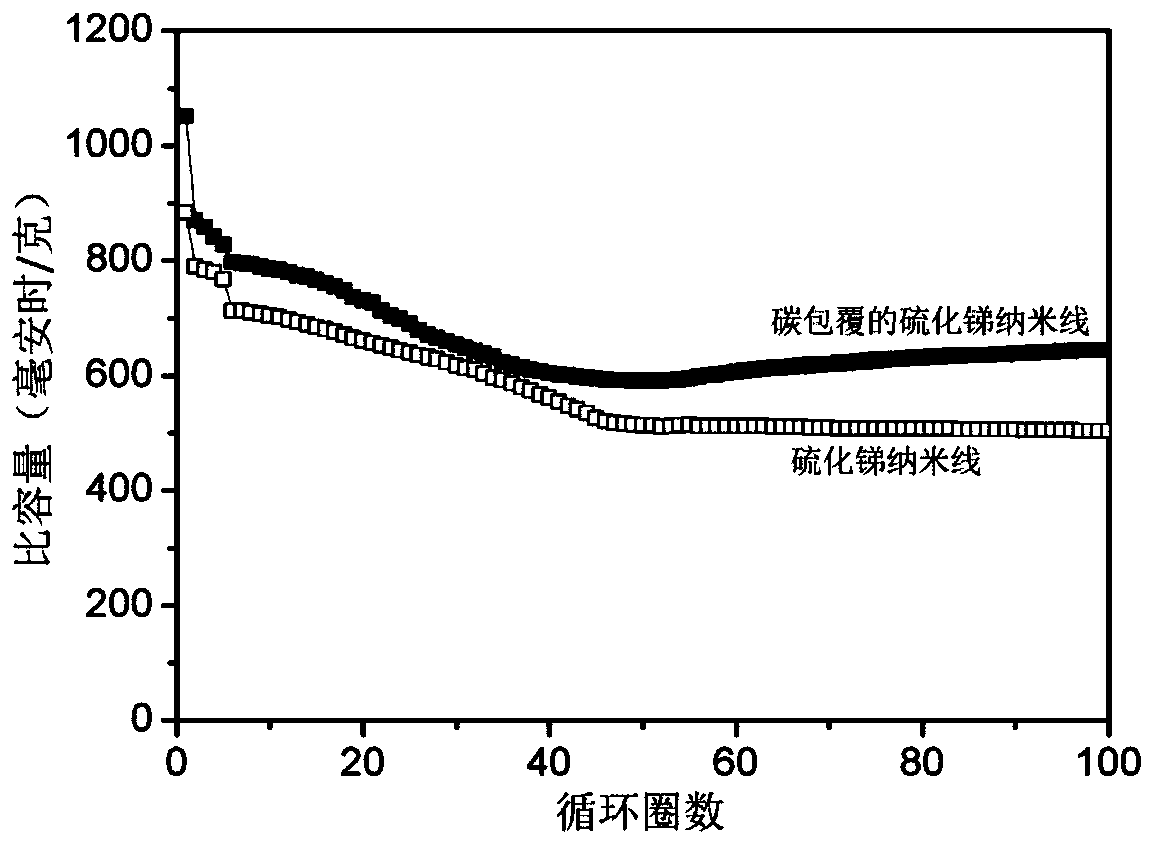

[0041] The negative electrode material of the sodium ion battery is a composite material formed of a nitrogen-doped carbon layer coated with an antimony sulfide nanowire.

[0042] The preparation method of the negative electrode material of the sodium ion battery comprises the following specific steps:

[0043] (1) Preparation of antimony sulfide nanowires: First, 0.228g of antimony chloride and 0.48g of sodium sulfide nonahydrate were dissolved in 20mL of ethylene disulfide

[0044] In alcohol, obtain the ethylene glycol solution of antimony chloride and the ethylene glycol solution of sodium sulfide nonahydrate;

[0045] The ethylene glycol solution was dropped into the ethylene glycol solution of sodium sulfide nonahydrate for mixing, and the obtained mixed solution was stirred for 3 hours to form a uniform solution, and the solution was placed in a 50 mL autoclave with a polytetrafluoroethylene substrate , heated at 200°C for 10h, cooled to room temperature, collected the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com